Perth's promising rail tunnel relationship Sep 2004

Tunnelling beneath any city is an exercise in risk management, for which the parties take responsibility not only for public safety, construction time, cost and quality, but also the wider reputation of tunnelling internationally. For teams engaged on the excavation of 2km of rail tunnel beneath the centre of Perth, Western Australia - easily the most challenging part of the new 72km-long rail line south to Mandurah - awareness of these responsibilities is acute.

From the first presentation of the 100% government funded project to the citizens of Perth and Western Australia, public interest, feedback, and comment have been loud. Along with comments that the city does not need the new dedicated rail line at all, there were persuasive calls to investigate less expensive routes around or over the central business district (CBD).

Fig 1. The route of the new Mandurah rail line service in Perth incorporates 2km of tunnelled and subsurface alignment

All lost out finally to the new line with an underground city route when Premier Geoff Gallop's State Government administration approved the Aust$1.5 billion (US$1.06 billion) project for an operational date of December 2006. This extends a tradition in Western Australia of providing efficient transportation systems in and around this gem city, located on the banks of the Swan River and the beaches of the Indian Ocean coast.

Within the Aust$1.5 billion New Metrorail budget, $300 million covers the cost of 93 new rail cars for the line, with another $350 million allocated to the underground city centre section (Fig 1). The underground works comprise twin 770m-long x 6.1m i.d. precast concrete bolted and gasketed segmental lined running tunnels, with a total 475m of cut-and-cover tunnel and transition ramps, and two open-cut subsurface stations.

The twin tunnels pass directly beneath historically protected buildings set on shallow concrete-strip and limestone-pad foundations and alongside several new deep pile foundation high-rise towers, including one of the city's three tallest, the Bank West Tower. Excavation also passes adjacent to the access ramp and sidewall of an underground public parking lot, as well as beneath some of the city's most heavily trafficked multi-lane roads and streets and 10m under the operating surface tracks of Perth's central railway station.

The arrangement

During a meeting with TunnelTalk in July 2004, Richard Mann, Director of City Project of New MetroRail, explained the environment in which the design-build tunnelling contract will progress. "The contract model was developed from a detailed risk-based assessment of procurement strategy carried out by key Government stakeholders," said Mann.

"Like other forms of risk-sharing management, a relationship contract requires the client and contractor to work together in a non-adversarial joint management manner. In our case, the relationship contract has a joint management board representing the last level of negotiation before any unresolved disputes advance to arbitration. It is built around client and contractor facilitators and a relationship management team, comprising representatives from both parties. The facilitators are the go-betweens, to ensure the parties remain engaged equally and continue to communicate, and the joint management team assesses performance via regular progress meetings and identifies actions to promote cooperation and joint resolution of problems. There is a formal relationship management plan written by the management team and included in the contractor's management system. There is also a strong emphasis on leadership, which is recognized as vital for this form of project management to function successfully." Through this vehicle, explained Mann, the team expects to deal successfully with third party project stakeholders, control time and costs, avoid disputes, and provide an overall win-win conclusion.

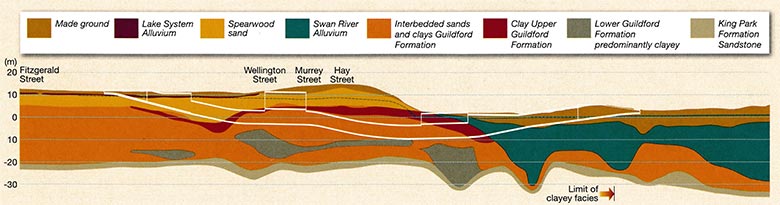

Given the logistics of the project, all these tools of management may well be employed to the ultimate. Not only is the project directly within the CBD, the underground works lie predominantly in soft alluvial sands and gravels with an anticipated ravelling or flowing behaviour, all beneath a high groundwater table, under shallow cover of 12m to 15m, and in one of the most publicly engaged and industrially unionized states of Australia (Fig 2).

"All of these aspects have been considered and approached formally in the contract," said Mann. The contract has negotiated a site-specific labour agreement with the workers and construction unions in Western Australia. For cost control, this is a fixed-price lump-sum contract. Any changes in scope will be born by the owner, while the contractor carries control of all the design and construction costs. There is a joint value engineering facility through which cost savings are shared equally. In dealing with third party stakeholders, there is no handover of responsibility to contractors.

Relationships established with third party stakeholders during earlier planning stages are retained through the client's ongoing working relationship with the contractor. Actual cost of damage sustained below a contract limit - for which the design-build team has prepared a thorough prediction assessment and has been seen to have complied fully with its approved buildings protection strategy - will be met without delay by the project owner, Perth's Public Transport Authority (PTA). Defects liability beyond the contractual limit is the responsibility of the contractor.

Quantifying and allocating management of risk seems to be the unmasked principle from which the Perth rail line excavation works were approached. "From the outset," said Mann, "the construction plan has evolved from a detailed risk assessment with input from the State Government Treasury, the State's Crown Solicitor, and a long list of independent consultants and specialists in various aspects of heavy civil construction and tunnel excavation in urban areas. The treatment plans developed as a result have been tightly aligned to the contract strategies."

Geotechnical investigation

All these plans and strategies are based on what is said to be the most thorough geotechnical investigation of the Perth region ever. The investigations produced ground settlement predictions, assessed potential settlement damage to the different buildings within the field of influence, and established a preparatory program of protection measures including underpinning and permeation grouting. They also determined specification of closed-face pressurized TBM excavation for the two 770m-long x 6.1m i.d. bored tunnels, and strictly limited groundwater drawdown in the loose alluvial geological deposits.

It was on this basis, and at a preliminary design level that expressions of interest (EOls) for the lump-sum performance-criteria based, design-build contract were invited in March 2003. As well as excavation works, the contract includes design, procurement, and installation of all necessary M&E equipment - including track work, sets a 120-year design life criteria for all major structures, and incorporates a 10-year follow-up maintenance responsibility for all key components including M&E installations. As part of the EOI process, applicants were invited to propose further geotechnical investigation on which to assess risk management and construction methods.

Five EOI packages were received and their requests for further geotechnical investigations were compiled into a second phase of investigation carried out at the expense of the Public Transportation Authority (PTA). Eventually two groups were short-listed and again proponents were asked to propose further geotechnical work leading to a third phase of additional geotechnical investigations carried out by the PTA before the City Project capital works contract was awarded in February 2004 to the Leighton-Kumagai JV for a lump-sum design-build tender price of Aust$324 million (US$227 million).

Artist's impression of the Esplanade Station at the Swan River foreshore, adjacent to the new Perth Convention Center

"All the EOls were evaluated 100% on capability and technical merit," said Mann. "Within the selected JV, Kumagai listed extensive tunnel and excavation experience in soft ground urban areas, including metro projects in Delhi, Bangkok, Singapore, Hong Kong, and cities in Japan. In addition, the JV reported a sound financial statement, listed well-experienced and knowledgeable management personnel, and, importantly, demonstrated a commitment to cooperative project management through a relationship form of contract." Within the Leighton-Kumagai JV group, Maunsell is the structural designer, with Faber Maunsell of the UK designing the tunnel lining segments. The Hong Kong office of the Austrian parent company Geoconsult is the geotechnical engineer, Alstom is the M&E designer, supplier, and installer, and the SKM/SMEC JV is the engaged independent design verification engineer.

Following award of contract, the JV confirmed its order for Mitsubishi TBM #1649 from Japan. The 7m o.d. EPBM is scheduled to arrive in Perth in January 2005 where it will be launched from the open-cut Esplanade Station box in March 2005 to drive the eastside tunnel first.

Although allowed within the contract, EPB was selected over slurry technology for several reasons, according to Eric Hudson-Smith, Geotechnical Manager for the City Project contract. Boulders are not anticipated in the host geology, he said, and EPB excavation with conditioning foams was considered more applicable in the sand, gravels, and clays to be encountered. "There was concern of possible breach of slurry to ground surface through the sands and gravels and relatively shallow cover, as well as for the extra cost of a slurry system and the extra space needed for the separation plant set-up for the relatively short 770m twin-tube drive. There is also no slurry tunnel experience in Western Australia.

This will be the third EPB operation in Western Australia, the previous projects being the Lovat EPBM used for the materials transfer tunnel in Port Hedland in 1995 to 1996, and another Lovat EPBM for a sewer tunnel in Perth in 2000 to 2001. The possible differences in rate of advance between slurry and EPB systems was said not to have been considered when making the TBM selection.

Under the William Street alignment, the TBM tunnels are about half a diameter or about 3.5m apart, with the tracks about 10m apart in the island-platform stations. At the north end, the tunnels swing through a 135m-radius curve while passing about 10m beneath surface operating rail tracks into the Perth City rail station.

"Within the lump-sum design-build contract, the JV carries the risk of changed ground conditions," said Mann. "In addition to the three phases of geotechnical investigation undertaken by the PTA and the owner's reporting in the contract documents, the JV carried out its own investigation subsequent to being awarded the contract. All information was incorporated into the contractor's Geotechnical Interpretive Report and Ground Settlement, Building Protection, and Repair Plan." The contract requires the JV to install adequate monitoring instrumentation and gather data for interpretation. A database of at least a month's recordings must be compiled before excavation begins.

Demolishing buildings to make way for the William Street Station is also part of the design-build contract. These buildings were procured by the Western Australian Planning Commission (WAPC) during project development, as were the rights of subterranean title to allow tunnelling beneath adjacent private property buildings - ownership of which, for older titles, extends to the centre of the earth in Western Australia. "Once the station is built, the site will be released for private redevelopment," said Christine Moro, Communications Manager for the New MetroRail-City Project team. "Sale of the development rights will go towards recouping the $37.5 million paid out for project acquisitions and subterranean title rights.

"In demolishing the buildings, there is a requirement to retain the structure of the historical Wellington Building," continued Moro. "This will be supported on micro piles and eventually incorporated into the block's redevelopment, with the weight of the old building transferred and supported on the underground station."

Contingency and insurance

The project's budget includes a contingency and the scheme is also paying for project-wide material damage and public liability insurance coverage. "Early exposure to the British Tunnelling Society's Joint Code of Practice was important in this regard," said Mann. "We believe compliance with the code was critical in securing project insurance over a relatively short six-month period. The first compliance review by our insurers is an encouraging endorsement of the risk management strategy we have adopted." Worker compensation, professional indemnity, and plant and equipment insurance is for the contractor to secure.

Within the project policy, claims arising from uninsurable events will be reimbursed for both time and cost. For claims of force majeure the contractor will be granted time but not costs. In the event of meeting unidentified obstructions or unexpected public service structures, the JV will be compensated the cost of service relocation and a total of seven days for any one event and a maximum of 14 days over the contract period.

In respect to insuring the design and installation of temporary works, these are treated the same as the design of all permanent works within the design-build contract and the JV's Pl insurance. The design and construction is also influenced by the contract's 120-year design life criteria and its 10-year maintenance of all civil structures.

Progress to date

By late July 2004, when TunnelTalk visited the site, the JV had started work at the William Street and Esplanade sites. Demolition of buildings at the William Street site was well advanced ahead of installing diaphragm walls for the station box. At the Esplanade site, work to demolish a 30-year-old traffic viaduct was also well advanced.

The old viaduct is being eliminated as part of the new road traffic plans for the river foreshore area and also provides space for the new underground station and transition ramp to the surface for its onward passage over the Narrows Bridge. Sheet piling around the opencut station and around the launch box of the TBM drives was also advancing. The box is supported by 24m-deep sheet-piles and dewatering will assist core excavation to the 12m invert. Rather than an enclosed structure, the 138m-long x 10m deep Esplanade Station will be a subsurface box with a canopy roof.

Work was about to start also at a third work site at the north end transition ramp and breakthrough point for the TBM drives of the far side of the Perth Station approach tracks.

At present there are about 140 JV management staff and workers at the Williams Street site and in the project office and another 35 to 40 at the Esplanade site. Currently, Leighton-Kumagai is working a 35hr week for all surface works from 7am to 7pm, six days/week. When tunnelling starts in the first quarter of 2005, the TBM will operate on a 24/7 schedule. At that time the City Project's work force will peak at about 300.

The 138m-long x 22m-wide William Street station box is scheduled to be fully excavated to its 20m depth before the TBM breaks through on its first drive in June 2005. The machine will then be pulled through and re-launched at the far end for its next breakthrough at the north end reception transition ramp in September. Once transported back to the Esplanade launch chamber, the machine is due to start the second drive in November, for final breakthrough at the north ramp in April 2006.

"With little previous TBM project experience to draw on, we have had valuable assistance from the Land Transportation Authority (LTA) in Singapore in building our project approach and risk management strategies," said Mann. "It shared with us its extensive soft-ground metro experience in heavily built-up urban situations. We have also had significant assistance from colleagues in the UK and Hong Kong. We feel we have made every effort to cover all bases in regard to completing these tunnels safely and successfully, and feel we have a vehicle in the relationship form of contract that brings our contractor onboard towards that end as well."

The enthusiasm, confidence, and leadership spirit for building the team was certainly evident. The proof is now in project progress and the eventual outcome.

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.