Long drive TBM celebrations in Malaysia

23 Apr 2013

Desiree Willis, Technical Writer, The Robbins Company

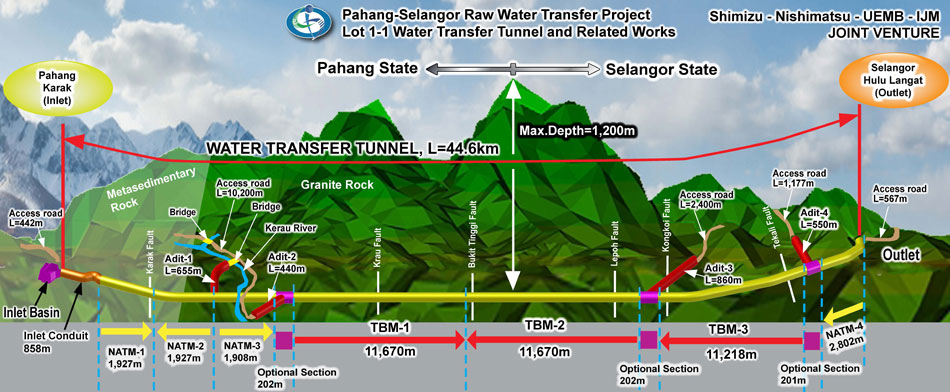

- A drive of 11km through the mountains of Malaysia came to an end on March 22, 2013, when the first of three 5.23m diameter Robbins gripper TBMs working on the Pahang Selangor Raw Water Tunnel project broke through.

-

First breakthrough celebrations after a long 11km journey

- It was a moment worthy of celebration as it marked a significant step towards completing the 44.6km water transfer route to bring potable water from the State of Pahang to the Kuala Lumpur urban region in the State of Selangor.

- "This is a day we all look forward to in the tunneling industry," said Andy Birch, Robbins Field Service Manager. "It is a good feeling when you get through all of the hard work and eventually break through."

- The breakthrough, to complete the upstream section of the longest tunnel in southeast Asia, was attended by dignitaries, contractors and honored guests, with everyone very enthusiastic about the success of the TBM and its crews.

- Many challenges were overcome by the TBM and its continuous conveyor system on the 11km run, including blocky rock, over-break, power outages, extremely high rock temperatures and high water inflows. Robbins field service has worked closely with the contractor, a joint venture of Shimizu Corporation, Nishimatsu Construction, UEM Builders, and IJM Construction (SNUI). "I am very happy with the achievement and for the construction joint venture, and they seem very happy too," said Birch.

-

Fig 1. The remaining two TBMs are heading towards each other from Adits 2 and 3

- Despite the variable conditions, the TBM maintained strong advance rates of 475m/month on average. "Maximum advance rates were in excess of 650m/month," said Kenji Ohashi, Senior Mechanical and Electrical Engineer for the SNUI JV. "That is an advance of 30m/day on average."

- Various methods of support were used during excavation, one of the most extensive being the near-zero rebound application of low pressure sprayed fiber mortar. The Pahang Selangor project marks the first time that this innovative method has been used outside of Japan, and it has been very successful so far.

-

Low-pressure spay-applied mortar support

- The mortar can be applied during excavation directly behind the cutterhead support, which greatly reduces project downtime. The method also boasts the benefits of dust reduction and good bonding.

- The two remaining 5.23m machines working towards each other from Adits 2 and 3 are more than 9km into their 11km long drives and are on schedule to make an in-tunnel junction in Autumn 2013.

- Upon completion, the tunnel will transfer 27.6m3/sec of water to a new treatment plant that will feed drinking water into the distribution network of the Kuala Lumpur city region. The system will supply water to about 7.2 million people for project owner KeTTHA (the Malaysian Ministry of Energy, Green Technology, and Water).

-

Mountain drives for water supply in Malaysia - TunnelTalk, April 2012

Predicting rock conditions ahead of the face - TunnelTech, September 2012

Malaysian raw water tunnel awarded - TunnelTalk, May 2009

Robbins trio to team up in Malaysia - TunnelTalk, November 2009

Robbins launch on Malaysia's mega water project - TunnelTalk, February 2011

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.