Financing milestone for Sirius potash project 06 Sep 2016

UK potash mine developer Sirius Minerals has taken a significant step towards delivering a US$15 billion asset capable of generating US$2.5 billion a year in revenue – including the likely support of the UK Government in the form of loan guarantees.

The company needs to secure US$3.9 billion worth of funding before it can begin sinking the 1.6km-deep mine shaft to gain access to one of the world’s largest reserves of the crop nutrient polyhalite.

Explaining the construction concepts of the York Potash Project

In an update to the London Stock Exchange last week the company announced that six major financial institutions have come on board as Mandated Lead Arrangers (MLAs) and will themselves look to contribute US$700 million of the required US$2.6 billion of senior debt needed to fund Phase 2 of the project in 2018 – which includes the 37km tunnel, fit-out, installation of the conveyor system and construction of the port facilities in Redcar on the north east coast of England.

In a market update Sirius said: “Following a market sounding with potential senior debt lenders the company (Sirius) has now mandated a group of six financial institutions experienced in mining and infrastructure project finance, as Mandated Lead Arrangers (MLAs). Export Development Canada (EDC), ING, J.P. Morgan, Lloyds Bank plc, Societe Generale, Corporate & Investment Banking and The Royal Bank of Scotland Plc have been mandated on the basis of a non-binding but mutually agreed term sheet, having undertaken initial due diligence of project documents.

“The UK Infrastructure and Projects Authority (IPA), which was established in January 2016 by merging the Major Projects Authority with Infrastructure UK, and reports jointly to both the Treasury (HMT) and the Cabinet Office, has already prequalified the project for consideration for a HMT Guarantee. IPA has discussed the Stage 2 financing plan with the company and confirmed its interest in supporting the Stage 2 financing for the project.”

Involvement of the six major institutions is likely to make raising the US$1.1 billion needed to fund development of the mine in Phase 1 significantly easier. Sirius has said it intends to raise this money through a mix of debt and new equity issue, and an announcement on this is expected before the end of October if the timeline of a March 2017 start is to be maintained.

Sirius said: “The company intends to progress the Stage 2 financing, with the MLAs and IPA commencing detailed due diligence, following the successful completion of the Stage 1 financing. The company continues to progress the Stage 1 financing and is in active discussion with a number of parties undertaking due diligence. The details of the Stage 1 capital structure and timing will be subject to further announcement at an appropriate time.”

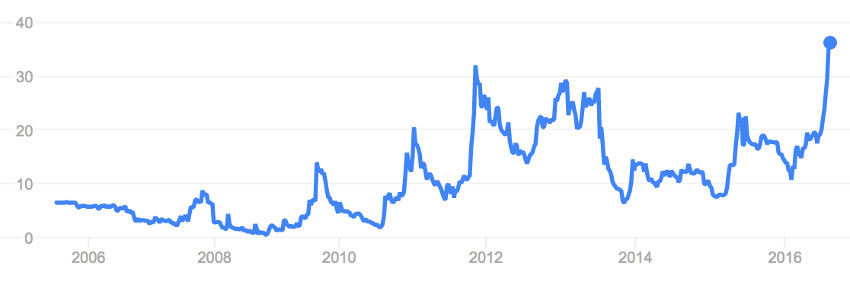

In the lead up to the latest financing announcement shares in Sirius reached a peak of 52p, before settling back to 40p.

Sirius CEO and MD Chris Fraser, who owns 124 million of the 2.3 billion shares in issue, said: “The company is now focused on the finalisation of the Stage 1 financing to enable construction to commence as soon as possible. This positive step on the senior debt financing should provide Stage 1 investors with greater clarity and confidence on the total financing of our world class fertilizer business.”

UK potash mega-project design changes 17 Aug 2016

Significant design and engineering modifications are made to the excavation strategy for the UK’s longest planned tunnel.

Instead of five TBMs, the strategy for excavation of the 37km long polyhalite (potash) mineral transportation system (MTS) of the York Potash Project now calls for three TBMs. Construction risk is also reduced by cutting the number of deep-level intermediate shafts from three to one (Fig 1).

The changes – which mean the previously planned and permitted shafts at Lady Cross (362m) and Tocketts Lythe (144m) are no longer required – will result in the tunnel being excavated in three almost equal-length 12km drives. Additionally, it has been decided to construct the whole length of the tunnel using a concrete segmental lining between the cavern excavations at the bottom of the main shaft at Dove’s Nest minehead and the intermediate shaft at Lockwood; and between the Lockwood shaft and the portal at Wilton.

The owner’s construction design team includes Arup (tunnel and tunnel shafts), WorleyParsons, Royal Haskoning, Home International and SRK Consulting, with Bechtel managing production of a detailed Definitive Feasibility Study (DFS) to inform the critical finance-raising aspect of the project.

Selected MTS tunnel contractor Hochtief/Murphy is expected to begin on-site preparatory works within six months of the conclusion of the capital-raising exercise that is now believed to be in its final stages. Sirius Minerals – owner of the York Potash Project – announced earlier this week that it only has £16 million of capital reserves remaining to fund the project, but said that during the last six months it had “set the platform for the advancement of our financing strategy”. Sirius Minerals chief executive Chris Fraser, who was part of the team that propelled Fortescue of Australia from penny-share status to global mining giant, has said recently that he expects the project to be “shovel ready” next month (September 2016).

Market speculation has been mounting as to when the identity of the “cornerstone” partner/investor for the project will be released, along with details of the debt/equity split of the US$1.1 billion that is required to move the project into its first phase of construction.

This phase includes the majority of works associated with excavation of the production and service shafts of the minehead (awarded to Thyssen/Redpath), as well as the two MTS tunnel shaft excavations (Dove’s Nest and Lockwood) and portal works (Wilton).

The US$1.8 billion cost of Phase 2 of construction will include the majority of the TBM excavations and tunnel fit-out, the outstanding balance of works needed to complete the minehead, and the mineral processing/port facility at Redcar – permission for which was granted by the UK Government last month (July 2016) but for which a six-week objection period is still active for another two weeks. Once this window is passed Sirius Minerals will have in place all the final permissions it needs to move to construction, subject to finance.

According to the latest construction schedule released by the owner, Hochtief/Murphy will begin site preparation and shaft sinking at Dove’s Nest and Lockwood once six months of mandatory highway improvements are completed. These shaft sinking works are expected to take two years. TBM assembly, excavation of the 4.1m i.d. segmentally lined tunnel, cavern construction, and fit-out is scheduled to take a further three years – to run alongside the separate contract to excavate the 1,600m deep production and service shafts.

Over the last few weeks speculation in Sirius Minerals on the London Alternative Investment Market (AIM) exchange has intensified sharply, with shares now trading at a record high of 36p, up sharply from the 10p they traded at as recently as February (2016) and 72 times higher than the 0.5p they traded in the project’s early 2009 days (Fig 3).

Once completed, the mine will have an initial capacity of 10 million tonne per annum (mta), much of which has already been pre-sold under various offtake agreements spanning 5-8 years. This will be ramped up to 13mta (the maximum currently permitted), but the tunnel and conveyor system will have an installed capacity of 20mta to meet possible future demand.

Following a seven-year construction schedule, Sirius Minerals anticipates the mine will start generating cash in 2023/24, and at full capacity in 2030 will be generating US$3 billion a year. As an additional revenue stream, the company says future roadheader construction of a 1,500m-long access ramp from the main polyhalite seam will expose a significant reserve of salt for export for de-icing.

References

- Sirius Minerals July 2016 Investor presentation

- Civils awarded for UK’s longest tunnel – TunnelTalk, June 2016

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.