International bid for Norway rail project

Dec 2008

Shani Wallis, Editor

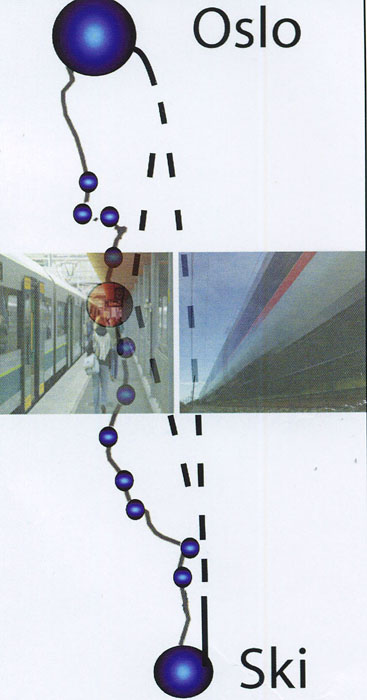

- An international invitation to bid is being considered for construction of Norway’s longest and largest rail tunnel project to date. To meet social, environmental and technical goals, some 18km of the new 24km long twin-track rail line between Oslo and the southeast commuter town of Ski is in mined tunnels. The route is completed with sections of cut-and-cover through shallow softer deposits on the approach to Oslo’s main station, with a new station at Ski and short lengths of at-grade track in between. Attracting international competition is expected to cap costs and provide keen value for public money in Norway’s normally closed construction market.

- Public funding of the estimated NKr11 billion ($US1.5 billion) project is not an issue for the oil-rich country, but commitment to its construction has become a key campaigning matter for next year’s national elections in September. Peak hour capacity on the existing twin-track line is at its limit and increased capacity to the south is needed to upgrade national passenger and freight rail transportation. There is immense pressure from local and opposition politicians for government to commit to construction of the project and have it in service as soon as possible. The new double-track Follo Line with design train speeds of up to 200km/h will shorten travel times, improved punctuality and more than double rail capacity through the corridor.

- Allocation of NKr50 million ($US7 million) in the current government’s annual budget announced in October confirms project development through 2009, but fails to give clear commitment to the project. The next ten-year National Transport Plan for the period 2010 to 2019, due out in February, is expected to also include support of the new line. However, the Norwegian National Rail Administration has warned that funding the project through the usual annual budget grants falls short of committing to its construction within a rational five to six year period and rather extends its realisation out to 12-15 years with a construction start no earlier than 2013. Political pressure wants construction to be brought forward and for the line to be in service as soon as possible. A shorter 5 to 6-year construction period would also realise savings of about NKr1.5-2 billion ($US200-285 million) over the projected 12-15 year period of the current funding programme.

-

Tunnel design considerations

Two alignment options and three different design concepts are being considered for the new rail line. Alignment Alternative A includes a stop at a new, two level intermediate station at the town of Kolbotn while Alternative B runs directly between Oslo and Ski without any stops. The three concepts considered in respect to operating safety and construction logistics of the long tunnel are based on two options: one for a single tube, double track tunnel with a cross section of 118m2, and one for twin, 70m2 single-track tunnels.

-

Existing line (left): new options (right)

- Both single-tube, double-track options are designed as drill+blast operations with five main construction/access tunnels and Option A providing an additional 13 smaller escape tunnels to the surface. In addition, option B includes a full-length, 25m2 parallel service tunnel with escape connections every 1,000m. The twin-tube, single-track concept is considered applicable for drill+blast or TBM excavation and incorporates escape cross passages at 500m intervals.

- Drill+blast is used widely in Norway and offers flexibility for tunnelling through variable rock conditions. Early investigations predict largely good quality hard gneiss and amphilolite bedrock with high uniaxial compressive strengths, but with fractured rock and fault zones expected along the alignment. Large joint spacings are also a common feature in gneiss formations. Rock TBM tunnelling also has a long history in Norway and offers different advantages over the drill+blast options.

- The alignment passes through heavily populated areas, which attract social and environmental restrictions on blasting, construction traffic, noise, and dust. Maintenance of groundwater levels is also a specific concern to protect the quality of potable and storage water aquifers and avoid surface subsidence. Protected the operating tunnel from freezing winter conditions is also a major life-cycle maintenance concern. The TBM concept is based on using four TBMs working two each in opposite directions from one main access tunnel. The drill+blast concepts require five access tunnels to limit drill+blast headings to no more than 2,000m each and these five access tunnels total 1,480m for alignment A and 2,810m for the alignment B route. The one access tunnel for the TBM tunnel option is located at about mid-point, in a remote, rural location, and is 240m or 1,020m long, depending on the alignment selected.

-

Different design concepts

- Selection of the project’s final alignment is due to be announced by early 2009 with the choice of the preferred design option and method of construction unlikely before end 2009/early 2010 once further design studies have been concluded.

-

Water control

“Water control and environmental concerns speak in favour of the TBM alternative,” said Arnulf Hansen of AMH Consult, adviser to the National Rail Administration for the feasibility, planning and preliminary design stages. TBMs of 10.25m o.d. will be needed to comply with minimum 9.1m i.d. regulations for single-track rail tunnels in Norway and excavation is designed as a double-shielded TBM operation with a bolted and gasketed precast concrete segmental lining erected behind. “This mitigates the water ingress risk and provides quantifiable life-cycle maintenance cost advantages,” said Hansen. A final in situ concrete lining is not required for the drill+blast options but new regulations by the National Rail Administration specifies a water and frost protection shell throughout new rail tunnels. - “Initial reports indicate that both drill+blast and TBM methods are likely to be competitive for the twin single track tunnel concept,” said Hansen. Geological investigation and exploration will be based on surface mapping, core drilling, and the experience gained during current drill+blast construction of a nearby highway tunnel and from other tunnels and caverns built in the area along the Oslo-Ski rail tunnel alignment.

-

Core samples

-

Way forward

“As of now, the project’s future is unknown and is yet to be decided by the politicians,” said Anne Kathrine Kalager, Project Manager for Jernbaneverket, Norway’s National Rail Administration, “but we are strongly recommending that a full funding agreement be confirmed for the project to get it approved, designed and constructed within a reasonable five to six year period. Opening the construction contract to international tender will further maximise taxpayer value for money.”

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.