Tenders invited for 16.4m o.d. Lower Thames Crossing 11 Nov 2020

Tendering for the design-build contract for one of the largest-diameter bored highway tunnels in the world has begun. The 16.4m o.d. x 4.3km twin tube Lower Thames Crossing will be the longest road tunnel in the UK and will nearly double capacity across the Thames east of London, relieving the heavily-congested M25 tunnel and bridge crossing at Dartford. The tunnel will form part of a new 23km highway between the existing A2/M2 junction in the south and the A13/A1089 and M25 junction in the north (Fig 1). It will be delivered in three main works packages for the tunnel crossing, and the surface road works to the north and south. Estimated cost of the tunnels package is £2 billion out of a total estimated cost of between £6.4 billion and £8.2 billion.

Initial consultation by project owner, Highways England, on the route began in 2016 with the UK Department for Transport choosing its preferred option in April 2017. A period of statutory, supplementary and design refinement consultations took place between October 2018 and August 2020. The official planning application, known as a Development Consent Order (DCO) was then submitted in October 2020 to the UK Planning Inspectorate which is now reviewing the documentation before approving the application for consideration. A decision on the DCO and the final business case is expected in early 2022.

“We have a clear solution set out in the DCO submission but we also recognise there are a number of areas of opportunity to refine and improve the project in its scheduling, cost savings or carbon savings aspects for example,” said Keith Bowers, Tunnels and Systems Director for the Lower Thames Crossing. “As we move into procurement, we are keen to talk to prospective suppliers to see what more can be achieved,” Bowers said on a recent video call with TunnelTalk and with Ben Green, Head of Ground Investigation Delivery for the project.

Technical support through the development and construction phases of the Lower Thames Crossing is being provided to Highways England by the LTC CASCADE joint venture between COWI, CH2M, now part of Jacobs, and Arcadis. Awarded the contract in 2016, the role has included the detailed environmental surveys, traffic modelling, economic analysis, planning and design of the preferred route, full environmental impact assessments, engagement and consultation activities and preparation of the DCO application.

In a more unusual approach to the procurement process, the design-build contract is designed to incorporate all foreseeable delivery risks within the target budget. “The aim is to set up an environment where all parties are working together to deliver within the budget, rather than wrestling each other over the usual issues,” said Bowers. The contract procurement process is expected to run until contract award in mid-2022. An invitation to participate in the competitive dialogue procurement process is planned to be issued to at least three pre-qualified design-build groups in Spring 2021 with a formal tender submission expected in late 2021.

“This is a globally significant project,” added Bowers, “and we are excited to hear from prospective bidders, who will bring their experiences to the project. We are confident in our basic proposition, but I am sure there will be some very interesting discussions over how we ensure the best result.”

Ground investigation campaign

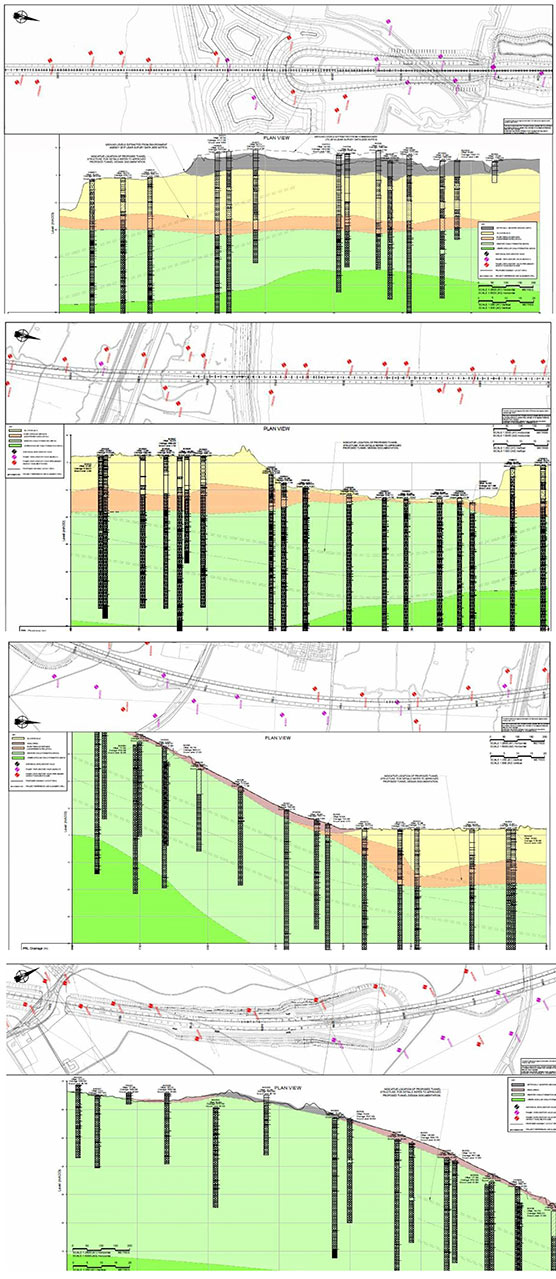

Leading up to the submission of the DCO, there had already been an extensive programme of ground investigation. The work was carried out by geotechnical investigation contractor Perfect Circle, starting in 2017. In addition to extensive geophysics, the work included investigation of unexploded ordinance (UXO) left as a result of WWII bombings, ultra-high resolution seismic studies, bathymetry and Tromino surveys, as well as laser scanning of flints, pumping tests, geomorphology studies, and laser imaging, detection and ranging (LIDAR) surveys. More than 10km of core samples were collected over the course of the ground investigations, requiring the project to rent dedicated warehouse space for the samples.

“We learned the lesson from other recent major tunnelling projects around London, including the Silvertown Thames River road crossing, the HS2 and Crossrail rail projects and the Tideway supersewer project, which follows the alignment of the Thames River, that the more ground investigation and the earlier it is done, the better the outcome and the prospects for success,” said Green. “As a result, Highways England has invested heavily in ground investigation at this stage, completing three phases over three years.”

Fig 3. North portal located alongside a landfill for muck disposal and an operating open cut flyash mine

The first phase was a fairly limited study of 40 boreholes, beginning after the preferred route was announced, and concentrated on the areas around the two portals. Phase two took place in Summer 2019 and was a more substantial programme of work, targeting 550 locations along the complete twin tube alignment, including the use of two jack-up barges on the Thames to collect 26 core samples from the river bed. The investigations focused principally on supporting the planning submission and the environmental impact statement, to identify any areas of contamination and environmental sensitivity, as well as consider some of the key constructability aspects of the project.

The final phase included more than 550 further locations and was designed to be “the equivalent of a contractor’s ground investigation, in that it is sufficient to allow the main works contractors on the three works packages to start detailed design as soon as the contract is awarded,” explained Green. To support that, the project management team engaged with prospective main works contractors on the scale and scope of the ground investigations. “It was a highly intensive campaign during Summer 2020 with 50 rigs working at the peak of activities.”

The extensive ground investigation has also allowed early mitigation planning on environmentally sensitive areas, which includes wetlands protected under the Ramsar Convention on Wetlands as of international importance, while also helping to ease concerns of local residents.

Large diameter twin bores

The exact length of the expected 4km-long twin tubes will be determined by the contractor during detailed design. The number of cross passages will also be determined during detailed design but is likely to be 27 based on the required 150m spacings. In addition to the bored tunnel, short elements of cut-and-cover create the portals at either end of the drives.

The large 16.4m o.d. of the tunnels is determined by the requirement to house a three-lane 110km per hour (70mph) highway in each tube. “There are only two projects to-date that have used larger diameter TBMs than those we anticipate will be used on the Lower Thames Crossing,” said Bowers, “although the global trend is for larger diameter machines.” A 17.48m dia. Hitachi Zosen machine was used on the Alaskan Way highway replacement tunnel in Seattle, USA, and a 17.6m dia. Herrenknecht Mixshield was used on the Tuen Mun Chek-Lap Kok subsea highway link in Hong Kong.

The twin tubes are expected to advance from the north portal (Fig 2) with the tunnel contract including 1km of surface road at the northern end, leading up to the open-cut portal structure. “There is relatively good access for the TBMs to the north portal via the Thames River Port of Tilbury to the west,” explained Bowers. It is also a good position for muck disposal with the adjacent landfill currently receiving muck from the Tideway project and likely also to receive the muck from the Silvertown crossing between Silvertown and the Greenwich Peninsula. “Given those factors it made sense to drive from the north portal.”

Despite these benefits, it is an “interesting site to plan major infrastructure work,” continued Bowers. In addition to the landfill, the site includes an active opencut mining site, where power plant fly ash is being recovered (Fig 3). This results in a site where the ground level is “going up and down around us,” said Bowers. There is also a closed landfill site known to contain a range of hazardous materials, which means the Lower Thames Crossing design work “must avoid the risk of contaminating ground water”.

From the north end, the geology comprises made ground over alluvium, followed by a layer of gravels and Seaford and Lewis Nodular Chalks (Fig 4). It is through these chalk deposits that the majority of the alignment lies, making slurry machines the more likely choice, although the precise specification will lie with the contractor.

“With excavation starting from a cut, there will be a variety of materials to deal with, some by cut-and-cover processes and others by the TBMs,” said Bowers. Although it will be down to the contractor how to navigate these conditions, “we anticipate the TBM will start with the face within the alluvium and then traverse through the gravels. These mixed face conditions will pose some interesting challenges when it comes to launching the large-diameter TBMs.” It is also inevitable that a number of cross passages will intersect the alluvium and gravels, creating additional construction challenges.

As a result, “we anticipate that there will be a substantial level of ground treatment required in this area to ensure we have appropriately competent ground for construction of the various elements of the portals and into which to launch the machines,” said Bowers.

As the bores reach the river crossing, the TBMs will be operating in a full face of chalk. At the deepest point of 55m below high-water level, “we have the potential for 5 bar to 5.5 bar of water pressure, as well as the presence of flints, which will be major considerations when deciding on the type of machine,” continued Bowers. Cross passage construction will also be impacted by the water pressures and the exact methodology for their excavation will be determined by the contractor. The project team is however “confident in the ability to form the cross passages.”

As the TBMs move beyond the river on the south side, the tunnel will pass underneath an area of low-lying land that houses a Metropolitan Police training facility, a local railway, and the protected wetlands. At this point, the alignment cuts through the surface of the chalk and back into the gravels, raising again the challenges of mixed face conditions and relatively low cover. “The priority in this area will be to protect the wetlands from any environmental disturbance,” said Bowers. “We will be very interested in the control methodology of the tunnelling works suggested by the contractor through this area.”

The profile then returns to the chalk as the topography begins to rise, climbing to the south portal. Most of the work will be through saturated ground but moves above the water table as it approaches the south portal. This will pose a different challenge for TBM operation, noted Bowers, but means the south portal structure will not require as heavy a retaining structure as at the north portal.

When complete, the tunnels will have an internal diameter of 15m (Fig 5). “The profile allows a lot of space under the road deck,” continued Bowers, “which means we can place a lot of the equipment and systems that might usually be placed in the cross passages in the invert below the road decks. These will include pumps, cables, transformers and other operating systems.” This provides a number of benefits, including the ability to maintain longitudinal maintenance access during operation, without the need to close lanes to traffic. It also reduces the necessary size of the cross passages to 5m diameter.

Included as part of the tunnels contract are the design and installation of the finishing and operating systems. “To ensure we achieve high availability of the under-river crossing in operation, we have developed a systems engineering approach within the project that specifies the performance that is required. This is integrated through the design of all of the systems across the wider network to ensure resiliency to various incidents and events,” concluded Bowers.

Ahead of that, the project team is advancing the project towards inviting three design-build groups to join the process in Spring 2021, a formal tender submission in late 2021 and award of contract in mid-2022. The Lower Thames Crossing is expected to open to traffic between 2027 and 2028.

References

- TBMs specified for critical Thames highway crossing – TunnelTalk, January 2016

- Silvertown PPP contract signed in London – TunnelTalk, December 2019

- Second of four main Tideway drives breakthrough – TunnelTalk, October 2020

- Tracking mega TBMs of the world – TunnelTalk, September 2020

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.