Testing durability of PVC membranes 04 Oct 2018

PVC-based polymeric membranes have been used for waterproofing tunnels for half a century. These membranes are subject to mechanical stresses during construction and to various impacts during their service life, including deformations caused by rock and tunnel wall movements, high temperatures and chemically aggressive water. The influence of these factors on the service life of membranes is determined by material testing in a laboratory using accelerated ageing procedures.

As the waterproofing layer is an inner layer of the tunnel construction, access to this layer is often not feasible and long-term performance data for these membranes are very rare. It was therefore a highly valued opportunity when two road tunnels in Switzerland with more than 40 years of uninterrupted service were selected for maintenance work. The installation of emergency exits required crosscuts in the tunnel construction that allowed samples of the 41 and 44-year-old PVC membranes to be obtained.

Tunnel Reussport

The Tunnel Reussport is part of the highway bypass of the city of Lucerne in the centre of Switzerland. It is a 600m-long mined tunnel and consists of twin tubes with three lanes each.

Built in 1970 in the partial waterproofing style with water drainage along the tunnel sides but no bottom waterproofing (Fig 1), it has a single-ply membrane made of PVC-P with a glass fleece inlay. Thickness of the membrane was originally 1.5mm.

At the start of the refurbishment project in 2009, waterproofing membrane samples were excavated during boring of the crosscuts and sent to Sika for testing against a sample of the original membrane produced in 1970.

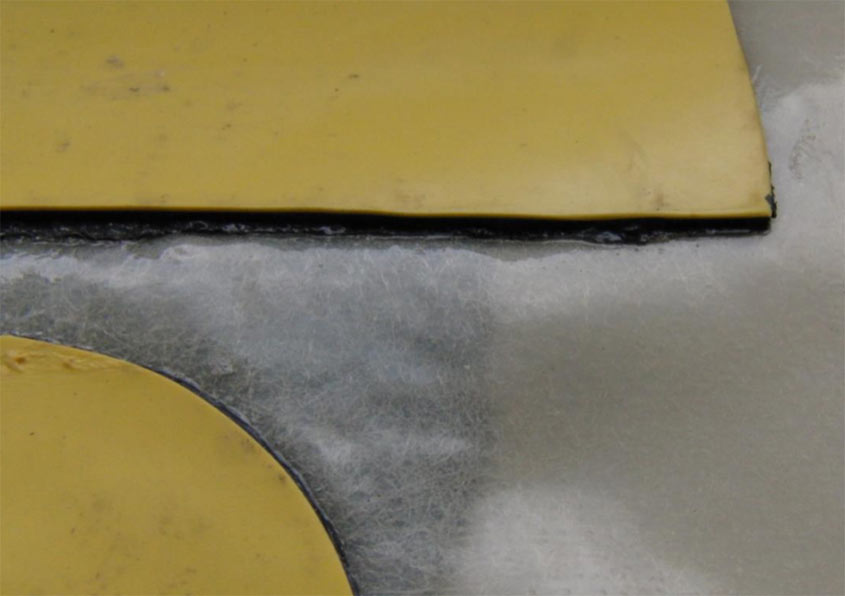

Aside from fresh scratches and holes caused by the excavation procedure and some stone indentations found on the bottom side of the membrane, the pieces were in very good condition with surprisingly good flexibility. They contained traces of adhering concrete on the backside, so areas with low concrete residues were used for testing purposes and the residual concrete was removed.

Tunnel Allmend

The Tunnel Allmend in Thun is part of the A8 highway that connects the cities of Berne and Lucerne. Built in 1968 as an open-cut tunnel, it is a 960m-long twin-tube tunnel that underpasses a military training ground.

Despite refurbishment in 1991, the tunnel’s 44-year service life left it partially damaged and requiring renovation and new security installations (ASTRA).

The waterproofing membrane is single-ply PVC-P reinforced with a fine polyester mesh. In 2012, during the planning phase of the refurbishment project, six samples were taken. They appeared undamaged and highly flexible. They were sent to Sika, where they were tested against retained samples of the original 1968 membrane.

Reussport samples exhibited scratches and holes caused by excavation equipment, as well stone indentations and concrete residue

Testing and results

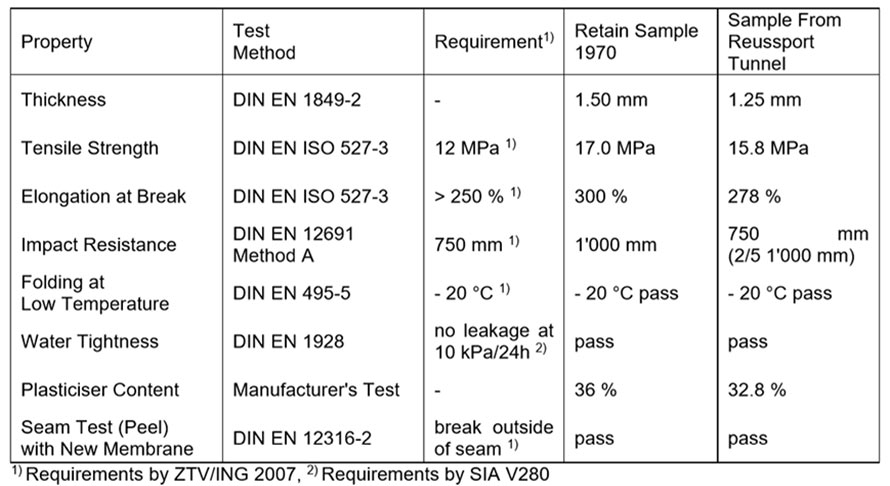

Material samples were tested at Sika's R&D centre and at the laboratories of the University of Applied Sciences in Cologne, Germany, with test methods based on European standard procedures. The relevant properties examined were:

- thickness

- tensile properties (strength and elongation at break)

- low temperature flexibility

- resistance to mechanical impact

- residual plasticiser content

- water tightness

- ability to weld to a new membrane

Detailed test results are presented in Tables 1 and 2.

Water tightness, the most important membrane property, was perfectly maintained as proven by the 24hr slit pressure method T, in which test all samples passed without any leakage or pressure drop.

The tensile strength of both membranes remained above the ZTV/ING requirement for new products. The elongation at the break was slightly decreased, with the Reussport material still surpassing the initial requirement. The inlay of thin polyester fibres in the Allmend membrane placed its elongation at the break slightly below the requirement. However, the reduction of this property by 6% after 44 years of exposure is negligible.

Impact strength of a membrane is vital in the construction phase. The waterproofing membrane samples from both tunnels met the required impact strength level for virgin material.

Degradation of the material properties of PVC membranes is caused mainly by a loss of plasticiser. The plasticiser content of the samples decreased between 9% and 14% compared to the retained samples, which parallels thickness reduction. This decrease in plasticiser did not significantly affect the flexibility of the material. The aged samples passed the requirement of sharp bending without cracking at -20°C.

By experience the plasticiser loss curve is exponential, meaning that loss is highest in the first years and slows down in subsequent years (Fig 2), so presumably these membranes will fulfill their function for several more decades. A sound prediction of residual service life would require data from various points in time, and unfortunately such data usually are not available for tunnels.

Potential for welding to new membranes was tested by hot-air welding samples of the PVC membranes from the two tunnels to fresh membrane pieces available on the market. After cooling, the strength of the seam was tested by peeling. The criterion of a good bond is that the break occurs outside, not within, the seam.

For samples from both tunnels, the peeling tests resulted in breaking of the pieces outside the seams. This proves that joining the old membranes with new ones will produce strong, watertight seams, and waterproofing additional crosscuts in the tunnels during renovations should be easy.

Fig 3. Comparison of lab testing (simulation) with actual 41-year-old samples taken from Tunnel Reussport (validation)

Good as new

After more than 40 years in real-life tunnel application, these membranes still largely fulfil German and Swiss standard requirements for virgin tunnel membranes and surpass expectations (Fig 3). Unlike other material classes that show rapid decay after long phases of almost no deterioration, PVC membranes deteriorate the fastest in the first years of application. This initial deterioration is followed by an exponential slow down.

Based on this exponential slowing of degradation, it is likely that these membranes can reach the expected 100-year service life. Therefore, replacement of the PVC waterproofing membranes in both tunnel renovations was deemed unnecessary.

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.