Tight curve drive breakthrough in Bangkok 27 Jun 2019

The first of two EPBMs on the complex Chidlom cable tunnel project in Bangkok has celebrated a successful breakthrough. The 3.2m diameter Terratec machine completed a challenging portion of the project that included a tight 35m radius curved drive for contractor Italian-Thai Development.

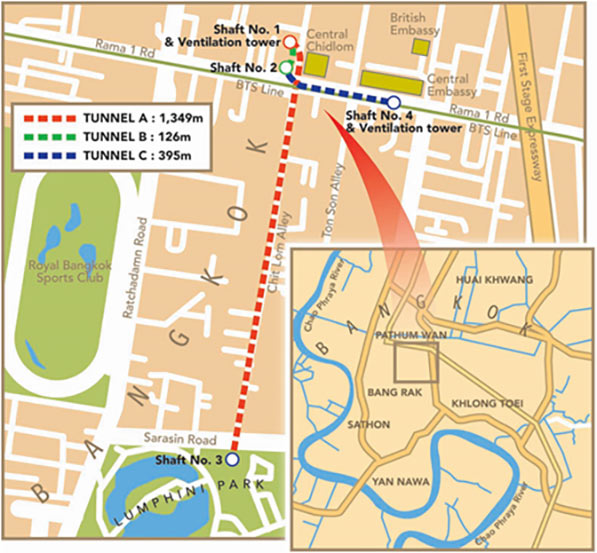

Running from the Central Embassy mega mall, located on Phloen Chit Road within the former gardens of the British Embassy site, southwards to Lumphini Park, the project for the Metropolitan Electricity Authority is located in one of the most exclusive and built up areas of downtown Bangkok (Fig 1). To remain within public road easements and negotiate building foundations and the deep piles of the Sukhumvit Skytrain that runs along Phloen Chit Road, the tunnel drive alignments are subject to strict constraints that require several tight radius curves to bring them into the Chidlom electical terminal station. To achieve this, the Terratec EPBMs have been designed with an X-type articulation system, which can accommodate very tight curves.

“We have worked closely with Terratec on several projects in the past and have had a close collaboration with the company from the tender stage of this project,” explained Project Manager Supak Khunviriya for Ital-Thai. “The TBMs are designed to achieve a high level of performance in difficult circumstances and the Terratec team has assisted us throughout the tunnelling operations.”

The soft ground TBM cutterheads feature an open spoke design with the addition of knife bits to assist break-in and break-out of the concrete shaft eyes. Universal tapered precast concrete segments are typically installed as the machines progress, with shorter steel segment sets utilised during the course of the sharp radius curves. The geology along the project is typical for Bangkok, generally comprising stiff to very stiff clay, with lenses of sand and a groundwater head of about 2 bar.

Tunnelling on the project commenced in September 2018. “We started out straight into the 35m radius curve with the first machine, going under a busy five-lane road and around the corner of an exclusive department store at the intersection with Phloen Chit Road,” explained Khunviriya. “This is an old building, so the foundation piles extend down about 20m. The tunnel is at exactly the same level, so we had to be very careful not to cause any settlement. We also had to negotiate the Skytrain foundations on the other side, giving us a window with about 1m either side of the machine through the intersection.”

An array of monitoring equipment in place to check for any tunnelling induced settlement recorded zero movement during the curved drive. Ital-Thai credits much of this success to the skill of the Terratec field service team, whose experienced TBM operators steered the TBM throughout the curve and is assisting TBM operations and maintenance throughout the project.

Focus on the project has now switched to the second 4.27m diameter Terratec machine which launched in January and is currently excavating a 1,349m long tunnel from Lumphini Park to the Chidlom terminal station. It is due to complete this drive in September. Each machine will then execute a further short curved drive to complete tunnelling on the project.

Designed to accommodate a new high-voltage cable system, the Chidlom cable tunnel project is one of a series of tunnelling projects being undertaken by the Bangkok Metropolitan Electricity Authority, which are being built to answer increased power demands in the Thai capital. The projects will also improve the reliability of the power transmission system and reduce the risk of physical damage to conventional above-ground power lines as a result of accidents and storms.

Terratec has a well-established regional base in Thailand, having sold its first machine in the country eight years ago for the MRT Blue Line metro extension project. Since then, Terratec has become the leading TBM supplier to Thailand, with nine machines supplied to Thai projects in recent years.

References

- EPBMs chosen for Pune Metro drives – TunnelTalk, May 2019

- Metro Orange Line progresses in Bangkok – TunnelTalk, April 2019

- Breakthrough celebrations in Mumbai – TunnelTalk, March 2019

Tight radius machine en route to Bangkok 29 Nov 2018

A new 4.27m diameter Terratec tight radius TBM is due to be shipped to Thailand to enable a challenging alignment on the Bangkok Metropolitan Electricity Authority Klong Daan Cable Tunnel.

Designed to accommodate a new high-voltage cable system, the Klong Daan Cable Tunnel Project is one of a series of tunnelling projects being undertaken by the MEA, which are being built to meet increased power demands in the Thai capital. The Thai contractor is See Sang Karn Yotah.

“We have used a number of Terratec machines on past tunnel projects, including contracts for the Bangsue Wastewater collection system and Installation of the main underground conduit for electric and related works,” said Ekaphong Rungruang, See Sang Karn Yotah Project Manager. “Those machines were very well suited to the ground and that, along with Terratec’s experience in designing high-performance TBMs and the quality of its field service, was the reason we decided to select Terratec for the cable tunnel at the Klong Daan Substation.”

Located to the south east of the city, the Klong Daan Cable Tunnel Project is situated in the Bang Bo District of Samut Prakan, and is subject to tight alignment constraints imposed by the need to follow public road easements. To achieve this, the Terratec EPBM has been designed with an X-type articulation system, which can accommodate extremely tight horizontal curves. The machine, which is capable of excavating a minimum radius curve of 48m, will be used to conduct three tunnel drives (of 1,128m, 875m and 795m in length), at a maximum depth of 31m, each beginning or ending with a tight curve. It achieved factory acceptance this month.

Geological conditions along the tunnel alignments will consist of mixed faces of very stiff to hard or silty clay and very dense to very fine sand. The TBM’s soft ground cutterhead therefore features a spoke design with a 70% opening ratio and the addition of knife bits to assist break-in and break-out of the concrete shaft eyes.

Traditionally reinforced, 250mm thick by 1200m wide, Universal tapered precast concrete segments (4 + key) will be installed as the machine progresses and muck removal, segment transport and machine supply will be via rail bound equipment.

Machine operation will be assisted at all times by Terratec highly-experienced field service staff, providing quality after sales support to ensure optimum performance and successful project completion.

Following the successful factory acceptance test, the machine will be now shipped to Thailand and is expected to arrive in mid-2019.

References

- Challenging drive ahead for Bangkok Metro – TunnelTalk, August 2018

- Preparing for second challenging drive in Bangkok – TunnelTalk, November 2017

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.