Final account on the Sydney Alliance 01 Nov 2002

'Alliance' procurement of the Northside Storage Tunnel project in Sydney, Australia, succeeded in delivering 20km of interceptor sewer and two underground pumping stations within two years and nine months, before the start of the Sydney Olympic Games in September 2000. To close her series on this landmark project, Shani Wallis looks back on the experience to highlight the successes and examine the lessons learned.

Of the five key performance criteria governing the Northside Storage Tunnel procurement, the most critical was time. The 20km tunnel - to capture and retain sewage surcharges until pumped through the North Head treatment plant - had to be available for use at the start of the Sydney Olympic Games. On 13 September 2002, two days before the opening ceremony of the Games, the tunnel was accepted by the client, Sydney Water.

In May 1997, when the decision was taken to construct the Northside Storage Tunnel as a pre-Olympic Games priority, Sydney Water had just three years and four months to complete the project. "From that premise, we had to approach the project with some lateral thinking," said Allan Henderson, Program Director of Asset Solutions for Sydney Water and a member of the Project Alliance Leadership Team. "Conventional design-bid-build procurement would take at least six years, and we could not risk entering a conventional contract that would potentially expose us to cost increases and time delays. After reviewing the success of alliances in the off-shore drilling private sector, we recommended to the Board that the method be adopted for our project. As far as anyone knew, this would be the world's first 'alliance' procurement of a public sector capital works project and the first application of the method to a tunnel project."

Prior to official government approval, Sydney Water set about selecting the alliance team and concluded the necessary environmental impact statement (EIS). In late December 1997, the New South Wales State government approved the project, and in January 1998 the alliance agreement was signed. Along with Sydney Water, the principal partners comprised systems engineer Montgomery Watson (now MWH), design engineer Connell Wagner, and contractor Transfield. The alliance members were selected on a competitive basis that included evaluation of technical capability and a cultural acceptance of the alliance concept.

At this stage, commercial evaluations centred on corporate overheads, profit margins, and the risk/reward framework of the alliance agreement. A budget estimate of $300M to 400M (all costs are expressed in Australian dollars; the exchange rate in September 2002 is Aus$1 = US$0.55) was used as the basis for government approval, but little by way of site investigation or design development had yet been undertaken. "In effect, we were attempting to manage the project through 'future perfect' planning," said Henderson. "The project could not be designed in detail in advance and 'future perfect' thinking would be required throughout the project."

In signing up to the alliance, each company had to enter an entirely different working environment. All employees were housed in a single administrative building, in open-plan offices and under an environment governed by nine basic management principles, of which open-book accounting and a 'best for project' attitude was the most fundamental, closely followed by a 'no-blame' culture. In addition, the alliance agreement demanded: unconditional support from parent organisations, that parties could not sue each other unless due to wilful default by one or other of the parties, a project-wide insurance policy covering all project alliance participants including subcontractors, and, as owner, Sydney Water was the only member of the alliance with the right to suspend or terminate work.

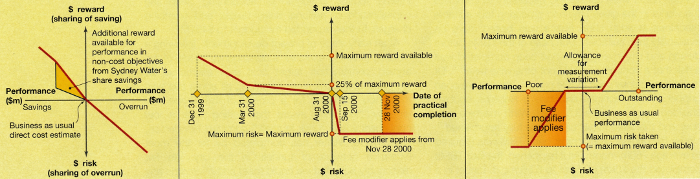

Commercially, the agreement provided a risk/reward regime based on performance, as defined under five key categories: time, cost, safety, community affairs, and the environment. Alliance partners pledged to better 'business as usual' (BAU) estimates, with performance comparisons registered from 'poor' to 'outstanding.' Financial rewards for performance above BAU estimates were payable on a sliding scale, with all objectives except cost having an agreed upper financial limit1. Financial penalties accrued as performance dropped below BAU. Incorporating the non-cost/schedule categories of safety, community affairs, and environment as key indicators was unusual. Performance in each category was assessed against benchmarks based on both processes and outcomes - except one. As the most critical performance indicator, time was based 100% on outcome and was weighted twice as high as the three non-financial indicators. Independent consultants reviewed the benchmarks and regularly assessed performance in all categories.

Time

Although relatively little was known about the precise ground conditions, it was clear that excavation through the familiar Hawkesbury Sandstone of Sydney would be by TBM, with underground plant rooms, adits, and TBM assembly chambers excavated by roadheaders or drill and blast. As an overflow retention facility, the tunnel is expected to operate about 20 times/year during heavy rainstorms, otherwise remaining dry. This permits periodic inspection and maintenance and allowed cost effective lining and support techniques.

Four TBMs were considered necessary to complete the works in the given time, and procuring four suitable machines at such short notice was based more on availability than suitability. Purchase of the TBMs before design and site investigation had been completed was a risk that a contractor would not otherwise take2. Of the four machines used on the project - three were open gripper Wirth machines and one was a Robbins doubleshielded machine - the 3.8m o.d. Wirth machine was new, and the three larger units were fully refurbished. Under the original programme, each TBM was required to average 760m/month. As it happened, the four TBMs completed the 20km of 3.8m to 6.56m o.d. tunnel in a total of 11 TBM production months with a combined best rate of 4,156m in a single month.

The physical construction risks from the outset were substantial. Extremely poor conditions and high water inflows encountered as the tunnel crossed one of three palaeochannels cost the alliance an extra three months on the excavation timeline and a great deal in extra materials. For this 210m zone under Middle Harbour at some 90m below sea level, forward probing and grouting required up to 54 grout holes drilled for every 4m to 6m advance of the TBM.

Within the reward/penalty regime of the alliance, there was a potential $1.6M bonus to earn on the time category. Of this, alliance partners earned a bonus of only $59,487, mainly due to the three-month delay under Middle Harbour. At average expenditure rates of about $0.5M/day, the delay cost some $30M.

Cost

The initial $300M to $400M budget was calculated without project-specific geological investigation, without detailed specification, and with no defined scope of works. At government approval stage, for example, the major branch tunnel to Scotts Creek was yet to be added. The first revised budget was established in mid-1998 and set an agreed construction target cost of $398M, but even at this stage - just six months into the project - geotechnical evaluations and detailed design were still being finalised. Subsequent allowances for an added connection to the tunnel at Shelly Beach, plus cost escalation on foreign exchange rates, owner's internal costs, changes to accounting (regarding capitalisation of notional sales taxes), and financing charges, further expanded the budget to $451M.

At an early stage of project development, following a detailed planning exercise, a contingency of 5% of the agreed construction target cost was estimated for identified cost risks. With hindsight, all agree this was much too optimistic for a project of this scope and urgency. "We were aware that setting such a low contingency was a risk in itself," admitted Henderson, "but Sydney Water has completed by far the most extensive network of tunnels in the city. We felt reasonably sure that we could meet and overcome any potential geological problems - perhaps the greatest risk to cover by contingency - particularly within the concept of alliance." This proved correct. Through the flexibility and unified culture of the alliance, the partners were focused on solving the technical problems in the shortest time and at the least additional cost.

In addition, cost increases in one area were offset by savings in others. One of the most significant savings was internal project management costs. Management on Sydney Water's recently completed Ocean Outfalls project represented 9.8% of the total project cost. On the Northside Storage Tunnel, project management costs totalled 1.6% of the project cost, representing substantial savings of $38M.

During construction, savings of some 2% were achieved through design changes and construction innovations. These included raising the tunnel alignment into more favourable rock in one area and redesigning two other critical areas to save five weeks on schedule. An improved understanding of rock conditions also enabled the team to reduce the extent of invert lining, and innovations to the facility's operating equipment led to savings on excavation of underground structures. Under a traditional contract, such design changes would have cost considerable time to implement and would have certainly increased costs.

Given these adjustments, and factoring in returns from the resale of plant and equipment, potential payouts on a set of significant project insurance claims, and final allocation of risk/reward to the alliance partners, an end of project financial statement presented to the government of New South Wales in April 2002 reported a final turnout cost of $465M. Just 3% more than the $451M budget of April 1999, or an increase of $14M.

Non-cost/schedule performance

As it turned out, the three non-cost/schedule key performance indicators placed tremendous additional, unexpected pressures on the alliance. On a project already under extreme time and cost pressures, none of the criteria covering safety, community, and the environment could be glossed over in the interests of expediency or cost. Performance measures for safety were set at 92% on process benchmarks and 8% on outcome in efforts to achieve a good outcome as a result of sustained effort rather than chance. Unfortunately, a fatal accident in the first 600m of tunnelling underlined the fact that the establishment phase of a new project is critical in terms of safety risk. As the project progressed, the incident rate in the worst week was 45.7. This compares with a 45.6 average for the construction industry in Australia. The project also achieved a measure for 'average weeks lost per 'lost time' injury' of 4.6 weeks, compared to 11.6 weeks for the Australian construction industry. Of a possible 20, the alliance scored 19.1 for safety.

Managing community affairs was a major challenge, with concerns centring on the project impact on property values, health risks raised by gases released at vent shafts, the visual impact of construction sites and shaft structures, and the noise and vibration created. In addition, the EIS - concluded before set-up of the alliance - led to some unmet expectations by the community, which elevated risk above that anticipated. With no precedent for benchmarking performance in community affairs, the same approach as for safety was adopted, with 12 elements of community process activities comprising 71% of the overall assessment and five outcome measures making up the balance. At 15.4 of a possible 20, the score was the lowest of the non-cost/schedule areas. However, by the end of the project the team was achieving scores of 18.25 through effective management systems, news broadcasts, and local consultations.

The environment was a complex area to manage, but more straightforward in terms of performance. Performance in this category was based on an Environmental Management System developed by the alliance that comprised 37 environmental management plans and judged against six measures relating to outcome, including the ultimate goal of cleaner water in the Harbour, and one measure relating to process. Risks were associated particularly with the complex environmental issues surrounding the project and the very prescriptive nature of the initial EIS. Eight modifications of the EIS were needed, and in total the team had to comply with 550 environmental conditions. Of 125 environmental studies commissioned during the project, 54 related to the natural environment while the remainder related to community impacts. Final score for the environment category was 17.3 of a possible 20.

At the end of the alliance partnership, and of a potential $2.4M available in bonuses for these non cost/time categories, the alliance amassed $1.8M.

Final analysis

The financial and timeline outcome of the Northside Storage Tunnel Alliance demonstrates the ability of the alliance process to minimise cost overruns and mitigate delays. In hindsight, however, all agree that the uncertainty and risk involved was significantly higher than anticipated. Alliance partners have also confirmed that reward or profit was lower than might have been expected through normal business practice.

Through the course of the alliance, various reactions to the experience were recorded. There were both positive and negative reactions by staff members to the management model. Several early members of staff found this management style too radical and left, while many others are reported as saying they were not looking forward to going back to the confrontational 'business as usual' climate of the construction sector4.

That is not to say the team avoided disagreement entirely. There were said to be some tense and frank meetings on occasion. However, since each alliance partner was sharing in project profit or loss, there was no room for vested interest, and tension was often diffused under the 'no-blame' policy. A most significant success of the alliance was that, although excavation delays and additional works due to adverse ground conditions were considerable, no time was lost through contractual argument. Emphasis on the sharing of risk by all alliance partners ensured that getting through these difficult zones and making design changes quickly, efficiently, and as safely as possible limited consequential increased cost impacts.

The greatest challenge for the alliance was in management of community affairs. The fact that the alliance's performance in community management had an impact on its bottom line empowered community opposition. It was realised too late that the community had substantial power but was not a formal part of the project process and so had no responsibility within the parameters of the project. This 'power without responsibility' skewed dialogue in the community's favour and created unexpected risks for the project team. Under a conventional contract, the most significant opposition, raised at one of the sites where an exhaust vent became the focus of health concerns, may have driven the contractor from the site and would have led to major claims. Under the alliance, partners had the flexibility to deal with this issue, even at its most confrontational.

A significant lesson learned was that it is much more difficult to regain community trust once it has been lost than capture and maintain it from the outset. "We were not ready for the level of community hostility," said Henderson. "We seriously underestimated the resources needed to manage this aspect of the project." A formal mechanism for community response and participation, with perhaps a representative body signing up as a full member of the alliance, would need to be examined for future alliance projects in urban environments.

The greatest achievement, however, has to be the completion of more than 20km of tunnel in a contract period of two years and nine months, to within 3% of the final $451M budget. Given the obstacles faced by the alliance, this is an outstanding result. But no matter the degree of success, there are those who will find fault and attempt to make political capital by criticising any hint of cost overruns. In the Auditor General's Report to State Parliament in 2001 concerning Sydney Water's financial year ending June 2001, a section does state that the costs of the Northside Storage Tunnel project to date "are $467M," but that "final costs are unknown as some assets need to be sold and insurance claims finalised." It also states that the "final budget was $451M, and the original estimate was $375M," but does not explain the circumstances under which the original estimate was calculated. As it is, the 3% increase on the final budget amounts to the $465M stated in the project closing account.

Despite media detractions, senior representatives of the three main parties involved on the day-to-day management of the alliance are satisfied with the outcome, and each has said that they would work again on an alliance project. Allen Henderson of Sydney Water said: "The Northside Storage Tunnel Alliance provided an opportunity for Sydney Water and its partners to learn much about this form of project delivery. Valuable lessons were learned and these have been published in a booklet that is available as a reference. In fact, Sydney Water is already making significant use of this experience on several current major projects."

Charles Rottier, Director of Major Projects Asia for MWH and Alliance Director in 2000, said "this alliance gave the design teams unprecedented opportunity to work closely with the constructors during the design development phase and to resolve issues during construction. The alliance allows all parties, including the owner, to focus on solving issues and finding improvements without the traditional contractual demarcations and concerns. And all this done in a way that keeps control with the owner."

Transfield's Tunnelling Executive General Manager, Peter Kessler, commented that "the sustained commitment by all participant organisations delivered Australia a tremendous example of what relationship contracting can achieve." He went on, however, to say that "the project at times was benchmarked unfairly against the early cost estimates. Had the development of the original budget included adequate allowance for likely geotechnical and major urban infrastructure risks, the project's financial performance would have been better appreciated by external stakeholders."

Project References

- 1. Stewart Clegg, Tyrone Pitsis, Thekla Rura-Polley. Constructing the Olympic Dream: Managing Innovation Through the Future Perfect. Organization Studies Journal, publisher Walter D Gruyter

- 2. Stewart Clegg, Tyrone Pitsis and Thekla RuraPolley, 2002. Institutionalising Alliances in Construction Projects. Conference on Innovative Research in Management, Stockholm May 2002

TunnelTalk References

- Northside 'alliance' for cleaner Sydney Harbour - TunnelTalk, March 1999

- Sydney's alliance holding up under pressure - TunnelTalk, May 2000

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.