Historic TBM breakthrough in Norway

10 Dec 2015

TunnelTalk reporting

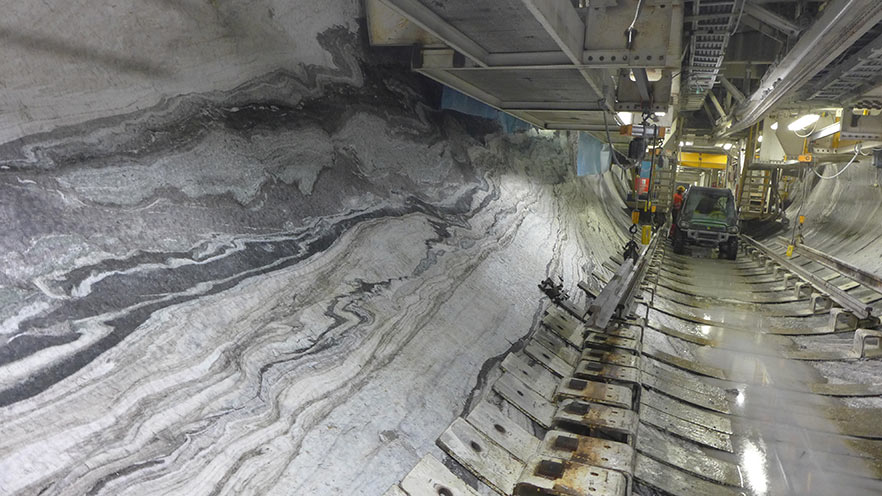

- Breakthrough today (December 10) at Røssåga in the frozen Arctic Circle marks completion of the first TBM hard rock drive in Norway in more than two decades.

- Contractor Leonhard Nilsen & Sønner AS (LNS) selected the refurbished Robbins main beam gripper TBM for its ability to cost effectively excavate 12km of headrace and tailrace tunnels needed to increase the output of the existing Lower (Nedre) Røssåga and Upper (Øvre) Røssåga hydropower stations.

-

Røssåga team ahead of TBM launch

- The hard rock TBM launched in January 2014, following Onsite First Time Assembly (OFTA), for the first of two drives. Today’s breakthrough is on the longer 7.4km parallel headrace tunnel that serves the Lower Røssåga powerhouse.

- The 7.23m diameter Robbins machine came well-equipped for potentially difficult hard rock conditions. A Measurement While Drilling (MWD) system was capable of analyzing the ground ahead of the TBM, while continuous probe drilling and McNally ground support system capabilities were also included.

- Crews are reported to have encountered a number of challenges, including water inflows and sections of very hard, solid rock of up to 300 MPa UCS. Some adjustments were needed to the cutter rings, but the TBM was able to achieve an average production rate of 160–170m/week, including a best of 250m/week. A best daily advance rate of 54m was recorded.

- Now that tunneling on the Lower Røssåga headrace is complete, project owner Statkraft plans to commission the tunnel in Spring 2016. Check a future edition of TunnelTalk for a full project report.