Snapshot

Sterling Noren, TunnelTalk

| Project: | Alaskan Way Viaduct replacement tunnel, Seattle |

| Contractor: | Seattle Tunnel Partners Dragados - Tutor Perini JV |

| Client: | WSDOT |

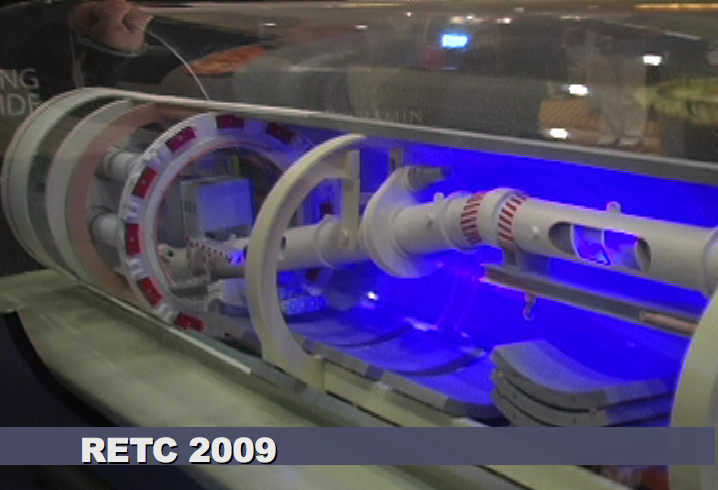

| TBM supplier: | Hitachi Zosen 17.48m EPBM |

| Date of breakdown: | December 2013 |

| Nature of problem: | Machine overheating |

| Diagnosis: | Ruptured bearing seals |

| Bearing manufacturer: | Rothe Erde of Germany |

| Replacement bearing: | Spare bearing available as part of the contract |

| Access method: | 24m diameter x 36m deep (80ft x 120ft deep) recovery shaft Started in May 2014 Completed Feb 2015 |

| Revised schedule: | Repairs to be completed and anticipated restart of boring by August 2015 |

| Original contract delivery date: | November 2016 |