One main drive remains for Tideway TBMs 02 Dec 2020

Excavation of the main 7.3m i.d. Tideway CSO interceptor under the River Thames in London has focused on the 65m deep x 20m i.d. Chambers Wharf shaft with one TBM breaking through in late November 2020 and another preparing to launch. Elsewhere, casting of the secondary lining has begun on the Central Contract between Carnwath Road and Kirtling Street. "So far, the team has poured one 12m shutter," Tideway confirmed in an emailed statement.

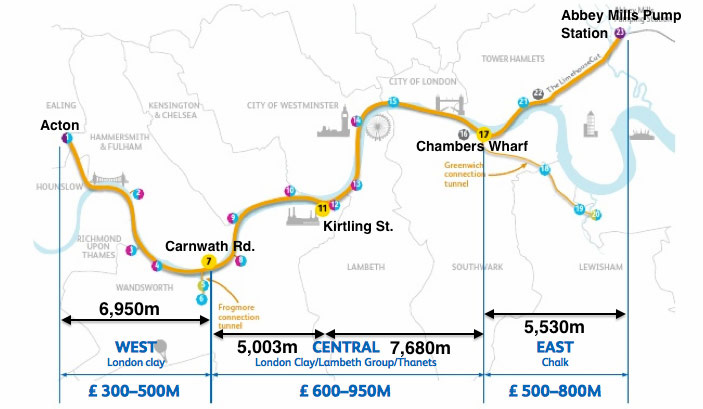

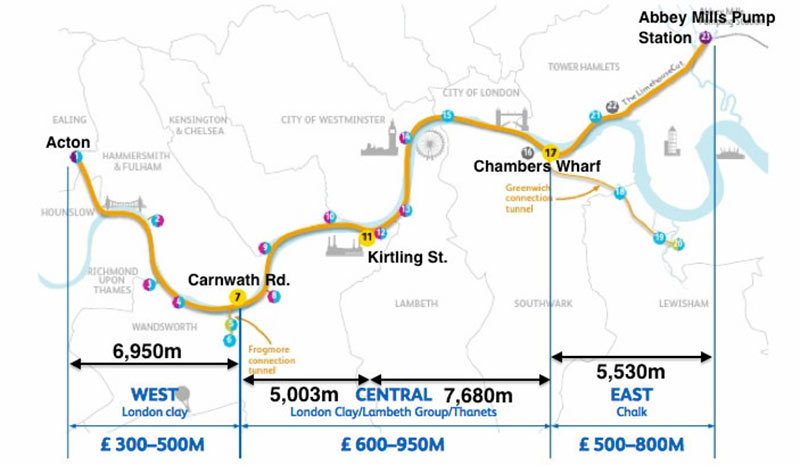

Completion of the second Central Contract drive was announced on 1 December 2020, after the NFM EPBM finished its 7.6km excavation from Kirtling Street, the longest of the Tideway main drives, for the Ferrovial-Laing-O’Rourke (FLO) JV (Fig 1). The machine will remain in place in the shaft, while a Herrenknecht slurry machine is prepared for launch by the Costain-Vincy-Bachy Soletanche (CVB) JV on its 5.5km drive to Abbey Mills pumping station, part of the East Contract, with launch due imminently.

“The longest single Tideway drive has taken place through a mix of geology, including clay, gravel and chalk, requiring significant expertise to quickly and safely adapt the tools on the cutterhead as needed,” said Tim Newman, Tideway Project Geologist. “Completing it is a real achievement, especially in this challenging year.”

More than 1 million tonne of spoil was generated during the 7.6km drive, all of which was removed from the site by barge. Barges were also used to transport concrete segments to site with 4,227 rings needed to line the drive.

Breakthrough at the Chambers Wharf shaft, which was constructed by hydrofraise as part of the East Contract package of work, now means that 19km of the main interceptor has been completed with only the East Contract excavations, through the Seaford Chalk and under water pressures of up to 5 bar, remaining. Also part of the East Contract, a second 6.5m diameter Herrenknecht slurry machine was launched in early December to bore the 4.6km x 5.5m i.d. connector between Greenwich pumping station and Chambers Wharf.

Work on Tideway has continued despite a resurgence of Covid-19 infections in the UK that led to a second nationwide lockdown in England through November 2020. The pandemic has not been without its costs. In its most recent quarterly report, Tideway confirmed that Covid-19 would add £233 million to completion of the project, which now totals £4.1 billion from an initial £3.4 billion estimate at start of construction (£3.1 billion in 2014/15 prices).

Start of commissioning is now also expected in September 2021, later than originally forecast, with handover in March 2025, a nine-month delay that Tideway blames entirely on “a slowdown in productivity due to the essential Covid-safe measures in place on sites.”

The revised dates are “based on an assumption that these measures continue to have an impact until May 2021”. Further delay is considered unlikely, as the safety measures taken on site have allowed work to “continue successfully as the anticipated second wave materialised in the Autumn and production has increased to near pre-Covid-19 levels, ultimately mitigating significant potential cost and schedule increases above those forecast”.

Launch of the formwork on the Carnwath Road to Kirtling Street section of the Central Contract, is the start of the inner lining work on the main interceptor. Secondary lining of the Frogmore connector, part of the West Contract, from Dormay Street to King George's Park is complete with lining of the section from Dormay Street to Carnwath Road to begin in Spring 2021, as will lining on the main West Contract alignment between Carnwath Road and Acton Storm Tanks.

To date, 19 of the shafts on the project are also complete, with two remaining to sink, and work continues on the various short connectors to link CSO locations to the main interceptor, two of which have recently been completed. The second longest, the 212m pipejacked Barn Elms connector, was completed in October by subcontractor Barhale for main West Contract contractor the BMB JV of BAM Nuttall-Morgan Sindall-Balfour Beatty. Completion was achieved despite difficult conditions in the early stages of the pipejack that resulted in damage to some of the reinforced concrete jacking pipes.

In November, excavation of the 147m long Cremorne Wharf SCL connector to the segmental lining of the main interceptor on the Central Contract was completed. Breakthrough will wait until construction of the main line is complete. SCL excavation of the longest of the short connectors, the 300m Hammersmith alignment, was completed in early 2019.

References

- Second of four main Tideway drives breakthrough – TunnelTalk, October 2020

- Tideway continues and counts the cost of Covid – TunnelTalk, August 2020

- Tideway TBMs well into excavations – TunnelTalk, September 2019

- Connection construction underway for Tideway – TunnelTalk, September 2017

Second of four main Tideway drives breakthroughs 01 Oct 2020

A second TBM excavating the main 25km long Tideway CSO interceptor under the River Thames in London has broken through. Breakthrough was at the end of the 7km drive of the West Contract from the launch shaft at Carnwath Road to Acton Storm Tanks for the BAM Nuttall-Morgan Sindall-Balfour Beatty (BMB) JV. The 8.8m diameter machine began tunnelling in May 2019 and excavated about 725,000 tonne of material to reach the reception shaft at Acton, the westernmost point of the Tideway route (Fig 1).

The breakthrough completes TBM excavations on the West Contract, after a refurbished Lovat EPBM completed the 1.1km long Frogmore connector between King George’s Park and Carnwath Road in July 2020.

The first Tideway TBM breakthrough on the 7.3m i.d. main line was the 5km reach between Kirtling Street and Carnwath Road on the Central Contract, completing its drive in November 2019 for the Ferrovial-Laing O'Rourke (FLO) JV. Casting of the 250mm thick secondary concrete lining on this section is expected to begin "within the next month or so," Tideway told TunnelTalk. The lining is to be cast using two 12m shutters supplied by TecoZam of Spain. Each 12m long shutter is supported on a 34m traveller (Fig 1). The traveller was split into four parts for lowering down the shaft and reassembled underground. The secondary lining is reinforced with 30kg of ArcelorMittal steel fibre/m3 of concrete.

Two of the four main TBM drives for the project now remain to be completed. An NFM EPBM is currently 6.3km into the longest 7.5km Tideway drive on the Central Contract between Kirtling Street and Chambers Wharf and a Herrenknecht slurry machine is underground but is yet to launch on its 5.5km drive for the East Contract between Chambers Wharf east to Abbey Mills pumping station, for contractor Costain-Vinci-Bachy Soletanche (CVB) JV. A final TBM, another Herrenknecht slurry machine, is also underground and preparing to launch on the 4.6km long x 5.5m o.d. Greenwich connector on the East Contract (Fig 2). Both East Contract TBMs are expected to launch by the end of the year.

“Having broken through, it is easy to forget the time and effort that goes into making these excavations possible,” said Neil Binns, Senior Project Manager for Tideway. “It is an example of the teamwork required to clean up the River Thames.”

References

- Tideway continues and counts the cost of Covid – TunnelTalk, August 2020

- Tideway TBMs more than a third through drives – TunnelTalk, March 2020

- Tideway TBMs well into excavations – TunnelTalk, September 2019

- Connection construction underway for Tideway – TunnelTalk, September 2017

Tideway continues and counts cost of Covid 20 Aug 2020

The last TBM to work on the main tunnel for the Tideway CSO project under the River Thames in London arrived on site in Bermondsey from manufacturer Herrenknecht in late July 2020. The slurry machine will drive the 5.5km section of the main interceptor from its Chambers Wharf launch site to the Abbey Mills pumping station (Fig 1). As part of the East Contract, being constructed by the Costain-Vinci-Bachy Soletranche JV, it is the last TBM to launch on the main 25km x 7.2m i.d. Tideway alignment, which extends from Acton in the west to Abbey Mills, where it connects with the existing Lee Tunnel for conveyance of combined storm water onwards to the Beckton sewage treatment works (Fig 1).

Launch of the TBM is expected in late 2020 with completion in 2022. Manufacture of the precast segmental lining is already underway at a plant in Tallington, Lincolnshire, where they are also being stored, before transport to Thamesport in Kent, and then up the river to Chambers Wharf.

The final main line TBM was “always expected to begin later in the programme than at other launch sites,” said Tideway in an email statement. “The preparatory work required at Chambers Wharf was more extensive. A cofferdam had to be built before construction of the shaft could start and the shaft itself is the deepest on the project,” at about 64m deep.

Of the four TBMs working on the main Tideway CSO alignment, there are currently two in operation, after the 5km Kirtling Street-to-Carnwath Road drive of the Central Contract was completed by its NFM EPBM for contractor Ferrovial-Laing O'Rourke (FLO) JV in November 2019.

A second NFM EPBM on the Central Contract is currently about 5.5km into its 7.5km drive between Kirtling Street and Chambers Wharf after a stoppage between February and June. The stoppage was originally planned to prepare the cutterhead for the different ground conditions under east London but was extended beyond its scheduled restart after Tideway closed all construction as a result of the coronavirus pandemic.

The work to the cutterhead included replacing more than 300 tools, including drag bits, arm/nose rippers, bucket scrapers and disc cutters, in preparation for the drive into the Upnor Formation and Thanet Sands, both of which are known for their abrasiveness to TBM cutting tools.

Restarting this element of the project, the longest of the main Tideway drives, was “one of the most challenging under new safety guidelines”, said Paul Hallows, Site Manager at Kirtling Street for the Ferrovial-Laing O'Rourke (FLO) JV in a June 2020 press release. “There is still much work required to get us to Chambers Wharf, but we are confident we can finish this section of tunnel, meeting the same standards as we have already set.” Tideway expects breakthrough of this eastward drive of the Central Contract later this year.

Casting of the inner in-situ concrete lining in the main drive of the Central Contract from the Kirtling Street to the Carnwath Road is also getting started. The first of two 34m long shutters, weighing about 240 tonne each, has been lowered to the bottom of the Kirtling Street access shaft following completion of the westbound TBM at Carnwath Road in November 2019. Due to the size and weight of the full round shutter, it was split into four pieces for lowering into to the bottom of the shaft for reassembly in the starter tunnel.

The shutters will cast a 250mm thick concrete lining inside the primary segmental lining, reducing the i.d. to 7.3m diameter. The secondary lining provides further resistance to abrasion to ensure the 120-year design life of the infrastructure. Sewage in Tideway will flow by gravity eastward with no need for intermediate pumps until lifted by pumps into the Beckton sewage treatment works at the end of the Lee Tunnel.

The final TBM on the main Tideway alignment, a Herrenknecht EPBM on the West Contract, is almost 5.5km into its 6.5km drive between Carnwath Road and Acton Storm Tanks. Its progress was also halted by the pandemic in March with contractor, the BAM Nuttall-Morgan Sindall-Balfour Beatty, restarting tunnelling on 13 May. Tideway is still assessing the impact of the shutdown on the breakthrough date.

Excavation on the TBM connectors

In addition to the main interceptor, Tideway includes two long TBM excavated connectors, the Frogmore long connector as part of the West Contract and the Greenwich connector as part of the East Contract.

The 1.1km x 2.5m i.d. Frogmore connector broke through to the main CSO alignment at the Carnwath Road shaft in July 2020. The connector was excavated in two drives from a central launch shaft at Dormay Street by the BAM Nuttall-Morgan Sindall-Balfour Beatty JV using a refurbished Lovat EPBM. The first 500m southward drive to King George’s Park was completed in October 2019 and the second 600m drive from Dormay Street northward to Carnwath Road in January 2020.

Meanwhile, the Costain-Vinci-Bachy Soletranche JV on the East Contract is preparing to launch a Herrenkencht slurry TBM on the 4.6km x 5.5m i.d. Greenwich connector between Greenwich pumping station and Chambers Wharf where it will join the main Tideway alignment. In July, its tailshield and cutterhead were finally lowered into the launch shaft, after a delay in transporting the machine the 3 miles from its Victoria Deep assembly site in North Greenwich, where it had arrived a year ago in late July 2019.

The time taken to transport the machine from assembly to launch site was explained by Tideway as “a number of logistical challenges in getting the TBM to the launch site in one piece.” With lockdown reducing the size of crew available to transport the machine, “the decision was made to split the machine down into a number of parts, transport to the launch site, and re-assemble on site.” Tunnelling is now expected to begin on the Greenwich connector in November 2020 for completion in Summer 2022.

Tideway and the pandemic

Although unavoidable, Tideway is counting the cost of the coronavirus pandemic shutdown. The predicted budget for the project had already increased from an initial £3.4 billion (£3.1 billion in 2014/15 prices) to £3.9 billion. Following the pandemic shutdown Tideway has released a ‘plausible downside scenario’ and ‘severe downside scenario’, as part of its latest annual report.

Under the plausible downside scenario, the costs to complete the project are 9% higher than forecast, taking the total cost to £4.1 billion. Under the worst-case scenario, costs to completion increase by 24%, taking the total to £4.3 billion.

On the advice of the UK Government, non-essential construction on the project was paused during the week of 23 March, with only the West Contract TBM drive to Acton Storm Tanks and pipe-jacking work at Putney continuing. “We could not stop the TBM in its position beneath the river wall, so it was progressed at the start of lockdown and then paused. Stopping the pipe-jacking may have risked settlement,” Tideway told TunnelTalk.

Resuming activities at all working sites has involved a “site-by-site approach to the implementation of new safety measures,” said Tideway, including the introduction of staggered shift patterns, one-way walkways, contact-free entry to site, social-distancing in its welfare facilities, and encouraging workers to avoid public transport.

“We did what we had to,” said Andy Mitchell, Tideway CEO, in the annual report. “We paused our work on site and brought tunnelling to a safe stop. Every member of staff who was able to, began working from home. We gave assurances to our supply chain that we would continue to pay them, so they in turn could protect their own workforce. This was the right thing to do.”

As a result, Tideway reports that it was able to “safely re-mobilise our operations, with the same, highly skilled team in place. We remain on track to deliver all works by 2024.” A detailed assessment of the impact of the pandemic is expected to be published later in the year with Tideway “working with all stakeholders including our contractors and our regulator” to prepare this.

References

- Tideway TBMs more than a third through drives – TunnelTalk, March 2020

- Preparations to start London supersewer excavations – TunnelTalk, August 2017

- Preferred bidders selected for Thames Tideway – TunnelTalk, February 2015

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.