WSDOT questions contractor TBM decisions

12 Mar 2014

Peter Kenyon, TunnelTalk

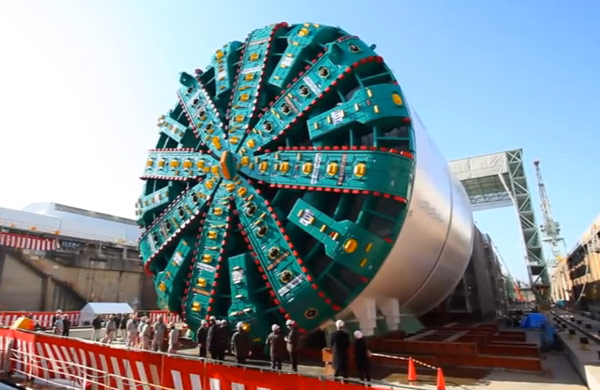

- Correspondence between WSDOT and STP has shed new insight into the tense relationship between owner and contractor as the Dragados/Tutor Perini team grappled with problems that forced the initial shutdown of TBM Bertha.

-

TBM Bertha has moved 2ft in three months

- In a letter to Matt Preedy of WSDOT, dated January 15, STP Alaskan Way Project Manager Chris Dixon responds to 11 questions put to STP by the project owner two days previously. The letter has been made public following a media application under state public disclosure legislation.

- The letter reveals a series of concerns that WSDOT's technical team had about the TBM, its commissioning and testing, and appears to question operational decisions made by the contractor in the run up to Bertha hitting what turned out to be an 8in diameter steel casing pipe, forcing shutdown of the machine on December 6 last year.

- WSDOT announced on January 2 that the location of the steel pipe was identified in the design-build contractor's reference materials, and that therefore any costs associated with damage to the TBM and resultant project delays would be the contractual responsibility of STP. Dixon, however, clearly disputes this in his response to Preedy's questions.

- Should striking the steel well casing be deemed responsible for what is now known to be damage to the main bearing seals, and what might potentially be damage to the main bearing itself, it seems likely that a legal battle over who should pay is inevitable.

- Asked what "resequencing" plans STP might have to mitigate delays caused by damage to the TBM (which at that time was not being attributed to damage to the seals that protect the TBM's main bearing, but rather to possible cutterhead damage relating to the steel pipe) and the need to carry out further investigations and possible repairs, Dixon replied tersely: "STP will generate a schedule recovery plan if and when one is deemed necessary.

-

Correspondence between STP and WSDOT

- "Currently, the scope of work for repairs and any potential delays are still unknown, at least until current phase of the plan, hyperbaric interventions to inspect cutterhead and excavation plenum, is completed. Once the extent of the damages, and therefore of the delays, are more clearly understood, the need for a recovery plan will be assessed."

- He goes on: "Since the steel pipe, per our previous correspondence, is WSDOT's responsibility and liability under the contract, WSDOT has always had the option to accelerate the work, at WSDOT's expense, to mitigate any delays." Earlier, Dixon claimed that STP was only told about the steel casing "six days after it was encountered by the TBM."

-

In the letter WSDOT also

• questions STP changes to the conditioning agent mixture as

the drive progressed

• demands an explanation of the contractor's possible future

plans to change the specified cutting tools

• queries "potential causes of the wear experienced in the

screw conveyor housing and other TBM parts" and questions

other "wear issues" that might require new parts

• accuses STP of "operating [the TBM] as a 'blind shield' in some

areas of the drive, using cutting head chamber pressure to

force tunnel muck up the ribbon screw conveyor, and then

utilizing partially closed cut off gates to control the rate of tunnel muck removal." This action, claims Preedy, "is

not consistent with the intended or designed normal operation for this TBM," adding, "Please further explain

how you intend to operate the TBM from this point forward and whether your operations plan needs to be

modified"

• asks why no hyperbaric interventions had taken place prior to its reaching ring 149, claiming that contract

provision called for "at least three" to have been carried out

• demands an explanation for running the machine at "extremely high temperatures prior to the shutdown on the

afternoon of December 6," before going to ask whether any failsafe mechanisms were overridden

• asks why the head of Dragados underground technical department Enrique Fernandez disappeared from site at

the moment when his input might be most helpful

- In his responses Dixon addresses all the issues raised, though he does concede that the TBM had suffered "severe wear" to the screw conveyors, a problem that was to be addressed once the machine reached Safe Haven 3. He denies the accusation that 'blind shield' operation was inconsistent with the machine's design, referring WSDOT to Tunnel Work Plan documents. Changing soil conditioning mixtures is attributed to experiencing changing ground conditions and a desire to optimize the system.

- WSDOT's suggestion that the machine was operated at "extremely high temperatures" prior to shutdown was simply untrue, said Dixon. He explained: "The TBM was not operated at extremely high temperatures. The temperatures would rapidly rise until the cut off temperature was reached which would shut the TBM down. A cooling period was allowed which brought the temperature back down to the previous operating average temperature. The high rate of temperature increase can be attributed to the high temperature and heat capacity of the soil in the cutterhead and the cutterhead itself.

- "The heat generation sources that continued to feed into the ground could have been the steel on steel friction from the steel pipe as well as the friction between the ground and the cutterhead with severely damaged cutting bits, due to impact with the steel pipe. Failsafe mechanisms were not overridden during the period leading up to the shutdown. In this particular case, the failsafe mechanism for the main bearing seals is set at 70°C for the machine. The first cut off temperature was set at 60°C, and then increased to 65°C to see if better results could be achieved. However, the final failsafe temperature was never changed or exceeded.

- The correspondence between STP and WSDOT follows on from the findings of an Expert Review Panel, reported by TunnelTalk last week, which highlighted a number of key areas where the owner and its contractor need to work better together to get the project back on track.

- Investigations into possible machine damage, and how best to repair the damaged seals that protect the TBM's main bearing, are ongoing. STP and experts from the machine's manufacturer, Hitachi Zosen, are expected to release a recovery plan in the coming weeks although it is anticipated that access to the cutterhead will be by way of a shaft excavated in front of the face, rather than from inside the machine itself.

-

Letter from Chris Dixon (STP) to Matt preedy (WSDOT), January 15, 2014

STP-WSDOT clashes threaten Seattle project - TunnelTalk, March 2014

Addressing Bertha's bearing seal issues - TunnelTalk, February 2014

TBM Bertha suffers main bearing seal failure - TunnelTalk, February 2014

Hyperbaric inspections begin in Seattle - TunnelTalk, January 2014

Investigating the Seattle meg-TBM stoppage - TunnelTalk, January 2014

Dewatering to help deal with stuck Bertha - TunnelTalk, December 2014

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.