London Main Ring inspection and maintenance 29 Oct 2020

Inspection and maintenance work on a 35km section of the 80km London Water Ring Main and relining of 1.9km of inlet and outlet tunnels at the Walton-on-Thames QEII Reservoir is part of a £22 million programme of inspections and repair work awarded to UK contractor Barhale.

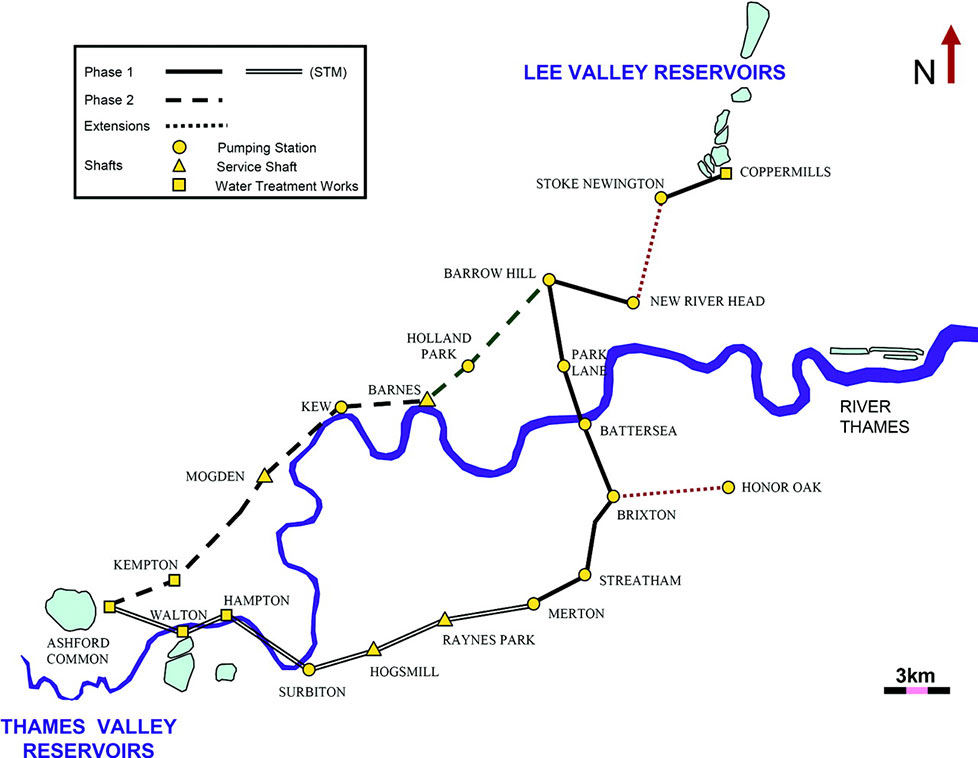

Depending on the criticality of the asset, regular inspection of the Ring Main is required under the provisions of the Reservoir Act 1975, according to Phil Cull, Southern Region Director at Barhale. The work involves the isolation and draining of the tunnels to allow access for a line-and-level survey, as well as any required repair or replacement of pressurised assets from within the access shafts or tunnels. Sections of the Main Ring between Battersea and Park Lane, New River Head and Barrow Hill, and Hogs Mill to Raynes Park are among those to be inspected, with work on the Brixton to Honour Wood section already complete.

Barhale is also refurbishing one high integrity gate valve at New River Head, and three at Barrow Hill, while all existing white caps – the lifting eye sockets for each plate – on the 14.4km stretch of the Ring Main between Ashford A4 and Kew via the Kempton shaft, and on the 12.7km stretch between the shafts at Kew and Barrow Hill, via Barnes and Holland Park, are being replaced. In total 220,000 new white caps will be installed.

In addition to work on the Main Ring, 12 raw water tunnels of various diameters and constructions, including brickwork, cast iron, steel and wedge block, totalling 9km in length, will be inspected. This will again require isolation of the tunnels, at both upstream and downstream ends, and draining using temporary drop-in pumps. Necessary repairs will be made and any debris, such as silt and zebra mussels, will be removed before a final walk-through with representatives of Thames Water.

At the QEII Reservoir, the 1.1km inlet and 0.8km outlet tunnels will be fitted with an in-situ concrete lining. Both 2.5m i.d. alignments are lined currently with unbolted reinforced concrete wedge block dating back to the reservoir’s original construction in the 1960s.

Works at QEII Reservoir will require the demolition of an administration block and laboratories to make space for the construction of a temporary 9m dia. jacked caisson. Barhale has completed similar relinings, at the Queen Mother, Wraysbury, and Datchet reservoirs.

The award of the contract to Barhale builds on more than three decades of work by the company for Thames Water. Since 2000, it has been involved in every asset management period, AMP, of capital works, up to and including the most recent, AMP7.

“We have been engaged by Thames Water for more than 30 years, building new infrastructure and delivering a wide range of asset repairs, renewal, and replacement, both above and below ground,” said Phil Cull. “Our self-delivery model and directly-employed workforce ensures we deliver safe and reliable outcomes.”

As part of the current AMP6 work, the company is refurbishing the Ring Main shaft at Kempton Park, the 16th such refurbishment it has carried out and the 19th of the 22 shafts on the Ring Main that Barhale has worked on. “We bring a level of understanding and experience to works on the water supply for the capital,” said Phil Cull.

In addition to work on the Ring Main and QEII Reservoir, Barhale has been selected for the geographic infrastructure framework programme that focuses on the delivery of the water and wastewater infrastructure programme in north London. Work will include the installation and replacement of new trunk and rising mains, pressure management, further tunnel inspection work, sewer rehabilitation, pumping station refurbishment, and gravity solutions to maintain asset health and allow for growth.

Barhale is also involved in construction of the London Tideway CSO interceptor project for Thames Water, working across various sites.

At Victoria Embankment Foreshore, part of the central contract, the company is working with the Ferrovial-Laing O'Rourke JV, completing shaft excavation and primary lining, and now in the process of secondary lining. The site will connect an existing CSO to the main Tideway alignment. In west London, at Barn Elms, the company is working with the BAM Nuttall-Morgan Sindall-Balfour Beattie JV, and has recently completed a 215m pipe jack to drive a 2.5m dia. connection tunnel to the main alignment.

Meanwhile, at the eastern end of the project at Beckton, Barhale is working with a Costain-Atkins-Black & Veatch JV to install a 45m x 2.8m dia. steel pipeline to join the existing Lee Tunnel to a new storm tunnel, as part of the integration work into the Tideway system.

References

- Second of four main Tideway drives breakthroughs – TunnelTalk, October 2020

- London Water Ring Main feeder – TunnelTalk, December 1992

- Geared up for London Ring Main drive and beyond – TunnelTalk, December 2020

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.