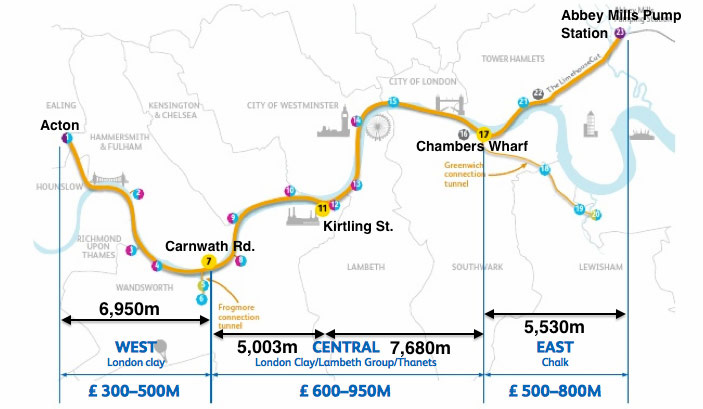

With two TBM drives complete and three underway, excavation of the 30.7km Tideway main CSO interceptor and its connecting tunnels is more than 13.85km complete. First to breakthrough, in late October 2019, was the refurbished Lovat TBM on the 500m southerly Dormay Street to King George’s Park section of the Frogmore connector, part of the West Contract. This was followed by one of two 8.8m diameter NFM EPBMs working on the Central Contract for the Ferrovial - Laing O’Rourke FLO JV which finished its 5km x 8.8m o.d. (7.2m i.d.) bore on the westward Kirtling Street to Carnwath Road section in November 2019 (Fig 1).

The second NFM EPBM on the Central Contracgt is 4.4km into its 8.8m o.d. (7.2m i.d.) x 7.7km drive, heading eastward at a rate of 20m-25m/day from the Kirtling Street launch shaft to the reception shaft at Chambers Wharf. Launched in March 2019, the machine recently reached Blackfriars Bridge Foreshore, where it will undergo scheduled maintenance ahead of its final drive through to Chambers Wharf. It is expected to complete excavation through the mixed geology under Westminster and the City of London in late 2020.

The shield of the first NFM machine to finish its drive at the Carnwath Road shaft has been turned aside and will be buried after being stripped of its parts. The rear gantries of the TBM are being stripped and removed back through the drive and via the Kirtling Street launch shaft. The connection of the 5km reach to the Carnwath Road shaft will be excavated by hand and finished with a secondary sprayed-concrete lining.This approach was required because the Carnwath Road shaft is doubling as the launch shaft for one of the West Contract TBMs. According to Tideway, the presence of the support equipment associated with West Contract TBM made the off-line end of the Central Contract TBM and manual excavation of the final section of the drive “the most efficient solution”. All other Tideway TBMs will break through into their reception shafts.

On the West Contract, the BAM Nuttall-Morgan Sindall-Balfour Beatty BAM JV TBM main alignment between Carnwath Road and Acton Storm Tanks is more than 3.5km into the near 7km drive. Excavating west from the launch shaft at Carnwath Road, primarily through London Clay and at a rate of 20m-25m/day, the Herrenknecht EPBM is expected to breakthrough in late 2020 or early 2021.

Excavation of the 1.1km x 2.5m i.d. Frogmore connector for the contract also began again at the end of January 2020, when the refurbished Lovat EPBM was relaunched from the Dormay Street location, after retrieval from the King George’s Park shaft in December 2019 (Fig 1).

The 3.3m Lovat EPBM was built in 1994 and completed five projects totalling 16.6km between 1994 and 2007 before overhaul and adaptation for the Frogmore drives.

The 3.3m Lovat EPBM was built in 1994 and completed five projects totalling 16.6km between 1994 and 2007 before overhaul and adaptation for the Frogmore drives.

Excavation on the East Contract by the Constain-Vinci-Bachy Soletanche CVB JV using two Herrenknecht slurry TBMs is expected to begin this year to complete the 5.5km of the main 7.2m i.d. Tideway alignment between Chamber’s Wharf and Abbey Mills pumping station, as well as the 5.5m i.d. x 4.6km long Greenwich connector tunnel.

Geology along the route comprises Seaford Chalk with external water pressures of up 5 bar. The first TBM arrived onsite last year and is expected to be launched in early 2020 from the Greenwich Road pumping station shaft on the Greenwich connector drive to Chambers Wharf, according to the most recent interim report. Delivery of the second TBM to excavate the main alignment west between Chambers Wharf and Abbey Mills pumping station (Fig 1) is to follow later this year (2020). From Abbey Mills, Tideway joins the existing Lee Tunnel, which carries flows to the Beckton treatment works.

Secondary lining of the 60m deep Chambers Wharf shaft was recently completed. The slipform construction used more than 4000m3 of concrete produced from an onsite batching plant, supplied with aggregate via barge to reduce construction related traffic on local congested roads.

In addition to the main alignment, Tideway includes 22 shafts and nine short connection tunnels. In November 2019, pipejacking machines arrived at two Tideway sites to excavate two of the short connection tunnels. The first of these machines is boring a 200m alignment linking the west Putney storm relief CSO to the main Tideway alignment. A second recently completed a 134m drive to link the Putney Bridge CSO to Tideway.

Another short connector will intercept flows from the Hammersmith pumping station, where an average of 2 million m3 of untreated sewage is discharged into the Thames annually.

The Hammersmith project included construction of an interception chamber, connection culvert, a 35m deep x 11m i.d. drop shaft and a connection tunnel to the main alignment (Fig 2). The drop shaft and the 300m long connector, comprising a 48.1m long x 5.1m i.d. dearation chamber and 250m of 4m i.d. excavation, were advanced by the SCL sprayed concrete lining method through London Clay and finished with an insitu concrete secondary lining. The connector runs out to the centre of the Thames, passing under a river wall, two blocks of luxury apartments and 20m below the river (Fig 2).

Initial design called for a waterproofing membrane to meet Tideway-defined water ingress/egress specifications of 0.1 litres/m2/day on average or 0.2 litres/m2/day over any 10m section. This was later replaced by the design team with a Xypex crystallising agent incorporated into the primary lining which improved permeability and watertightness of the sprayed concrete lining. A programme of preconstruction testing demonstrated that a Xypex admixture dosage of 5kg/m3 satisfied the design performance of the alternative.

Following completion of the primary lining, no water ingress was measured in the shaft against a maximum allowable ingress of 106 litres, given a surface area of 1,060m2. There were no joints with visible movement of water. In the tunnel, only 9 litres of water ingress was measured against allowable ingress of 434 litres, given a surface area of 4,341m2. Any damp spots recorded were injected with resin grout, after which the tunnel was signed off as watertight.

The secondary insitu concrete lining was cast using a PLC-driven 6m long formwork with automatic spud bars. Supplied by Kern Tunneltechnik, this was the first formwork to have an integrated PLC, according to the project team, allowing semi-automatic and fully-automatic operation.

As part of the West Contact, the Hammersmith connector was featured in a presentation by Ed Batty of BAM Nuttel and Peter Coppenhall of Morgan Sindall Engineering Solutions at a meeting of the British Tunnelling Society.

As of September 2019, capitalised expenditure on the projected totalled £2.218 billion with costs on track to remain in line with the revised £3.8 billion estimate stated in the project’s 2018/2019 Annual Report. The total cost was previously raised by £300 million, following early challenges at the Blackfriars and Kind Edward Memorial Park sites.

Despite the complexity of the project, 83% of the shafts and 12.5km of the main tunnel is now complete. Tideway reports that it is making good progress towards its goal of scheduled finish in 2024.

|

|

|

|

|