Shortlist for Hampton Roads subsea link 03 May 2018

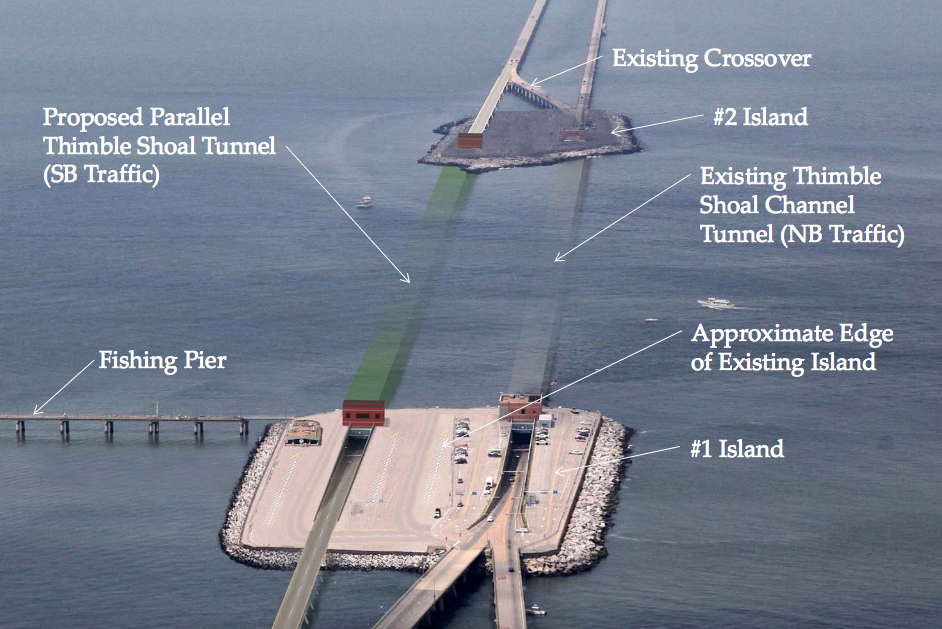

Three private-sector teams are shortlisted to submit proposals to design and construct the Hampton Roads Bridge-Tunnel expansion project across the mouth of Chesapeake Bay for the Virginia Department of Transportation (VDOT). The proposal invitation is for either a bored tunnel or immersed tube option to provide four parallel carriageways to expand capacity of the two existing 7,500ft-long (2.2km) two-lane immersed tube crossings between the man-made islands and the trestle bridge connections either side to landfalls in the cities of Norfolk and Hampton (Fig 1).

Both construction methods are currently under consideration and the three teams – pre-qualified to build either or both tunnel types - will be invited to submit detailed technical proposals and binding design-build prices for one construction method. Following a request for proposals (RFP) set for May 2018, proposals will be due by Fall 2018.

The shortlisted private-sector teams and their selected qualified construction methods are:

Hampton Roads Capacity Constructors

Shortlisted for TBM bored tunnel and immersed tube tunnel methods

Lead contractors: Fluor Enterprises / The Lane Construction Corp / Traylor Bros / Dragages

Lead designer: AECOM Technical Services

Design support: Michael Baker International / Royal HaskoningDHV and Witteveen+Bos JV / Mueser Rutledge Consulting Engineers

Hampton Roads Connector Partners

Shortlisted for TBM bored tunnel and immersed tube tunnel methods

Lead contractors: Dragados USA / Vinci Construction Grands Projets / Dodin Campenon Bernard JV

Lead designer: I-64 Design JV of HDR Engineering / Mott MacDonald

Design support: Whitman Requardt and Associates / Harris Miller Miller & Hanson / Precision Measurements / AI Engineers / GET Solutions / Mattern & Craig / Athavale Lystad & Associates / Diversified Property Services

Skanska Kiewit Joint Venture

Shortlisted for an immersed tube tunnel

Lead contractors: Skanska USA / Kiewit

Lead designer: WSP USA

Design support: COWI / Vanasse Hangen Brustlin / CAPITA

“These candidate teams are strong contenders for the next steps in the competitive process,” said Stephen C Brich, VDOT Commissioner. “We are looking forward to learning more about each team’s specific plans and capabilities to deliver this vital project.”

The project is designed to ease serious congestion caused by the under-capacity of the two existing immersed tube crossings of the Chesapeake Bay shipping channel underpass, the first built in the early 1950s and the second in the early 1970s.

The project has passed through several phases of development including the submission of various unsolicited proposal to provide solutions of different configurations and commercial arrangements, as reported by TunnelTalk in previous articles.

With a contract award for the current procurement programme anticipated in early 2019, the project completion date is targeted for 2024, a date that will not arrive soon enough for users of the current under-capacity crossing.

References

- Hampton Roads crossing plans revitalized in USA – TunnelTalk, July 2017

- EPBM for Thimble Shoals parallel tunnel – TunnelTalk, August 2017

Hampton Roads crossing plans revitalized in USA 20 Jul 2017

A request for qualifiers (RFQs) for construction of the US$3.3 billion Hampton Roads Bridge-Tunnel expansion project is scheduled for Fall this year (2017) following issue of a formal record of decision (ROD) by the US Federal Highways Authority.

From a number of proposals, Corridors 8 and 9 of the Alternative A are selected as preferred options to relieve traffic congestion in and around the Hampton-Norfolk-Portsmouth triangle and in the state of Virginia (Fig 1).

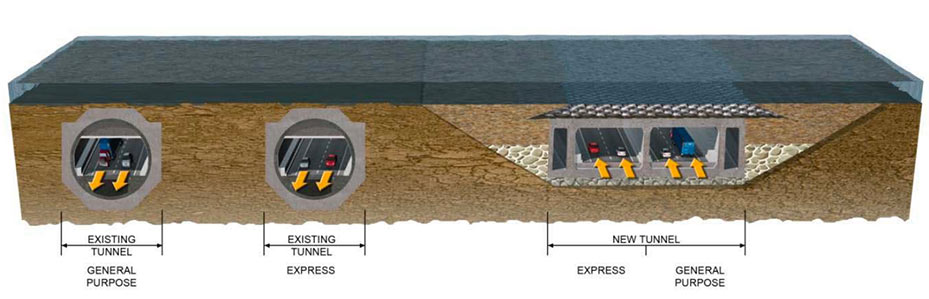

As part of the project, the Interstate I-64 highway across the mouth of Chesapeake Bay between Hampton and Norfolk will be widened from four to six lanes with a third trestle bridge increasing the crossing from the Hampton side to North Island and from the Norfolk side to South Island, and a new 7,500ft-long (2.2km) tunnel between enlarged North and South Islands to provide relief for the existing pair of two-lane immersed tube tunnels.

According to a national study carried out in 2011, the existing two-lane crossings are among the top 100 most congested highways in the USA. When the first two-lane immersed tube tunnel was opened to traffic in November 1957, an average 6,000 vehicles used the crossing each day. A second tube added in 1976 increased design capacity to 77,000 vehicles per day, but today the bridge-tunnel crossing is handling traffic volumes of up to 100,000 vehicles a day.

A Virginia Department of Transportation (VDoT) spokesman declined to answer questions at this stage of the project, but confirmed to TunnelTalk that the planned new project will provide three extra traffic lanes. This is one lane less than originally proposed in the 2008 feasibility study.

The decision to proceed with the project brings to a conclusion a period of 16 years that has seen a 2001 Federal ROD in support of a reduced-scope project, numerous alignment and technical studies, a formal crossing study in 2008, three unsolicited construction proposals in 2010/11, and the termination of an earlier construction procurement process in 2014.

The first unsolicited conceptual proposal was submitted to the VDoT in September 2010 by the Skanska/ Kiewit/ Weeks Marine (Hampton Roads Crossings) JV, with Parsons Brinckerhoff as lead designer. After accepting the proposal in October 2010, VDoT called for competing proposals and in February 2011, a second conceptual proposal was received from the Cintra Infraestructuras SA/ Ferrovial Agroman JV. A third proposal received from the ACS/ Dragados USA/ Flatiron JV (Hampton Roads Mobility Group), with Moffatt & Nicol as lead design engineer, and Arcadis as tunnel design engineer, proposed to double tunnel capacity by adding a four-lane westbound immersed tube tunnel, and dedicating the existing tubes to eastbound traffic only (Fig 2). This would also have had the benefit of facilitating the westbound movement of overheight trucks across the Bridge-Tunnel. Such vehicles are currently unable to use the crossing.

In 2014 VDoT wrote to all three teams to cancel the project based on legislation to assess “multiple opportunities for transportation improvements throughout the Hampton Roads region”.

Following amendments to the original environmental impact study, and issue of a revised ROD to supersede the original one of 2001, owner VDoT hosted a contractor’s conference in April this year (2017) to test interest in the project. This atracted 271 delegates representing top American and international contractors and engineering design consultancies. Of these, 16 major US and international contractors and financiers responded to the owner’s request for information (RFI) and held discussions with VDoT concerning their construction procurement preferences.

The contractors that responded to the RFI included the three teams that made unsolicited proposals in 2010/11 – ACS/Dragados, Cintra/Ferrovial Agroman, and Skanska/Kiewit/Weeks Marine – and companies Bechtel, Condotte America, FCC Construction, Fluor, John Laing, Lane Construction, Macquarie, Transurban and Vinci.

One of the most interesting responses to the RFI comes from the Cintra/Ferrovial Agroman JV, which suggested that a 4+4 lane design, rather than the current 3+3 lane proposal, might offer better long-term value. To this end, its proposal includes an option to construct two new 4-lane tunnels and decommission of the existing and aging, 2 x 2-lane tunnels which both feature below-standard vertical clearances and narrow emergency lanes.

Although no decision has yet been made on the method of tunnel construction, it is likely to be an immersed tube tunnel to match the existing tubes, which are circular profile steel immersed tunnels (see below). A feasibility study carried out in 2008 concluded that it was not likely that a TBM could be used to excavate the new tunnel on account of the “looseness” of the geology in the upper layers of a bored tunnel alignment. If a TBM were to be used, the new tunnel would have to be aligned deeper to provide adequate cover and would result in a “significantly longer tunnel”.

Given these geological limitations, the 2008 study recommended a concrete rectangular-profile immersed tunnel running 250ft outside the alignment of the existing eastbound tunnel, a solution which would require the widening of the existing man-made North and South Islands. The risk of damage to the two existing tunnels by running the new tunnel between them was considered too high.

According to VDoT’s current project schedule, the final decision between the design-build procurement method, or the concessionary design-build-finance-operate-maintain or design-build-operate-maintain (DBOM) methods, will be made later in this Summer. A construction shortlist is due to be announced in Spring next year (2018), followed by a request for proposals in Summer 2018 ahead of a planned contract award in Summer 2019. Construction is anticipated to take five years, with the expanded Bridge-Tunnel opening in 2024.

This will be the third major highway tunnel project in Virginia in recent years joining the US$1.46 billion 1,700m long immersed tube Midtown Tunnel across of the Elizabeth River between Norfolk and Portsmouth, which opened fully to traffic in August 2016 to relieve the over-capacity Downtown Tunnels, and the 1,740m long parallel Thimble Shoals TBM tunnel for the Chesapeake Bay Bridge-Tunnel crossing awarded to the Dragados/Schiavone JV in July 2016 for US$755 million.

Original immersed tunnel construction

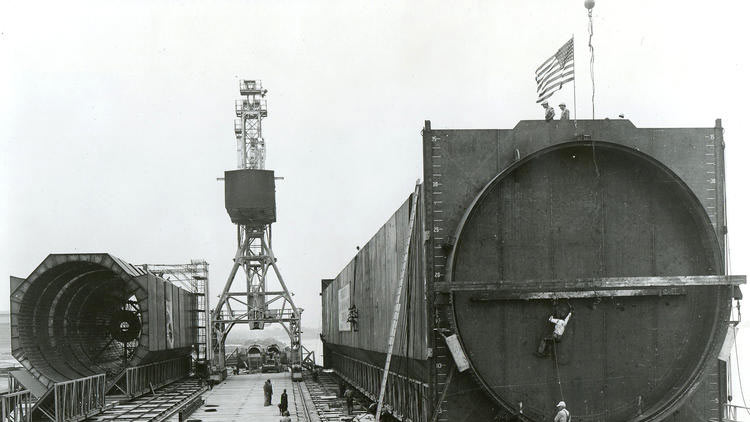

The original Hampton Roads tunnel 60 years ago, was constructed at a cost of US$44 and comprised 23 circular profile steel skinned elements for a total length of 6,859ft (2km) and included two 90ft cut-and-cover box sections on each of the man-made North and South Islands. It was the first construction in the world of a submerged tunnel between man-made islands.

The tunnel roadway descends on a 4% grade from the north trestle and ascends on a 0.5% grade of under the main channel before ascending at 4% to the south trestle. The width of the two-lane roadway is 23ft between curbs with a minimum vertical clearance of 14ft, which is insufficient to accommodate modern-day heavy goods vehicles.

The elements, which weigh 600 ton each, were fabricated at Port Deposit, Maryland, and barged to the jobsite via the Susquahana River which flows into Chesapeake Bay. Each 350ft long element has a double shell with an outer 37ft diameter octagonal concrete shell around an inner circular steel shell of 33ft in diameter. Partial filling of concrete pumped into the void between the shells was the method used to sink the elements into position.

Once installed in their final position using hydraulic jacks, the elements were bolted together and the remaining space between the shells filled to the complete 1,500 ton of concrete. A solid ring of concrete was poured around each joint and as the steel bulkheads were progressively cut through, the joints of the sleet inner shells were welded from the inside and faced with an inner ring of concrete. Once in the trench on the river bed the tube was covered with 5ft of sand.

A second immersed tube, which doubled capacity to four lanes, was constructed at a cost of US$95 million in the early 1970s and opened to traffic on 1 November 1976.

References

- Thimble Shoals tunnel contract award – TunnelTalk, July 2016

- Sinking the concrete elements at Midtown – TunnelTalk, December 2014

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.