As engineer of record for the Rio Piedras Station stacked drift project in Puerto Rico, Victor Romero of McMillen Jacobs Associates provides reflection on the experience and advice for others considering application of the technique on new projects.

Read the contribution on the Feedback page and at the bottom of the article, and contribute to the discussions via the Feedback facility.

Large diameter caverns for the Euston terminus station in London for the HS2 highspeed rail project in the UK is the latest project planned to adopt the stacked drift method of presupport. Seven interlocking smaller diameter headings around the profile of the caverns will provide the presupport and security for excavation of the core to create the station under the existing surface rail Euston Station, which must remain operational during the full construction period of the new HS2 infrastructure (Fig 1).

Publication of the plan in an interview article with HS2 engineers by TunnelTalk reporter Jonathan Rowland opened the discussion of where and how the stacked drift method has been used in the past and how their applications differ from the proposed application at Euston.(1)

One of the first well-recorded applications of the method was for the Mount Baker Ridge highway tunnel in Seattle, Washington, USA. The story goes that planning application for the short 1,500ft long (460m) underground route at shallow depth beneath the homes and urban infrastructure of the area above was being problematic. There was objection to the project in general and of the proposed multi-tube design for the four traffic lanes plus provision for a future light rail connection through the tunnel and across the Lake Washington highway bridge onto Mercer Island, a project that is now being finalised as the East Link of the Sound Transit LRT system.(2) A proviso that all be accommodated in one single tube, and that a pedestrian and cycle way be included as well, would kill off the project, resulted instead in a stacked drift design to create that single tube solution (Fig 2).

In an outstanding design and construction operation, 24 x 9.5ft diameter x 1,332ft long shield driven drifts were excavated to permit excavation of the impressive 63.5ft diameter interior space within which the four lane highway, the now the two tracks of the East Link LRT line, and the pedestrian and cycle ways in the upper levels, have been built and have been operating since the underground infrastructure opened in 1988.(3,4)

The next application of the method was for the Río Piedras Station on the Tren Urbano project in Puerto Rico. Funded 30% by the USA Federal Transit Administration (FTA), Tren Urbano was one of five demonstration projects selected by the FTA in the 1990s to research application of the turnkey design-build procurement method to control costs and time overruns on FTA funded public transit projects. It was also an early application of NATM in the USA.

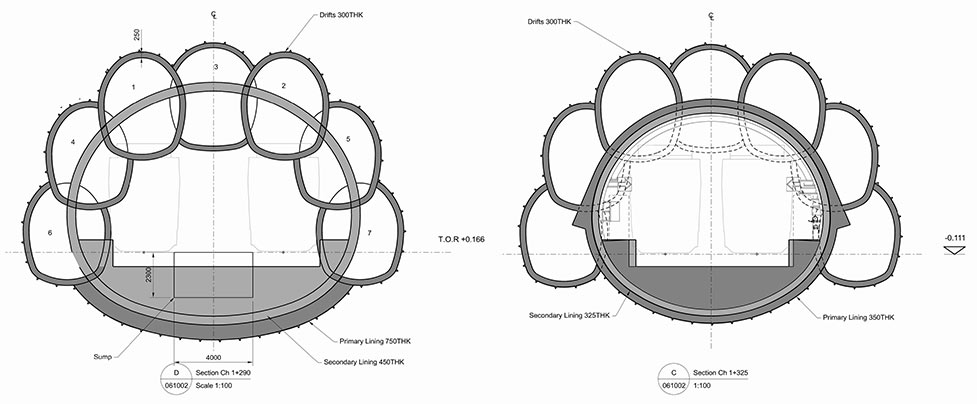

For Río Piedras, the Kiewit/Kenny/Zachry (KKZ) JV and its underground design engineer Jacobs Associates (now McMillen Jacobs) adopted the stacked drift method, after use of the method also by Kiewit for the Eisenhower highway tunnel through squeezing rock conditions in Colorado, USA. In Puerto Rico the design was needed to create the 240m2 Río Piedras Station cavern, at 17m wide x 17m high x 150m long, and under a shallow cover below the surface.(5)

The design comprised 15 interconnecting rectangular drifts of about 3m x 3m, excavated to the full 150m length of the station and back-filled with concrete to create a massive pre-installed lining for the core excavation (Fig 3). Compensation grouting by subcontractor Soletanche-Bachy was selected to limit settlement caused by excavation of the drifts.

Also in the 1990s, the method was applied to excavation of the undersea cavern for the crossover facility on the French side of the Channel Tunnel railway connection between the UK and France. A presupport of 11 contiguous headings of 170m long x 1.7m in dimension and 4.2m wide at the base was excavated ahead of core excavation to create a cavern of 20m wide at the base and 350m2 in cross section (Fig 4).(6)

An initial three drifts were excavated from access adits from the advancing TBM service tunnel drive and were back filled before the two 8.7m o.d. running tunnel TBMs reached the crossover at 12.5km under the Channel from the French coast. After passage of the running tunnel TBMs, work continued to excavate the remaining eight drifts to permit core excavation and breakout of the 7.6m i.d. segmentally lined TBM drives (Fig 4).

Another example of a presupport sequence is the method adopted for the Alonso Martinez and Tribunal Stations for the Madrid Metro in Spain (Fig 5).

Presupport using smaller diameter microtunnel excavations and the method of presupport pipe umbrellas and spiling are also well-established design concepts. Both have been used to successful effect to presupport and control poor ground conditions in the crown of open face excavations and to control the risks of surface settlement under shallow cover in critical situations.

A recent application of small diameter microtunnel presupport is for the twin tube railway underpass of a 21-lane highway in Toronto, Canada. The 180m long x 80m2 rail tunnels were presupported by a canopy of 13 x 813mm diameter steel pipes installed using an auger boring system to limit surface settlement on the operating highway above to 25mm maximum (Fig 6).(7)

The sequence of excavation for a stacked drift concept is a particular topic of debate and experience. Do you start with the lower drifts and work upwards, or start at the top and work down?

In Seattle, the sequence started in the bottom and advanced in a sequence using two custom built shields, one either side, to complete the joining drift number 24 in the crown.

In Puerto Rico, the design submitted for approval noted that the sequence would start with the two invert drifts and advance up either side to the crown. During excavation of the access shafts, it was considered that top down excavation of the drifts would be more convenient, but the change was not accepted by Tren Urbano. As a result, access ramps together with temporary backfill in the working shaft and decking was required to provide access for excavation the higher level drifts.

While the detailed design of the Euston Station stacked drift method is being developed at present, the concept illustration has the drifts numbered with the first in the crown, perhaps suggesting a top down sequence (Fig 1). TunnelTalk will publish further news as it becomes available.

Another concern in the stacked drift concept debate focuses on the control of settlement during the excavation of the drifts. Face loss will be experienced with excavation of the drifts and this settlement risk will require equal control and management ahead of core excavation.

A final consideration is the added cost of the presupport concept and the time needed to excavate and complete the system. The Euston Station drifts look quite large in size by comparison to the cavern excavations that they will presupport.

Once excavated, the drifts of the concept are backfilled with concrete ahead of core excavation. This adds time and cost to the application and as one commentator posted on the TunnelTalk LinkedIn post about the Euston Station stacked drift concept: “Buy one, get seven free”. Other comments on the LinkedIn post mentioned the application of the concept on other projects around the world and raised other points about the application in London including a note that other similar sized caverns have been excavated in London without the need for a presupport design. These include the crossover and Y junction caverns excavated at Stepney Green for the Crossrrail project in south London.(8)

The 17m high x 16.5m x 120m long cavern was designed and excavated as an SCL topheading, bench and invert sequence, dividing further into single and double side-wall drifts as the span of the Y junction cavern increased to its widest point. The Stepney Green caverns are largest excavated by SCL in the UK (other than the UK crossover chamber on the Channel Tunnel, which is slightly larger and also excavated as an SCL or NATM multi drift sequence). Both the Crossrail and the Channel Tunnel caverns were fully excavated before arrival and pull through of the running tunnel TBMs.

The stacked drift design being developed for the HS2 Euston Station caverns might well be considered part of the “gold-plating” of the project design that Doug Oakervee, as Chair of a panel of experts set up by the Government to undertake an independent review of the HS2 project, highlighted in its report.(9) The report noted that: “there has been considerable over-specification and gold-plating in HS2 contracts with much of the design seemingly done on a worst-case, risk-averse scenario”. To counter the comment, the excavation objective of the Euston Station caverns in particular is to assure the safety and security of the surface and adjacent underground infrastructure in the congested Euston area of the London.

Join the discucssion via the TunnelTalk Feedback and its comment facility and the Contact Us email address

and on LinkedIn.

Advice following stacked drift experience

Feedback from: Victor Romero, McMillen Jacobs Associates

Dear Editor,

I read the article with great interest. It is a nice summary and brought back a lot of memories as engineer of record for the Rio Piedras Station in Puerto Rico - some good, some not so good.

The good memories were all the great people I worked with at Kiewit, Soletanche, McMillen Jacobs and the owner, past and present, because it was a huge, challenging effort to implement the design and construction, and we were using the emerging technology of the late 1990s of compensation grouting, with real time settlement monitoring.

The not so good memories were mainly the poor ground, low cover conditions and leaking utilities that we faced. But we got there in the end.

One thing the article did not mention was there was another stacked drift going on at the same time for the underpinning of South Station on the Big Dig underground highway project in Boston. The project faced significant challenges there as well, but not as much was published, unfortunately, and there are other examples of application of the technique in Italy, I believe.

I occasionally get asked about the stacked drift method on some projects when in planning stage. Of course each project is different with respect to ground conditions, site constraints, and functionality of the finished structure, so sometimes, in very rare circumstances, a stacked drift may be a viable solution. But it is slow and costly, and new technologies mean we have other options to consider for very large diameter excavations.

In many cases SEM/NATM is viable, although application of many additional control measures in the toolbox may be needed. Settlement mitigation and monitoring measures have greatly improved. For longer tunnels, TBM segmentally lined excavations are pushing some amazing diameters now.

While I am happy to see others might be attempting the stacked drift method, my advice is to proceed with caution and make sure your design and construction methods are fully integrated. Yes, that is true for any tunnel project, but especially so when building a stacked drift project.

Regards,

Victor Romero, PE CPEng,

President - Underground Division,

McMillen Jacobs Associates

|

|

|

|

|