CROSSRAIL

SCL to create Crossrail junction caverns

Sep 2012

Shani Wallis, TunnelTalk

- Click on the logos to enter the websites of those who have opened the door for direct access and exploration

-

Major engineering and contracting companies engaged on the Crossrail project to November 2011

Major engineering and contracting companies engaged on the Crossrail project to November 2011

Hot! -

Programme Partner - Transcend, a JV of:

-

Project Delivery Partner - Crossrail Central,

a team of:

- CONTRACT PACKAGES

- DESIGN PACKAGES

|  |  |

|  Hot! |  |

| Contract | Package description | Engaged constructor |

| C300 | Running Tunnels West - Royal Oak to Farringdon |

|

| C410 C435 | Bond Street and Tottenham Court Road Station early access shafts works Farringdon Station |

|

| C305 | Running Tunnels East - Limmo Peninsula to Farringdon; Limmo Peninsula to Victoria Dock; Stepney Green to Pudding Mill Lane |

|

| C405 C330 C248 | Paddington Station Royal Oak Portal Civils Pudding Mill Lane Portal TBM reception chamber |

|

| C510 C512 | Whitechapel and Liverpool Street early access shafts and works Whitechapel Station |

|

C502 | Canary Wharf station delivery by sub-partner Canary Wharf Group Liverpool Street Station |

|

| C701 | Instrumentation Monitoring |

|

| C200 | Pudding Mill Lane - Site Facilities |

Hot! |

| C210 | Liverpool Street Station Advance Works Package 2 |

|

| C245 | Whitechapel Station Civils, Demolition & Utilities |

|

| C240 | Bond Street - Civils |

|

| C244 | Whitechapel Station Civils 1 - Steel Deck Over East London Line |

|

| C271 | Paddington Integrated Project - Advanced works |

|

| Contract | Package description | Engaged firm |

| C100 | Architectural Component Design |

|

| C146 | Custom House Station | |

| C102 | Material & Workmanship Specification |

|

| C121 | Sprayed Concrete Lining | |

| C124 | Railway Systems & Tunnel M&E Services | |

| C131 | Paddington Integrated Project | |

| C138 | Liverpool Street Station | |

| C122 | Bored Tunnels - Alignment & Track |

Hot! |

| C134 | Tottenham Court Road | |

| C123 | Intermediate Shafts |

Hot! |

| C130 | Paddington Station |

|

| C136 | Farringdon Station | |

| C152 | Pudding Mill Lane | |

| C164 | Bulk Power Distribution & HV System | |

| C132 | Bond Street Station |

|

| C140 | Whitechapel Station |

|

| C154 | Victoria Dock Portal | |

| C150 | Royal Oak Portal |

|

| C156 | North Woolwich & Plumstead Portal | |

| C170 | Communications & Control System |

Hot! |

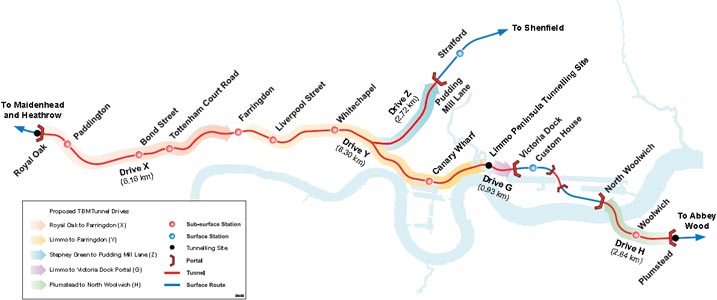

- Caverns of up to 17m high x 16.5m wide are to be excavated under the East End of London at Stepney Green to create the underground rail track junctions on the city’s Crossrail project that will permit train services to run either north towards Stratford or south towards Canary Wharf (Fig 1).

-

SCL for Drives Z and Y junction cavern under Stepney Green

- Designed as SCL (sprayed concrete lining) structures, the twin caverns are claimed as among the largest caverns excavated in soft rock or soft ground conditions in Europe. With single track TBM tunnels arriving at the caverns from the west, the end wall of the 120m-long Y shaped caverns to the east will accommodate the eyes of twin 7.1m o.d. TBM running tunnels serving the two track directions. At the central widest point of the Y excavations, the cavern dimension will be 17m high x 16.5m wide, off which the two shorter legs will extend.

- Excavation of the caverns will progress from a rectangular access shaft built across the twin TBM running tunnels to the west of the junctions that will double to house M&E utility rooms, a ventilation facility and an emergency ingress and egress for Crossrail in operation. The shaft and the caverns are significant elements of contract C305 which centres on excavation of 8.3km of segmentally lined running tunnels from Victoria Docks Portal in the southeast and Pudding Mill Lane Portal in the northeast, through the junctions at Stepney Green and on to the contract interface at the west end with the underground Farringdon Street Station caverns of contract C435.

-

Scope of the Dragages/Siske C305 contract with the Stepney Green junction at the mid point

- As the largest construction contract on the Crossrail project, the Eastern Running Tunnels Contract C305 was awarded to the Spanish/Irish Dragados/Sisk JV in December 2010 for about £500 million. Using four of the eight Herrenknecht TBMs to be used on the project, the first two for the JV will launch from the Limmo Peninsula job site and head west towards the Stepney Green junction cavern, passing through the Canary Wharf Station box enroute and continuing to finish the second leg of the running tunnels at Farringdon, passing through the underground station cavern works of other contractors at Whitechapel and Liverpool Street Stations.

- Another two TBMs will launch from Pudding Mill Lane Portal to head also to the second of the Stepney Green junction caverns. The first to arrive will be transported to the Limmo work site to complete the two short C305 drives to Victoria Dock Portal.

- At a site visit for the press to the Stepney Green job site, Peter Main, Project Manager for Contract 305 for Crossrail Ltd, explained how the contractor took possession of the site in March 2010 to set up and start excavation first of the large access and operations shaft. Diaphragm slurry walls of up to 40m deep around the 15m wide x 60m long shaft replaced the 1.2m thick diaphragm walls with rebar reinforcement cages and up to 9,500m3 of tremmied concrete.

- At the time of the visit in early September 2012, core excavation of the 36m deep shaft, through quality London Clay, had reached a level at about the top of the running tunnel eyes and had another 10m or so to go. A blind concrete base slab had been cast into the shaft to finish construction of permanent interior reinforced bracing beams ahead of taking the shaft to depth and installing temporary bracing props. Once the full 31,000m3 of clay is excavated from the shaft and the permanent base slab is cast, the SCL headings will breakout from the tunnel eyes and excavation, using excavators, and will progress 24h/day, 7 days/week. The caverns have to be completed before the running tunnel TBMs arrive from Limmo for pull-through to continue their journey to Farringdon.

- At the site visit presentation Main explained that the caverns are a major challenge on contract C305. "They are the largest caverns excavated in the UK except for the crossover chamber on the Channel Tunnel, which is slightly larger. The SCL excavations are designed on a topheading, bench and invert sequence, dividing into single and double side-wall drifts as the span increases to its widest point."

-

Shaft excavation down through London Clay

- Supporting the SCL excavation – and "it is certainly SCL," explained Fintan Cawley, Site Engineer for Crossrail whose first career move this is after graduating from university - are 45 x 50m deep dewatering wells. Rather than dewatering the clay, these are dewatering sedimentary layers deeper beneath the base level of the shaft and caverns. Installed also are 60 geo-instruments set into 50m deep boreholes to monitor movement around the caverns as excavation of the 20,000m3 of material is completed.

- Material from Stepney Green is transported by truck to a marshalling point where muck is then transferred to barges for onward disposal at Wallasea Island in the River Thames Estuary. This location is where most of the excavated material for Crossrail will be disposed of. Once through the Stepney Green junction, mucking out behind the continuing TBMs will be hauled by continuous conveyor back to Limmo for loading directly onto the barges. All service of the continuing TBMs will continue from Limmo. That includes supply of the 30,000 lining segments, which are to be delivered on barges from the twin-carousel casting factory in Chatham on the Medway River in Kent. Each barge will carry one ring of seven segments per ring per trip and there will be one round trip per barge per day. As well as taking account of the tidal influence of the river, there is also the need to manage heavy Crossrail barge traffic along with all other traffic on the river. Up to five barges a day will be on the river hauling tunnel muck from the excavations to Wallasea by Contract C807 contractor Marine Transportation, a JV of BAM Nuttall and Van Oord UK Ltd.

-

SCL cavern excavation will extend under the city farm

- The Stepney Green access shaft is in a famous part of historic London near the Green and close to urban infrastructure. Its closest neighbour is a large school of 1,800 pupils; streets of refurbished and new terraced houses directly adjacent the Stepney Green City Farm, owned by Tower Hamlets Borough Council and leased and managed by a charity organisation. In return for taking over a third of the farm's area for the job site for the duration of the contract and keeping part of that land as the site of the shaft's head house, Crossrail has paid about £1million to build a new barn and new workshops, renovated the farm's fences and paths and generally established itself as a good neighbour. For the school, Crossrail has agreed not to run truck traffic on the streets at the start and end of the school day, and for close residents windows have been double-glazed for noise control.

- In closing his presentation Peter Main commended the C305 contractor on its management of the Stepney Green site; its liaison with the community and local authorities; and its progress of the works since arriving on site in March 2010, which were reported as being two weeks ahead of schedule when we visited. For the farm and its animals and works, excavation of the SCL junction caverns are to progress directly beneath them and they are assured all will be well.

-

Crossrail awards tunnelling contracts - TunnelTalk, December 2010

All Crossrail TBMs in the Herrenknecht basket - TunnelTalk, September 2011

Monitoring contract for Crossrail - TunnelTalk, June 2010

Rekindled NATM debate-SCL debate opens - TunnelTalk, August 2012

Channel Tunnel in hindsight - TunnelTalk, February 1993

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.