Hydroelectric waterway inspections 12 Mar 2020

Headrace tunnels of many hydroelectric plants are rapidly increasing in age beyond 40 years. While routine maintenance and upgrades or repairs can be performed during short outages, more effort is required for longer outages for inspections and maintenance access constraints.

Many ageing hydroelectric tunnels have experienced serious problems, including some collapses, due to their extended age and the absence of maintenance and repairs. New hydroelectric tunnels are also required to be inspected after a period of initial operations in order to confirm the adequacy of their original design.

Without appropriate inspections and maintenance the ageing of hydroelectric tunnels can be expected to result in additional partial blockages and full-scale collapses. Ageing hydroelectric tunnels are also associated with risks of poor environmental compliance since tunnel collapses can result in the complete stoppage of flows for downstream ecosystems or can require excessive releases from the intake structure, which may cause significant erosion or scouring or flooding of vulnerable areas.

Consequences of problems

The structural integrity of hydroelectric tunnels is of paramount importance to safeguard long-term operations for the generation of power. The occurrence of partial or full collapses in hydroelectric tunnels poses serious risks for overall operations and typically results in extended shutdowns for major repairs.

Similar to other engineering infrastructure, hydroelectric tunnels have a finite life of integrity, and maintenance and repairs should be included as part of normal operations. While some hydroelectric tunnels continue to operate without problems after several decades, the life of most tunnels is finite and serious problems can be expected after 30 to 40 years.

The greatest risk posed to the safe long-term operations of hydroelectric tunnels is the stability at the locations of geological faults or other weak geological conditions as encountered during construction. Collapses that have occurred during commissioning have occurred because of inadequate support of geological faults and the non-recognition of non-durable or scour-susceptible rock conditions. Geological fault zones supported with shotcrete alone for long-term operations can be subjected to scour and deterioration.

The condition of rock traps is to be confirmed during an inspection to ensure they have capacity to prevent debris passing over the rock trap and into the causing serious damage.

Inspections for ageing facilities

A first inspection of older installations is typically performed as a result of a detected or inferred problem after many years of operations. The most important aspects to be considered are the hydraulic operations and the occurrence of historical problems. Hydroelectric tunnels operated under peaking conditions are subjected to highly variable internal operating pressures with associated cyclic loading of the support and linings. This is because of the termination and re-start of operations for peaking operations which are therefore more susceptible to damage during long-term operations and warrant a higher frequency of tunnel inspections.

Advances in robotic and data acquisition technologies with remote operated vehicles (ROVs) are able to capture additional information and of improved quality to perform more comprehensive condition assessments. Unwatered inspections of hydroelectric tunnels are the preferred type of inspection whenever possible in order to prevent causing possible damage to an existing tunnel. Unwatered tunnel inspections using remote operated vehicles (ROVs) are typically performed. Unwatered ROV inspections can also be performed during very low velocity conditions if necessary, to maintain some limited power generation.

A dewatered inspection should only be considered in the event that the findings of an unwatered ROV inspection indicate serious concerns, such as large volumes of debris, large fallouts, the occurrence of substantial leakage, or noticed headlosses. Dewatering for manual inspections can be expected to impose risks by causing additional instabilities. Dewatering needs to be performed in a controlled and slow manner to limit instability. Drones can also be used for a preliminary manual inspection if suspect or unstable areas may be present.

Unwatered inspections

ROVs are typically tethered for the inspection of long hydroelectric tunnels to provide power and for the transfer of the collected survey data. The manoeuvrability of ROVs enables them to access complex geometries of surge shafts and intake gate slots to enter long hydroelectric tunnels. The longest single pass ROV inspection was 12km at the Snowy Mountain scheme in Australia and the longest total inspection completed was for the 120km Paijanne drinking water supply tunnel for Helsinki, Finland. ROVs have operated at depths of more than 600m and some are capable of operating up to 2,000m.

In low turbidity clear water ROVs can provide high-resolution photographs and video imagery. In high turbidity conditions, profiling sonars are used to provide continuous 360° data for a high-resolution 3D point cloud model and associated visualisations. ROV contractors have also developed and used visualisation software to aid in the observations during an inspection.This allows for immediate identification of locations of interest where debris may be present along a tunnel.

Part of the overall condition assessment of aged linings is to detect if there is any deterioration or void forming. To date there does not exist any standard approaches for the investigation and inspection of the integrity of shotcrete, concrete or steel tunnel linings or the presence of voids behind linings. The use of modified forms of ground penetrating radar, seismic reflection and acoustic emission techniques may be developed in the future to be used with an ROV inspection to provide this crucial category of information.

Manual inspections

Dewatered inspections benefit from having direct access for detailed observations and identification of possible defects, scour and debris. Another important benefit is that samples can be obtained from shotcrete and concrete lining sections and tested for durability and strength.

One of the greatest uncertainties with concrete linings within ageing waterways is the integrity of wooden beams used commonly used to support historic excavations. Over time these rot and result in the formation of voids behind the lining.

Methods of manual inspections include:

- Visual observations

- Strength testing

- Sonic and ultrasonic methods

- Magnetic methods

- Electrical methods

- Thermography methods

- Radar methods

- Radiography methods, and

- Endoscopy methods

Robotic technologies for use in manual inspections include:

- Photogrammetry methods

- Impact methods

- Laser methods, and

- Drilling methods

Technological advances are also being developed for new and hybrid methods to provide additional information during manual inspections(1).

Evaluation of observational data

The presence of erosion and debris along a waterway represents important information about its condition and performance. If present along the tunnel crown they may manifest into an instability or with the fall out of rock blocks or a large-scale collapse with partial or total blockage of the waterway. Comparisons with previous inspections will identify increases in the volumes of erosion and debris after ongoing operations.

The conditions of concrete and shotcrete linings are typically of most interest. Numerous 3D visualisations prepared from the inspection data will identify the geometry of the transitions in linings where scour can occur and create significant changes in the geometry of the profile.

Asset risk assessment

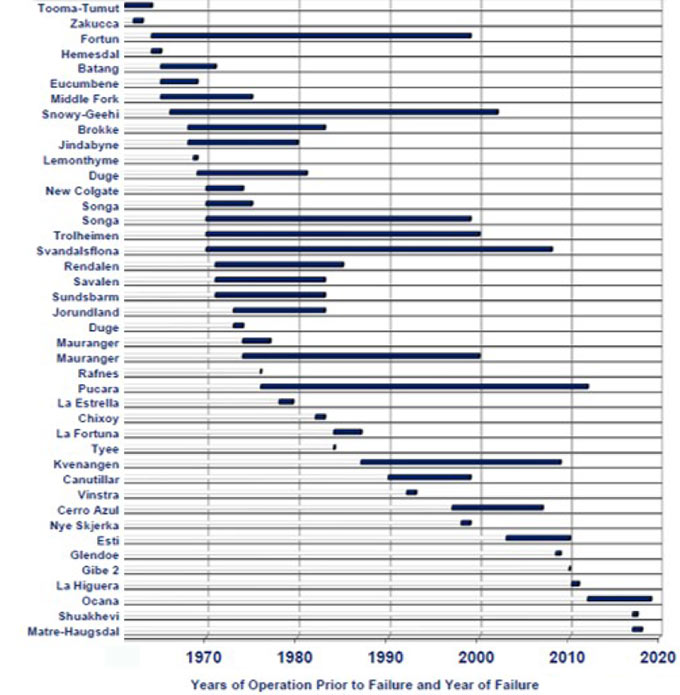

The risk assessment for a hydroelectric waterway represents a complex engineering challenge and are based on the age, hydraulic operations, and linings (Fig 3).

Following the completion of an inspection, an updated or new risk assessment should be performed with both qualitative and quantitative risk assessments completed. A qualitative risk assessment are based on historical and recent inspection observations, historical problems including leakage failures or instabilities, and historical and normal hydraulic operations(2).

A quantitative risk evaluation should be based on optimistic and pessimistic assumptions in order to provide an indication of the remaining life of the tunnel before a major collapse(5). One assessment approach is based on accumulating the probabilities of failures due to identified instability or failure mechanisms that are deemed plausible based on consideration of:

- Tunnel and shaft history, geology, and the support and lining installed during original construction;

- Information from previous inspection reports and repairs;

- Identification of areas of problems or risks based on inspection information, and;

- Review of case histories of other hydropower failures in similar geology.

A method to calculate an annualised probability of a tunnel collapse, PA is defined as PA=Pe x(NRSxPC) where

- Pe is the annual probability of an initiating event,

- NRS is the number of risk sites or locations where failure is deemed to be possible, and

- PC is the conditional probability of failure at each of the risk sites.

The selected NRS values for the risk assessment should be based on consideration of the number of unlined and concrete lined sections along the tunnel, the number of historical occurrences of instabilities, and the number of available rock traps. A quantitative risk assessment can provide estimates of the remaining life of a hydroelectric tunnel before a major collapse, which is important information for future planning, maintenance and repairs. A formal risk workshop with hydroelectric engineering experts is recommended to perform a comprehensive risk assessment.

Author References

- Montero, R., Victores, J.G., Martínez, S., Jardón, A., and Balaguer, C. 2015. Past, Present and Future of Robotic Tunnel Inspection. Automation in Construction, Elsevier.

- Rothfuss, B.D., Bednar, S., and Clarke, E. 2011. Water Tunnel Condition Assessment: A Comprehensive Approach to Evaluating Reliability, Hydrovision, Sacramento, CA.

- Fippen, R., Sketchley, J., Redhorse, T., and Tsztoo, D. 2018. In‐Depth Inspection of a Century‐Old San Francisco Water Tunnel, North American Tunnel Conference, Washington, DC.

- Jessop, M., Jardani, A., Revil, A., and Kofoed, V. 2018. Magnetometric resistivity: a new approach and its application to the detection of preferential flow paths in mine waste rock dumps. Geophys. J. Int. (2018) 215, 222–239.

- Rosen, S. 2005. Geotechnical Risk Assessment and Management for Maintenance of Water Conveyance Tunnels in South Eastern Australia. AGS‐AUCTA Mini‐Symposium: Geotechnical Aspects of Tunneling for Infrastructure Projects.

References

- Hydro TBM risk assessment and selection – TunnelTalk, March 2020

- Rock falls shut down Glendoe power plant – TunnelTalk, August 2009

- Man-entry inspection of Drakensburg penstock – TunnelTalk, August 1992

- Urgent infrastructure needs in Nepal – TunnelTalk, November 2018

- Tough excavation for clean energy in Georgia – TunnelTalk, May 2017

- New award follows Kishanganga success – TunnelTalk, May 2014

- Europe hydro vision needs 165km of tunnels – TunnelTalk, November 2012

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.