Crossover XRE navigates fault zones in Turkey 18 Jun 2020

In the mountains outside of Ankara, a 5.5m diameter Robbins Crossover XRE TBM bored the final 9km leg of the 31.6km long Gerede Water Transmission Tunnel by navigating 48 fault zones and hydrostatic pressures up to 26 bar. The notoriously difficult conditions had previously caused two non-Robbins double shield TBMs to become stuck in massive inrushes of mud and water.

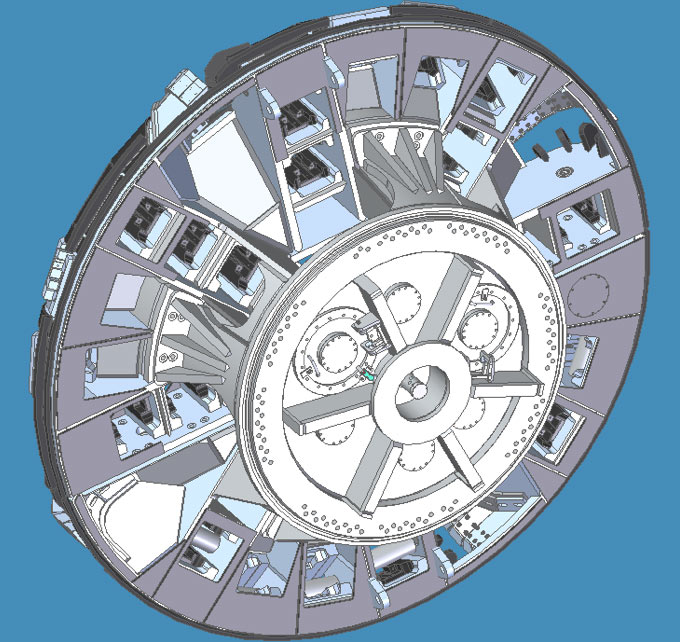

Preliminary geologic testing and borehole samples showed a mix of volcanic rock including tuff, basalt, and breccia, giving way to sedimentary formations like sandstone, shale, and limestone, all punctuated by fault zones. The 31.6km long tunnel would pull water from the Gerede River to a water storage system near Ankara, making it the longest such water tunnel in Turkey (Fig 1).

After two of the three original TBMs became irretrievably stuck or damaged, the Kolin/Limak JV contacted The Robbins Company, who suggested a Crossover dual-mode type TBM for the remaining 9km section of tunnel. The 5.56m diameter XRE could effectively bore conditions in both rock and mixed ground under water pressure by converting between modes. The revised geology was now understood to contain more significant fault zones and an aquifer system that could cause high-pressure water inrushes of up to 20 bar. However, the ground was expected to improve as the TBM advanced and consist mostly of sandstone, limestone and tuff with a maximum UCS in the range of 100MPa. Kolin/Limak needed a machine that could effectively bore in those wide-ranging conditions, but also statically hold water pressure up to 20 bar in the event of an emergency flow – a failsafe that none of the standard double shield TBMs were equipped with.

Cutterhead

Due to the geology, the Gerede machine required a unique Crossover cutterhead. The cutterhead has the face and internal structure of a hard rock machine with the open rear structure of an EPB. On a standard hard rock machine, rock is scooped up in the buckets and as the head rotates, rock slides from the bucket onto a belt conveyor in the center of the machine which minimizes wear. Instead, this machine has a screw conveyor at the bottom of the chamber to aid in cutterhead cleaning in the event of a fault zone. Thus, rocks entering the cutterhead now have the entire height of the machine to fall. In order to reduce damage from large falling rocks, the pedestal was specially designed with multiple deflector plates to slow the fall (Fig 2). The cutterhead buckets were also designed to direct the muck from the face by pushing it backward into the cutting chamber. Because of the open back design, this cutterhead can also be converted to an EPB head if conditions require it. In addition, the cutterhead is designed to operate in a single direction to allow for greater efficiency while excavating, with lower power requirements and less chance of regrind.

Main drives

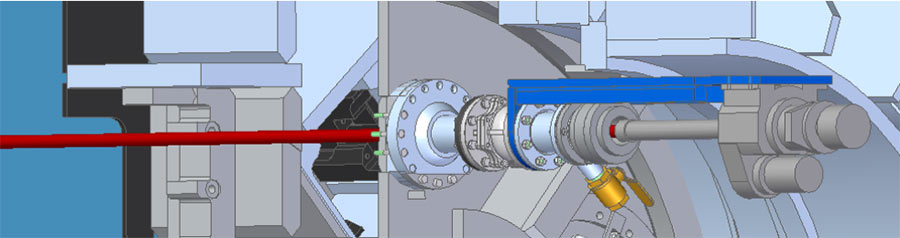

A new feature on the Gerede machine, which will also be supplied on all subsequent Crossover machines, is the two-speed gearbox. With the ability to shift into two speeds, the machine can easily bore through different types of ground. For hard rock, the machine can run in a high rpm/low torque and for EPB mode, it can shift into a low rpm/high torque. The low rpm/high torque allows the machine to bore through fault zones and soft ground without becoming stuck like an EPBM (Fig 3).

Seals

Due to previous experiences at Gerede, the new TBM is designed to statically hold up to 20 bar pressure in the event of a massive water inflow. In order to protect the machine from such high water pressure, an extensive sealing system has been put into place. Around the main bearing, there is an outer row of six seals and an inner row of three seals. Between each seal, the cavity is filled with pressurized grease to ensure a constant pressure in each of the cavities (Fig 4). In the event that the machine is shut down and an inrush of water overtakes the machine, a pressure sensor will detect this presence of water and pressurize each cavity with grease in order to continually protect the seals from the pace pressure. The articulation joint, gripper and stabilizer shoes are sealed off in the same manner. All of these locations have two rows of seals with a grease-filled pressure controlled cavity between to hold constant pressure. The tail seals are also sealed off in the same manner, but this location has four rows of seals.

| Table 1: Gerede XRE TBM Specifications | |||

| Tunnel design parameters | |||

| Vertical and horizontal curve radius | 500m | ||

| Gradient | ± 0.5° | ||

| UCS | Average 100MPa | ||

| Hydrostatic pressure | 20 bar | ||

| Segmental lining | 5+1 key | ||

| Segment width | 1,400mm | ||

| Segment thickness | 350mm | ||

| Segment backfill | Single component grout | ||

| TBM specification parameters | |||

| Bore diameter | 5.605m | ||

| Cutterhead style | Mixed ground, convertible | ||

| Cutters | 17in disc cutters, back-loading | ||

| Cutterhead drive motors | 8 x 210kW = 1,680kW | ||

| Cutterhead speed Low gear |

0-1.73rpm (constant torque range) 1.73-3.54rpm (constant power range) 0-4.22rpm (constant torque range) |

||

| High gear | 4.22-8.61rpm (constant power range) 8.61-10.0rpm (reduced power range) |

||

| Breakout Torque Maximum Thrust |

13,896kNm 42,000 kN |

||

| TBM screw conveyor | Shafted, hydraulic drive | ||

| Probe drill/grout | 12 peripheral ports, 10 bulkhead ports; 2 drills | ||

| Methane protection monitors | 6 locations | ||

| Explosion-proof EPB sensors | 6 locations | ||

| TBM total length and weight | 221m, 470 tonne | ||

Screw conveyor

Perhaps one of the most important parts of the Gerede TBM design is the screw conveyor, which has the ability to seal itself off so that if a fault zone is encountered with large amounts of water, the machine will still be able to continue excavation. In this case, the screw can be used in a sequential operation. First, the rear discharge gate is closed, sealing off the interior of the machine from the incoming water. The screw extension cylinders will then push the rear of the screw back, thus pulling the screw out of the cutting chamber and inside of the screw casings. Next, the bulkhead gate is closed and the screw conveyor is dewatered. The rear discharge gate can be reopened and the screw conveyor can run, emptying the casings of muck. A catchment basin, under the hopper of the bridge conveyor, can be filled with leftover water coming from the screw. The water is then pumped out of the back-up system. Once the screw has been emptied, the rear discharge gate can be sealed. The bulkhead gates can be reopened and the screw extended into the cutting chamber. Boring can then commence until the screw conveyor is once again full. Once the screw is refilled, it can again be retracted and sealed, starting the process over again. This process can be slow, but it can get the machine through a fault zone and into better ground.

Probe drilling

Due to the unpredictable ground conditions, it was necessary to detect and grout off zones of concern wherever possible in order to protect the machine from flowing ground and water pressure. The Gerede machine achieved this using a standard array of twelve 100mm diameter ports angled at 7° spaced equally around the rear shield. Each port is sealed by a ball valve until it is needed for probing. There are also ten of the same sized ports straight through the forward shield for probing and grouting. Six additional hatches are built into the pedestal at the front of the machine. The hatches are equipped to mount an optional pneumatic percussive drill that can be used in the center section of the cutterhead (Fig 5).

The probe drills on the Gerede machine also had an extra feature for emergency cases. The drills are designed to pull back behind the tail shield and at an angle of 16°, so they can drill behind the shields and into the segment lining. If water has filled the cutting chamber and the pressure is great, drilling a hole in the roof of the tunnel will allow the water to spill out, thus relieving the buildup of pressure on the machine and the segment ring (Fig 6).

Excavation

The Crossover machine began boring at a slight angle to the rest of the tunnel and in a fault zone, bypassing the stuck machine before gradually meeting up with the original tunnel alignment. The machine was required to be used in EPB mode as it encountered water pressures up to 23 bars, alluvium, flowing materials, and clay. Water pressure was lowered by draining the ground water through the rear shield probe drill ports, which were equipped with normally-closed ball valves. Probe drilling became routine after advancing 50m past the section that buried the original double shield TBM. The Crossover machine bored at about 30mm/min through the first bad section of ground, with any limitations in speed the result of the existing tunnel belt conveyor, which tended to have spillage issues resulting in significant clean-up. Despite the challenges, crews were able to bore 80m to the side of where the original machine is currently buried and pass it.

As the machine continued excavating, it encountered a mixture of volcanic rock including tuff, agglomerate, and basalt while using systematic probe drilling. Due to the seismically active region, these formations were punctuated by a series of fault zones containing squeezing clay and water. By the end of tunnelling, the TBM had crossed 48 such fault zones and statically held back 26 bar water pressure. Each time a zone was encountered, exceptional thrust was used to keep the machine from becoming stuck combined with dewatering to lower the water pressure. The rear discharge gate was sealed at these times and the machine was operated in a sequential fashion. By keeping the TBM advance rate, RPM, and screw conveyor at an optimal level, the machine was able to navigate the squeezing conditions in clay. TBM advance rates are shown in Table 2.

| Table 2: Best & Average TBM Advance Rates | |||

| Best Day | 29.4m | Average Day | 9.49m |

| Best Week | 134.6m | Average Week | 71.14m |

| Best Month | 484.0m | Average Month | 284.54m |

With careful design and planning, Crossover machines can be a viable alternative for tunneling in very challenging conditions that would be difficult for conventional machine configurations. In opting for a Crossover machine, several factors must be seriously considered by consultants or contractors at the time of machine selection, including cost, time, logistics, maintenance, risk, and tunnel design, but benefits can often outweigh negative factors, and result in significant cost benefits.

References

- XRE TBM conquers toughest drive in Turkey – TunnelTalk, February 2019

- Crossover TBM for hard rock Mumbai Metro drives – TunnelTalk, March 2020

- Robbins returns to Siberia for Severomuysky 2 – TunnelTalk, December 2019

- Equipping TBMs for tough conditions – TunnelTalk, November 2019

- Keep your TBM moving against the odds – TunnelTalk, June 2017

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.