The study of aerodynamics in tunnels is crucial to determine the right levels of ventilation and air quality for passenger comfort. Air is renewed via ventilation shafts located at stations and throughout the tunnels as they draw air in either by train movement or mechanically.

Using a simulation software called Express Air, Setec tpi has carried out detailed aerodynamic studies on the south part of Line 15 on the Grand Paris Metro to see whether air flow is sufficient for passenger needs and what effect headway has on the need for extra mechanical ventilation.

A short train headway at this section of the line generates a periodical piston effect that means there is not adequate air circulation all along the tunnel. As trains are fully automatic and driverless, they are even more regular, which exacerbates the problem and so requires mechanical ventilation to be activated. The study found that a headway below 130 seconds is not able to provide enough fresh air in the tunnel and needs the intervention of mechanical ventilation.

The south part of Line 15 has 35km of double track tunnels, 16 underground stations (17 were simulated to cope with future tunnel extension), 51 Piston relief shafts including 31 mechanical ventilation shafts, and 3 connecting tunnels to the depot and other lines.

Express Air predicted transient gradients of different physical scales such as airflow velocity, pressure, temperature and polluting elements in tunnel environments such as road, railway and electrical lines.

The simulation considered different stabilized train timetables, filling the whole line, each with a different headway, and with fixed station dwell times. Five headways between trains were considered for the study - 90, 110, 167, 220, and 300 seconds. For each headway, different synchronizations between up way and down way trains were analysed.

Mechanical ventilation involves extracting air that by-passes inter-station piston relief shafts which supply fresh air. Air renewal requirement is calculated from the passenger occupancy of trains and French law defines the minimum fresh air needed for one person as 25m3 per hour.

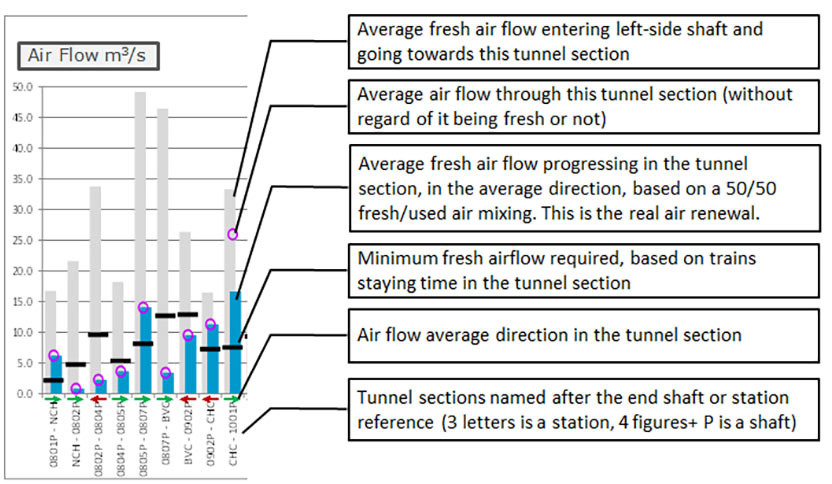

A fully loaded train can transport up to 1400 people and a train stopped at a station needs a continuous volume of at least 9.72m3/s of fresh air. As trains move along the tunnel, the required air renewal rate is calculated on the basis of the staying time within each tunnel section (defined as the tunnel extension between two piston relief shafts). The airflow movement inside the tunnels follows a similar pattern that repeats over time. The repetition period corresponds exactly to the train’s headway.

Average air flow velocity in the tunnel is about 0.8m/sec down main direction, then 0.7 m/sec up main direction, so air flow inside the tunnel section moves back and forth periodically covering only an average distance of about 40m every 90 seconds.

With an average airflow velocity through the tunnel section of 0.1m/sec it is obvious that the air renewal rate is not compatible with air quality requirements, despite the large amount of fresh air periodically drawn at the shafts and the air mixing thanks to the train movement.

Simulation tests carried out for different tunnel sections and timetables were inconclusive so a statistical approach using Express Air was used to determine the point at which mechanical ventilation was needed thus ensuring passenger air quality in all conditions of train operation.

Fig 3. shows that air renewal rate is more effective with piston relief shafts distributed between the stations and is also linked to train headway. During analysis the limits of the 1D model were accounted for and 3D phenomena, like turbulent air mixing around and downstream the train, were considered for their effects in helping ventilation.

It was concluded that if more than 80% of tunnel length is deemed adequately ventilated, then natural ventilation due to train movement is considered effective. If more than 20% of tunnel length is below fresh air renewal requirement then mechanical ventilation needs to be operated.

Pressure relief shafts between stations are helpful for natural ventilation due to train movement but mechanical ventilation needs to be used when the train headway is below 130 seconds.

|

|

|

|

|