When boring a tunnel, homogeneous hard rock is often the exception rather than the rule. While contractors can set goals such as meterage per month and performance incentives, it is also prudent to plan for difficult ground, and to have a Plan A, B, and C depending on the conditions encountered. Of course, Plan A can be to assume homogenous rock connects the launch point and the breakthrough point, and that you will be able to tunnel while keeping your TBM moving and keeping your crew safe. This is not the case, however, for the majority of tunnels.

So what is a more realistic Plan A? It is planning ahead. The parties involved must invest in enough geological testing for the risks to be reasonably and accurately gauged. Once the risks have been assessed, they can be mitigated, with a properly designed machine equipped with technology that can tackle fault zones, water inflows, squeezing ground, or whatever the predetermined risks may be.

The alternative, to modify the machine in the tunnel after bad ground is encountered, is not a good one. Not only does this result in increased downtime, but it also can needlessly expose your crew to additional risks. In the worst case scenario, the entire operation grinds to a halt. We would like to argue that, in all but the most extreme of cases, this should not be happening in today’s tunneling world. We have the modern technology to prevent these situations.

To plan for potential challenges adequately, the risks must be understood. It seems a simple statement, but all too often owners tend to skimp on geological surveys due to perceived unnecessary up-front costs versus benefits.

We have been involved in many tunnel projects where core samples are only taken every few kilometers. These samples can indicate a fairly uniform tunnel, but what happens in between those samples is anyone’s guess. Such surveys can and have missed major fault zones, voids, and other features that can, and have, resulted in major project delays. The cost of having a stuck or damaged machine in the tunnel for months, or even years, is much higher than the initial cost of adequate geotechnical studies. If such surveys can be done, then the machine can be designed specifically to deal with any known features along the tunnel length, thus optimizing excavation rates.

In most cases, a meter-by-meter or even kilometer-by-kilometer geotechnical report is not possible logistically or feasible economically. This is the case when excavating high cover, mountainous tunnels in regions such as the Andes, the Himalayas, and the Alps. Pre-construction investigations are typically limited to desk studies and surface mapping, however, access for mapping investigations may be further limited by the need for safe landing locations when using helicopters for the surface survey.

Simply put, those involved in high cover, mountainous projects must accept a higher level of uncertainty. This can mean having in place appropriate contingencies for additional costs and delays if difficult conditions are encountered. Selection of a TBM type, whether an open machine, a standard shielded machine, or a shielded TBM capable of holding pressure, will depend on the geology, the tunnel lining specifications, and a variety of factors, but all three types of machines can successfully bore in difficult ground.

Contractors and owners taking on unknown risks in mountainous tunnels can outfit a shielded TBM with a range of difficult ground solutions. Design options can include:

If a TBM is equipped with these features from the start, then costly downtime and in-tunnel machine modifications can be avoided. Shielded machines have the beneficial advantage of providing support and safety within the machine itself. If a concrete segmental lining is needed, double shield and single shield machines bore and erect the tunnel lining.

In even the most extreme ground conditions, main beam TBMs (also known as open-type machines) can be efficient and safe. Features such as open access behind the cutterhead for ground support and consolidation, unrestricted probe drilling, and the absence of a shield are all-important attributes of open machines in extreme conditions.

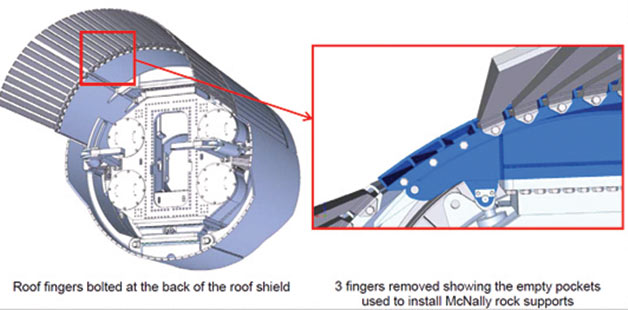

In ground exhibiting squeezing-convergence and rock bursting, open-type machines often fare better than shielded machines, as they are less likely to become trapped or stuck. They can also utilize the McNally Support System, which can, in essence, be made to function like a shield. In swelling or slacking ground main beam TBMs also allow for immediate ground treatment behind or over the top of the cutterhead. Open-type machines are capable of operating in ground with occasional to continuous water inflow, as long as mitigation strategies, such as combining injection grouting to stem flows, and sufficient pumps to remove the water, are employed.

For squeezing or converging ground, over-boring is frequently recommended. In practice it is seldom used effectively. However, it is still a viable option if properly employed. Over-boring is typically applied by pre-mounting extra gage housings in the periphery of the cutterhead. In the over-bore zone, yielding type support structures should be erected if using an open-type machine. These elements can include yielding steel arches, steel arches in conjunction with yielding jacks, shotcrete structures with yielding rock anchors, or combinations of the above. Arch supports need to be placed with assistance of the ring beam erector or some other mechanical means. The most desirable location to place this support is immediately behind the cutterhead, which is a problematic situation with a shield type machine. The machines also must be equipped with high torque to overcome the loading on the cutterhead of a collapsing face.

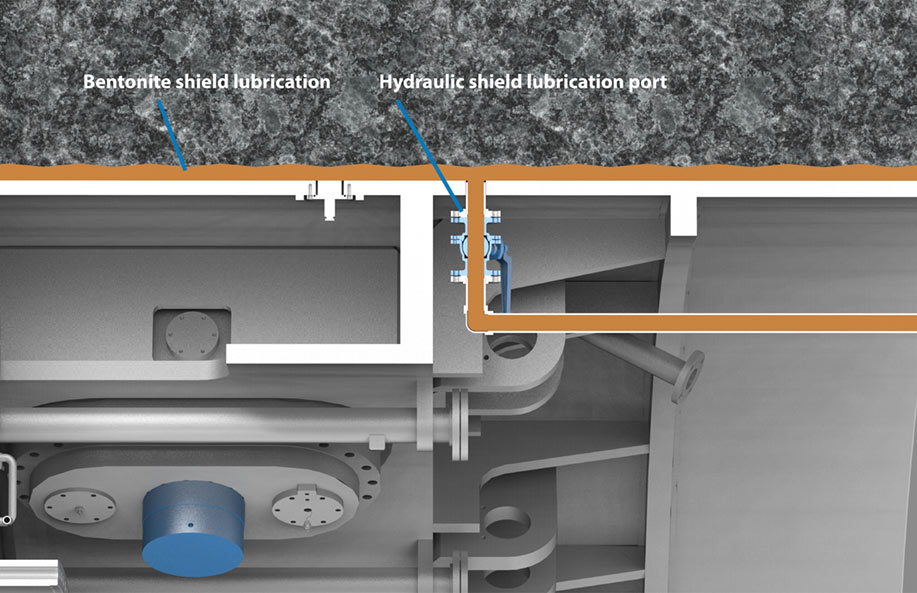

If using a shielded machine and erecting a segmental lining, there are systems now for detecting when squeezing conditions are present. One such feature is a convergence measuring system that comprises a hydraulic cylinder mounted on top of the machine and connected to the machine’s PLC. Having a machine designed with the shortest possible shield length, and a stepped or tapered shield if necessary can be immensely helpful. As mentioned previously, shield lubrication and emergency thrust can get a machine through a situation where it might otherwise become trapped.

In rock bursting conditions wire mesh with rock bolts, yielding rock anchors, steel arches, ring beams, or combinations of all of the above may be required. Such support can be placed with rock drills, a ring beam erector, and a shotcrete system. It is important to hold the rock in place to control and limit the disturbance of the rock to as great an extent as possible. With modern open-type TBMs, ground support such as the McNally roof support system allows support to be extruded from the machine as it advances. This is a very safe option in these conditions. Today’s TBMs are also equipped with all of the same tools and techniques that are used in drill+blast operations to excavate through difficult rock conditions. On a shielded machine, probe drilling is as important as it is on open-type TBMs. In all conditions, advance probe drilling is recommended 30m to 40m in advance of the face with a 10m overlay. The machine’s shield provides safety against rock bursting events.

An effective ground treatment in swelling and slacking conditions can be shotcrete applied immediately behind the cutterhead, which is only possible with open main beam gripper TBMs. In extreme conditions, over-boring may be required and measures for rock support in squeezing ground may be needed. The support can be a combination of tools applied using shotcrete units, rock drills and ring beams on an open-type machine. The difficult question, however, is how to predict the extent of swelling and squeezing of the rock. This is a very important consideration when considering the use of concrete segments in such conditions. Because of the difficulty of predicting the extent of swelling, two-pass lining systems have been used such as in the large diameter Niagara water diversion tunnel project in Ontario Canada. This large 14.4m diameter tunnel through sedimentary rock used initial ground support followed by a waterproof membrane and a final cast-in-place concrete lining.

Fault zones can be the most difficult condition to encounter, especially when associated with water under pressure. They are also among the most difficult of conditions when attempting to predict expected advance rates.

Probe drilling is especially important when fault zones or water ingress are expected. When a probe hole predicts a fault zone or water ingress ahead of the face, the extent of the zone should be explored thoroughly prior to advancing the TBM to within 10m-20m of the zone. To start, further probes should be drilled on a 360-degree basis. The zone should then be grouted to stem water inflows. After grouting, ground consolidation additives should be injected into the unstable rock or soil material. It may be necessary to inject such material into the face at short intervals of 2m to 4m, and advance at shorter intervals. The support of geologists and ground conditioning experts experienced in predicting and treating fault zones is highly recommended when fault zones are encountered.

For passing through fault zones, grout and ground conditioning holes are required. After ground treatment, ground support such as spiling or forepoling through the front shield and over the cutterhead may be necessary for safe and predictable advance. It is preferable to carry out this drilling as close to the face as possible to ensure good face coverage. These methods are all possible when using an open-type or a shielded type machine.

When water is present in a hard rock tunnel, it can be pumped away from the face and out of the tunnel (even fairly significant water inflows). However if there is a possibility of significant pressures and/or a massive inrush of water, then a shielded machine with sealable to high water pressures is recommended. In the event of a large inrush of water, a guillotine gate on the muck chute can effectively seal off the muck chamber to keep the crew safe and the machine protected from becoming flooded. On a shielded TBM, additional inflatable seals can be installed to seal the gap between the fort and rear shield cans. These, together with tail seals and a gasketed concrete segmental lining, can keep the everything watertight. This system is termed ‘passive’ water protection because the TBM is stopped in place (not actively operating). During that time the crew can then work to grout off water inflows and dewater the chamber to control the flow before they begin boring again.

In blocky or highly jointed rock, the McNally system to hold the rock in place has been proven on many projects as being very effective in open-type machines. If the rocks are held in place then this can prevent or lessen the condition of cathedralling over the cutterhead and fallout in front of the face. It also reduces damage to the cutterhead. The ground support should be placed as close as possible to the cutterhead. Horizontal rock supports for the McNally system can be prefabricated rebar, wood/metal slats, or wire mesh in conjunction with straps, rock bolts and/or steel sets. In a shielded machine, features to navigate blocky rock successfully include shield lubrication and tapered shields. Another system, termed hydraulic shield breakout, injects pressurized hydraulic lubricants through radial ports in the TBM shield to free a shield that has become stuck. All are useful techniques.

Ultimately whether using an open-type, main beam TBM or a shielded hard rock TBM, challenging ground requires a close working relationship with the contractor and the TBM supplier. Utilizing well-trained operators and an experienced crew can make all the difference in a project’s success. Moreover, all parties must be willing to accept that certain unknowns may require changes in boring protocol, ground support, or even modifications to the machine in the tunnel. Having plans in place for each type of ground condition, whether expected or unexpected, can go a long way in minimizing downtime should such features be encountered.

Stuck TBMs are most often avoidable. They tend to be the confluence of several factors: difficult geology, inaccurate or insufficient geological investigation, non-customized TBM design, or lack of contingency planning. With all the tools at our disposal for modern tunneling projects, stuck TBMs should be a thing of the past. Difficult ground solutions, probe drilling, and other features such as technology for measurement while drilling and tools such as tunnel seismic prediction units, arm contractors with a look at what is ahead, as long as they are willing to take the time to do it systematically and thoroughly.

These tools are increasing our visualization. We can now obtain a good idea of what is around the TBM in a 360-degree radius, and with a machine that is designed accurately and operated by a knowledgeable crew, we believe that TBMs can keep moving forward even in the most extreme of circumstances. It is clear that TBM technology is moving forward at a faster rate than conventional non-TBM technology, and mechanized full-face boring offers efficient and safe excavation.

|

|

|

|

|