Discussing Seattle TBM repair strategy30 July 2014

With the world’s largest TBM idle in the ground following the well-publicized failure of the bearing seals that protect its main bearing, a high-level delegation from the project’s contractor team of Dragados and Tutor Perini (Seattle Tunnel Partners), journeyed to Japan for urgent talks with senior representatives of the machine’s manufacturer, Hitachi Zosen.

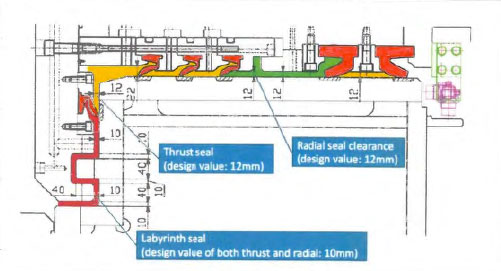

Among those present at the talks were STP Project Manager Chris Dixon, who spoke in detail to TunnelTalk about the nature of the repairs being carried out, the “aggressive” repair schedule, enhancements that are to be made to the machine, and the sealing of a deal that will see Hitachi Zosen bearing the cost of TBM repairs for the time being. STP, for its part, will assume responsibility for costs associated with excavation of the recovery shaft through which access will be gained to the 17.48m diameter machine’s cutterhead, main bearing, bearing block and ruptured sealing system.

Dixon also answers questions relating to STP’s estimate for the costs associated with the repair and as required under its contract with WSDOT. The extra costs associated with the repair of the machine and under the provisions of a potential change order clause in the design-build contract are estimated by STP at US$125 million. WSDOT has rejected the estimate and the basis of a potential change order claim, which is yet to be submitted officially and ruled upon.

Podcast – Chris Dixon speaks to Peter Kenyon of the TBM recovery and repair

References

- STP Repair Plan (June 16)

- Bertha bearing to get 86-tonne reinforcement – TunnelTalk, June 2014

- TBM Bertha repairs strategy – TunnelCast, April 2014

- Twelve month repair job for TBM Bertha – TunnelTalk, April 2014

- Addressing the Bertha bearing seal issues – TunnelTalk, February 2014

- WSDOT questions contractor TBM decisions – TunnelTalk, March 2014

- TBM Bertha suffers bearing seal failure – TunnelTalk, February 2014

- Hyperbaric inspections begin in Seattle – TunnelTalk, January 2014

- Investigating the Seattle mega-TBM stoppage – TunnelTalk, January 2014

- Dewatering to help deal with stuck Bertha – TunnelTalk, December 2013

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.