HS2 prepares TBMs, shortlists systems and M&E bids 04 Feb 2021

The first three of ten main line TBMs are preparing to launch on the first phase of the high-speed rail link between Birmingham and London in the UK. Two will drive under the Chiltern Hills and are expected to begin excavations for contractor Align JV in Spring 2021. A third machine will drive under ancient woodland near the village of Long Itchington in Warwickshire with contractor Balfour Beatty and Vinci JV, BBV, expecting to start excavations in Summer 2021.

As its contractors prepare to launch the TBMs, project owner HS2 Ltd announced the shortlists for track systems and for tunnel and lineside M&E contracts. Worth almost £2.5 billion, the contracts cover HS2 Phase 1 and the Phase 2a extension from Birmingham to Crewe (Fig 1).

Preparing the TBMs

Components of the two 10.26m diameter variable density machines for the 16km x 9.1 i.d. Chiltern drives began arriving in the UK from the Herrenknecht factory in Schwanau in December 2020.

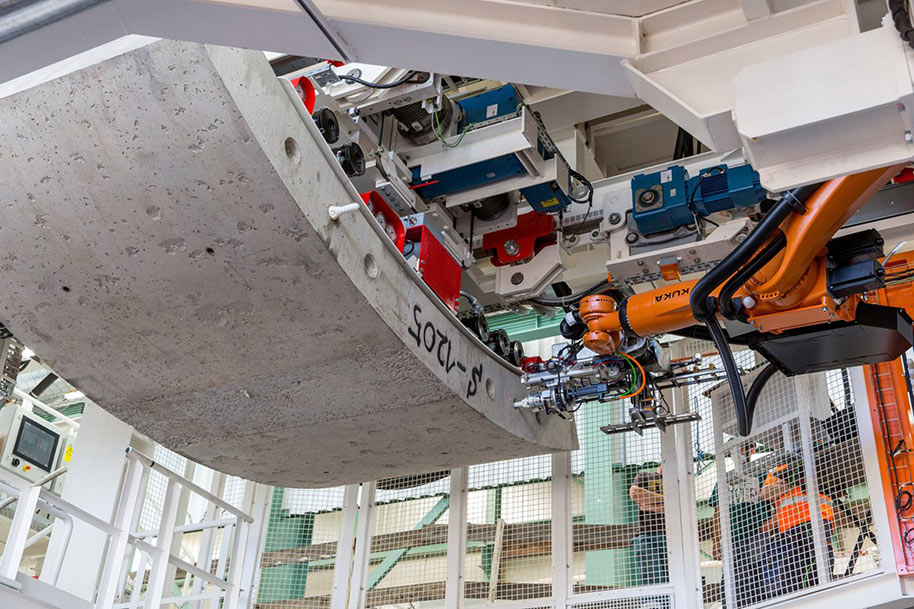

Designed for the mix of chalk and flints under the Chiltern Hills, the machines also feature a range of innovative technologies, including a robot to automatically remove the wood spacers, which are placed between lining segments when stacked and transported, and insert the connecting dowels, as the segments arrive in the TBM handling area. Known as Krokodyl, the robot is the first of its kind, according to HS2 Ltd and works in a similar manner to the robotic arms used on car assembly lines.

“The use of the Krokodyl robot is an example of the sort of innovations we are pleased to see implemented on the project to remove personnel from harm’s way,” said Eddie Jones, HS2 Ltd Head of Tunnelling. Each TBM will be run by a crew of 17 with another 30 in each shift on the surface and in the tunnel behind the machine.

The segments in each 2m wide x 400mm thick ring of precast concrete lining will weigh up to 8.5 tonne with seven per ring and 112,000 required to complete both 16km long tubes. The segments are being produced on site at the Align JV south portal site near Maple Cross in Hertfordshire, where there is storage for about 1,400 segments or enough for three months of excavation. The segments are mostly fibre reinforced, with some rebar in places, and will be transported by multi-service vehicles directly from the production site into the tunnel.

In addition to the Krokodyl robot, the TBMs feature mini annular grout batching plants located on the machines, removing the need to pre-mix the grout and transport it to the working face. Once launched, the machines will operate almost continuously, 24 hours a day, 7 days per week, for 3.5 years, driving as deep as 80m below ground.

The Long Itchington Wood machine, also in delivery from Herrenknecht, will launch from a north portal of the twin tube alignments and will take about five months to complete the 1.6km drive. The TBM will then be retrieved and be transported back to the north portal to drive the parallel tube. A 200m cut-and-cover section will be constructed from the south portal box to form the southern end of the Long Itchington Wood alignment.

In addition to the Align and BBV TBMs, two more machines have been ordered from Herrenknecht by the Skanska-Costain-Strabag JV, SCS, to excavate the 8km x 8.8m i.d. Northolt West drives as part of the 21km underground route into the HS2 London terminus at Euston Station.

Procurement of the remaining five main TBMs for HS2 is yet to start. One of these will excavate the 5.6km Bromford alignments on the approach to Birmingham Curzon Street Station for BBV. The remaining four are required by SCS to drive the 5.5km Northolt East and 7.2km Euston alignments that complete the HS2 approach into Euston Station.

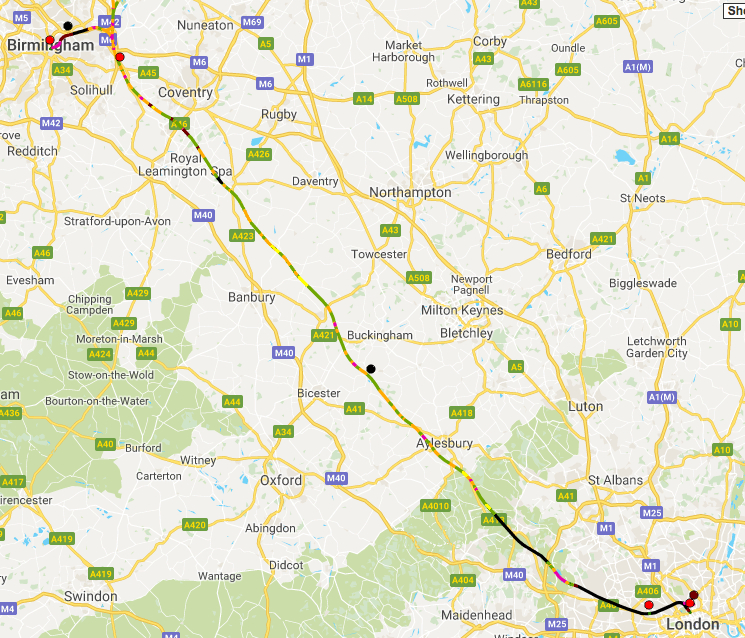

In total, about 53km of the 225km route between Birmingham and London will be underground, of which 45km will be excavated by TBM and 7.6km will be cut-and-cover. With twin tubes required for all underground sections, the ten HS2 TBMs will have excavated 90km by the end of construction.

Track systems and M&E contracts

Supply of the track systems for the first phase of the project and the link to Crewe is divided into four lots:

- Lot 1 - Urban London and Birmingham - £434 million

- Lot 2 - Open Route Central - £526 million

- Lot 3 - Open Route North - £566 million

- Lot 4 - Phase 2a Birmingham to Crewe - £431 million

About 53km of HS2 Phase 1 is underground (in black), 45km in TBM bores and 8km in cut-and-cover structures

Four teams have been shortlisted to bid for the contracts:

- BBVT JV of Balfour Beatty, ETF and TSO

- Ferrovial-BAM Nuttall JV

- Colas Rail

- Strabag-Rhomberg Sersa JV (not shortlisted for Lot 3)

Three teams have shortlisted for the £498 million contract to deliver the design, supply, manufacture, installation, testing, commissioning and maintenance (until handover) of the M&E services, which will include tunnel ventilation systems and services in shafts, tunnels and cross-passages, for Phases 1 and 2a. The shortlisted teams are:

- Alstom Transport UK

- Balfour Beatty NG Bailey, BBB, JV

- Costain Group

Both track and M&E contracts are expected to be awarded in 2022.

References

- First TBMs for HS2 London route ordered – TunnelTalk, October 2020

- HS2 station shortlist as work sites mobilise – TunnelTalk, June 2020

First three HS2 TBMs ordered and in manufacture 28 May 2020

The first three TBMs to be used on the HS2 high speed rail project in the UK are on order and in fabrication at the Herrenknecht factory in Germany. These three TBMs, as the first of a total 10 TBMs needed for the project, are on order by the Align JV, of Bouygues Travaux Publics, Sir Robert McAlpine and VolkerFitzpatrick for central contract package C1, and by the BBV Balfour Beatty Vinci JV on its contract packages N1 and N2 at the north end of the line. The first two machines to be delivered later in 2020 are 10.26m in diameter and will be used by the Align JV to excavate the 16km long twin tube tunnels through the Chiltern Hills running northwest from just inside the M25m orbital motorway around London to South Heath in Buckinghamshire. The third machine for the BBV JV, is one of two machines it will need for excavation of the 2.8km long twin tube tunnel on the approach to the new Birmingham International Station. All three TBMs are of the Herrenknecht variable density slurry design.

The two 170m long, 2,000 tonne, variable density machines for the Align JV will spend about three and half years excavating the Chiltern tunnels, which are the longest and deepest on the HS2 Phase 1 route from the Euston Station terminus in London to the Curzon Street Station terminus in Birmingham. They are programmed to work on a 24 hour, seven days a week schedule, stopping only for the end of year and public holidays.

The tunnels run up to 80m below the Chilterns working mainly through chalk geology with a reach of chalk with hard flint inclusions at the north ned. As the machines progress they will erect a segmental lining to 9.1m i.d. in rings of 2m wide. About 112,000 segments, each weighing about 8.5 tonne on average, will be required to complete the total 34km of the 17km long twin running tunnels.

About 56km of the 215km long high-speed railway line from London to Birmingham will be in tunnels. For excavation of these tunnels, BBV will oreder a second TBM for its twin tube drives in Birmingham and the SCS Skanska, Costain, Strabag JV will require six TBMs, two for excavation of the 7km-long Euston tunnels between Euston and Old Oak Common Stations in London and another four for the 14km-long Northolt Tunnels on its contract packages S1 and S2.

In contract packages C2 and C3 by the EKFB, Eiffage, Kier, Ferrovial, BAM Nuttall JV there is the green tunnel which is planned as a cut and cover operation.

In industry tradition, and in honour of Santa Barbara as the patron saint of miners and tunnellers, the TBMs will be given female names ahead of launch. In a competition among pupils of local schools, the first two TBMs will be named after a short list of three famous women: Cecilia Payne-Gaposchkin, the astronomer and astrophysicist born in Buckinghamshire who became Chair of Astronomy at Harvard University in the USA; Florence Nightingale, the founder of modern nursing, who spent many years in Claydon, Buckinghamshire where she wrote numerous books on nursing; and Marie Curie, the first woman to win a Nobel Prize, and the first person and the only woman to win the Nobel Prize twice.

The suppliers and names of the additional TBMs to be employed on the £35-45 billion Phase 1 project will be reported as the information becomes known and confirmed. TunnelTalk is prepared to continue its coverage of this important project into and through construction, and on to the programmed phased opening of full line between 2029 and 2036.

References

- Notice to proceed granted for HS2 construction – TunnelTalk, Aprill 2020

- Civil contract awards for UK HS2 Phase I – TunnelTalk, July 2017

- Speed up delivery to cut costs of HS2 – TunnelTalk, March 2014

- High-speed rail pitch for the UK – TunnelTalk, August 2009

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.