River Humber crossing fitted with gas pipeline 17 Jul 2020

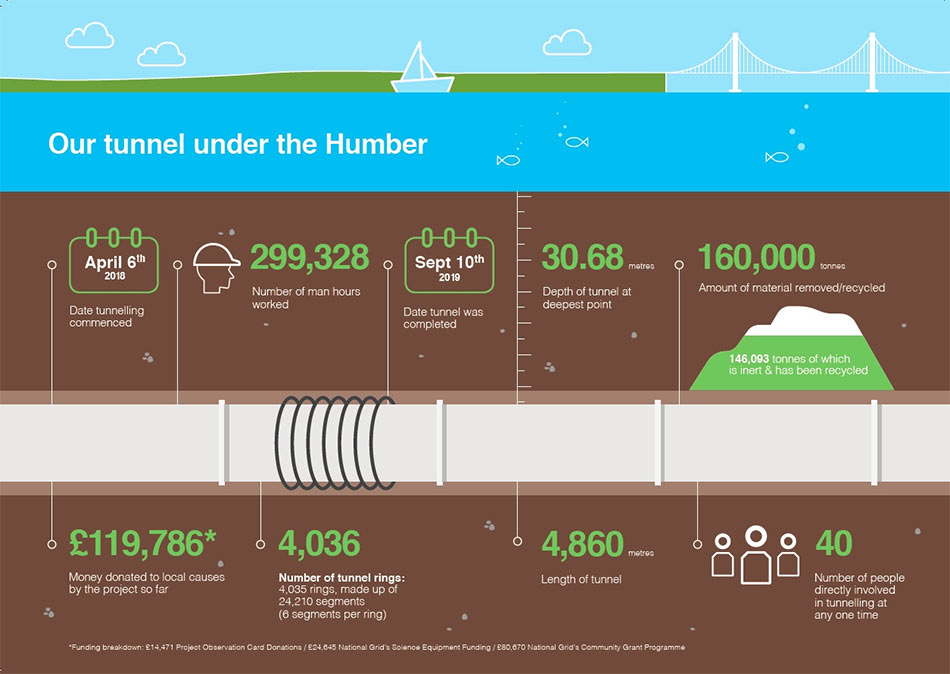

Excavation of a 5km long x 3.65m i.d. host tunnel at 30m under the River Humber, has been fitted with its section of a vital gas transmission pipeline for the UK. JV partners Skanska, A.Hak and Porr, used a 4.4m diameter Herrenknecht TBM to excavate the concrete segmentally lined tunnel which will now host the new gas pipeline. The tunnel replaces a trench-laid gas pipe on the river bed that had become exposed and vulnerable. When gas begins to flow through the pipeline, it will help ensure reliable and resilient transmission of up to 25% of gas supply in Britain.

5km of 1.22m diameter pipeline laid out ready for installation

Inserting the 1.22m diameter steel gas pipeline used 750 tonne hydraulic thrust supplied by two Herrenknecht pipe thrusting machines. From the working portal of the tunnel on the Goxhill side of the river the machines pushed eight 620m long x 850 tonne sections of pipe on rollers into the new tunnel. The pipes were methodically pushed at around 1m/min into the tunnel which had been flooded with 50,000m3 of pure treated water to aid installation and provide the backfill host medium for the pipeline through its design life.

On inserting one pipe section, the next was moved into position and welded to the one in front. After starting with the first string on 23 June, the push continued until all 5km of pipeline was fully installed on 9 July, claiming the accolade of the longest hydraulically inserted pipeline in the world.

“Completing the installation of the pipeline under the Humber is a major achievement for both the project team and partners,” said Steve Ellison, Senior Project Manager, Capital Delivery, for National Grid. “We will now begin work to connect the pipeline to the network, ready for gas to begin flowing towards the end of the year.”

“This project shows what can be achieved when you put three expert companies together and create a highly collaborative environment,” said Gregor Craig, CEO of Skanska. “Our client, National Grid, set us a considerable challenge and our team has risen to it brilliantly. While we still have a way to go, it is clear that we are on track to provide National Grid with the critical national infrastructure solution that they were seeking.”

References

- River Humber gas pipeline breaks through – TunnelTalk, September 2019

- Vital estuary crossing to keep UK gas flowing – TunnelTalk, January 2014

- Contract award for 5km Humber tunnel – TunnelTalk, April 2016

River Humber gas pipeline breaks through 12 Sep 2019

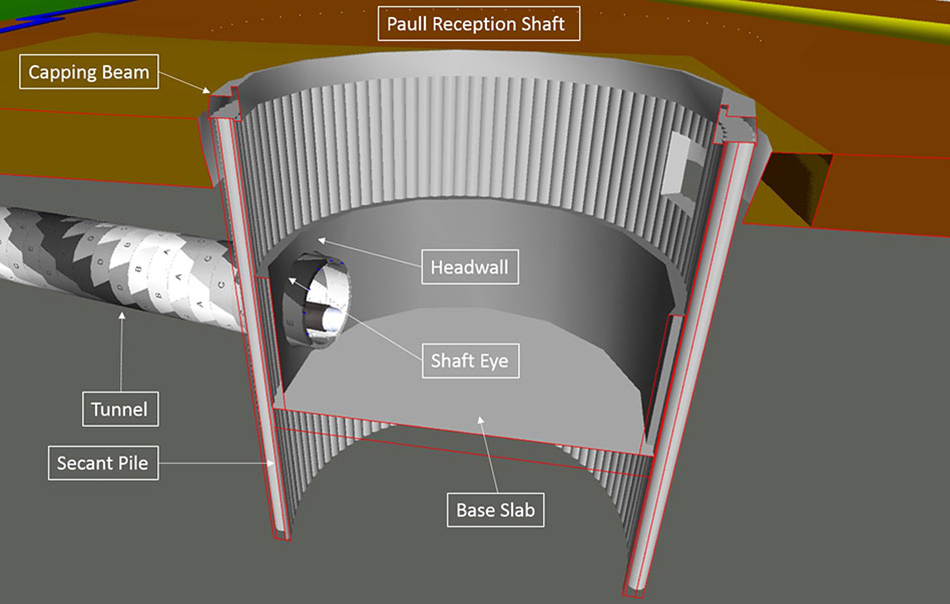

National Grid and Skanska/PORR/A Hak JV celebrated the breakthrough on a 5km tunnel to house a replacement gas pipeline 30m beneath the River Humber, when the 3.65m i.d. TBM completed excavation on 10 September 2019. The breakthrough into the specially constructed shaft at Paull on the north bank of the river marks the end of an 18 month drive from Goxhill on the south side, and the start of the next phase, during which the project claims that the longest hydraulically inserted pipeline in the world will be installed.

“Completing the tunnel, which is the first beneath the Humber, is a major milestone for the project team and our partners," said Steve Ellison, Lead Project Manager, Capital Delivery, for National Grid. "Over the next few weeks we will be dismantling the TBM and lifting it out, ready to be transported back to Germany where as much as possible will be refurbished for its next job. The next steps for us here under the Humber involve clearing the pipes, cables and ancillary equipment that has been servicing the TBM and preparing for pipeline installation early next year.”

References

- Contract award for 5km Humber tunnel – TunnelTalk, April 2016

- Breakthrough imminent for Humber pipeline – TunnelTalk, September 2019

Breakthrough imminent for Humber pipeline 05 Sep 2019

National Grid in the UK is expecting to complete the almost 5km excavation under the River Humber, as its TBM reaches the last metres of its route 35m below the river bed to house a replacement gas pipeline.

The 4.4m diameter Herrenknecht TBM, designed for the project, is proceeding slowly for the last section due to varied geological conditions but at the time of publishing was 55m from expected to break through The 5km long x 3.65m diameter tunnel will house a vital new gas pipeline to replace the existing one crossing the River Humber in a trench just below the river bed. Over time, tidal patterns have eroded the river bed, risking its exposure. Due to its importance, National Grid is constructing a new pipeline below the Humber from installations at Goxhill and Paull as a long-term replacement.

National Grid awarded the design-build contract for the new high pressure gas pipeline to the Skanska/PORR/A Hak JV in May 2016, and tunnelling work began in April 2018. The pipeline connects an import location for gas at Easington, on the East Yorkshire coast, to the wider national network, and will carry about 25% of the gas Britain needs, supplying millions of homes and businesses across the east of England and beyond.

It has taken the Herrenknecht TBM 18 months to advance the heading from Goxhill on the south side of the river to Paull on the north bank. The 160m machine has excavated about 160,000t of material – mostly chalk, which has graded and reprocessed at the Goxhill slurry treatment plant for use to restore a former quarry nearby Humberside Airport.

Once the breakthrough is achieved, the TBM will be retrieved at the Paull reception shaft and returned to Herrenknecht in Germany, where components will be renewed and refurbished.

In Spring 2020, work will begin on site to push eight 610m long x 850t sections of pipe on rollers into the new tunnel from the Goxhill side. Two hydraulic thrust machines will push the pipes at about 1m/min into the tunnel, which will be flooded with water to aid installation. When one pipe section has been installed, the next will be moved into position, welded to the one in front, and the push will continue until all 5km of pipeline is installed beneath the river. When complete, it will be claimed as the longest hydraulically inserted pipeline in the world.

References

- Contract award for 5km Humber tunnel – TunnelTalk, April 2016

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.