Major contract announced for Oslo water supply 18 Jun 2020

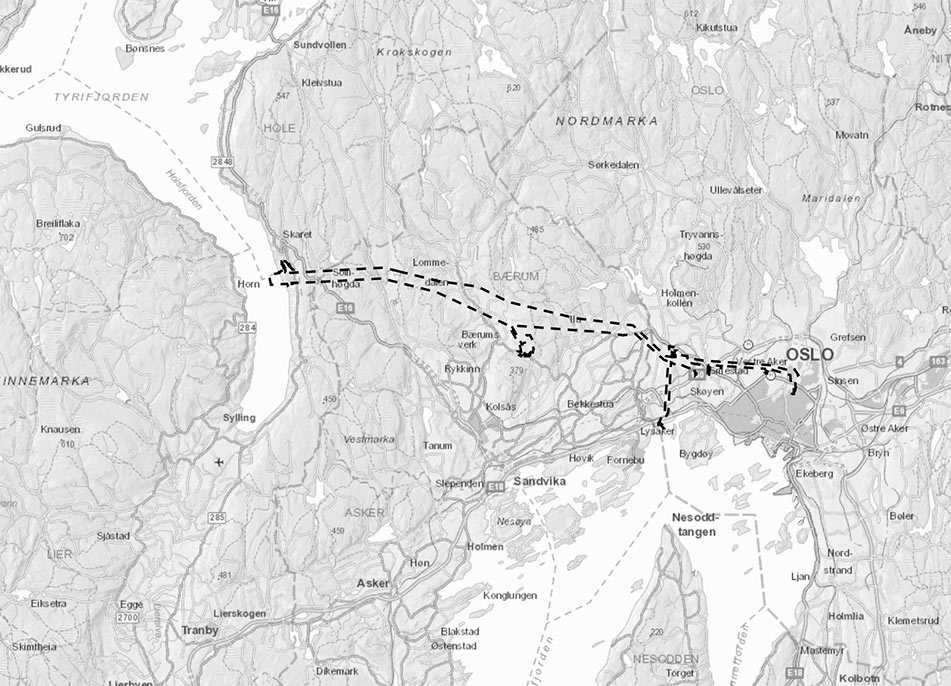

A single contract has been presented to the market for construction of the new 19km long raw water supply tunnel for Oslo, the capital city of Norway. Design specifications by the client, the City of Oslo Municipality, call for two hard rock shielded TBMs and a precast concrete segmental lining to excavate and line the raw water conveyance from Holsfjord and Huseby to the west of the city (Fig 1). Estimated with an 85%-probability, the NOK12.5 billion (about US$1.36 billion) project is the largest single investment by the Oslo Municipality.

In length the tunnel is as long as the recently excavated twin tube Follo line railway tunnel near Oslo, with successful final breakthroughs in February 2019 of four 10m diameter hard rock shielded TBMs, erecting a precast segmental lining and progressing from a central launch adit and job site. The two 5.2m diameter TBMs, for the minimum 3.6m i.d. raw water supply tunnel from the Holsfjorden lake, as the source, to the water treatment plant at Huseby, will progress from each end towards an inline junction.

“Interest from the market has been great,” said Anna Maria Aursund, Director of water and wastewater treatment for the Water and Sewerage Agency, “and we expect a good round of bids from many competent contractors. According to our project programme, start-up of excavation by the machines is scheduled for late Summer 2022 at Holsfjorden and at Huseby by the beginning of 2023.”

The tunnel alignment is deep below the ground, under the municipalities of Hole, Lier, Bærum and west parts of Oslo. As well as TBM excavation, a further 100,000m3 of drill+blast excavation will create the water intake and access adits to the TBM assembly and operating chambers.

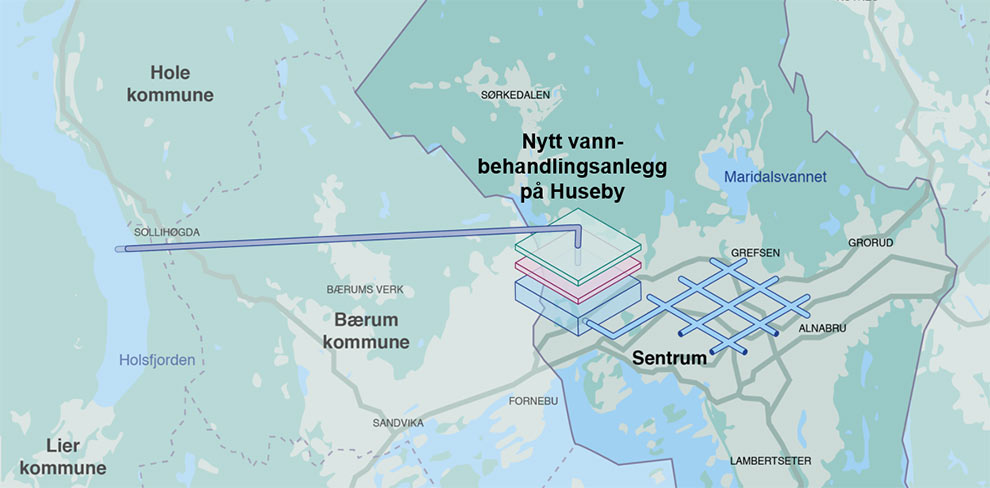

There are eight major contracts in the NOK12.5 billion project, of which the main tunnel is one of the three largest. The first contract was awarded earlier this year to Skanska for the rock work and access tunnel at the Huseby site. Physical work on site is expected to start in the third quarter of 2020. The project also includes construction of a state-of-the-art water treatment plant being built under the Husebyskogen forest at Huseby and a clean water tunnel to be built from Huseby to Sagene to bring drinking water into the existing supply pipeline network of Oslo.

Today, 90% of the residents of Oslo receive water from the single Oset water treatment plant at Maridalsvannet. The new capital works project establishes a reserve water supply to ensure access to drinking water in a situation where the water supply from the main water source is interupted or depleted. Project New Water Supply Oslo will ensure an adequate reserve water supply for the city by 2028.

References

- Oslo selects TBMs and segments for new water project – TunnelTalk, October 2019

- Tailor-made TBMs for Norwegian hard rock – TunnelTalk, February 2019

- All TBM boring complete for Follo Line – TunnelTalk, February 2019

Oslo selects TBMs and segments for new water project 17 Oct 2019

Two double shield TBMs with a precast segmental lining are selected by the Municipality of Oslo to excavate a 19km long raw-water supply line for the city of Oslo. The TBMs, one working from the fresh water intake in the Holsfjorden lake to the east and the other from the treatment plant site at Huseby in Oslo, will progress towards an in-tunnel breakthrough and provide the permanent precast segmental lining to a minimum i.d. of 3.6m.

“Both drill+blast and TBM excavation was considered for the project,” explained Project Director Steinar Johannessen, “and all comparables came down in favour of the TBM option with a precast segmental lining. Excavation of the tunnel is on the critical path of the project and the TBM option provided a robust and lower cost expectation for meeting the programme, and avoided an intermediate adit and working jobsite in one of the three municipalities under which the alignment passes. The circular profile of the TBM drives with the precast lining also reduces the head-loss on the gravity flow of the water conveyance and optimises the excavation cross section, with the TBM option being about 60% of the face area required for a drill+blast option.”

The new water supply project is required to provide a 100% redundancy for the current potable water supply infrastructure for the city of Oslo, 90% of which comes from a single source. Water will flow by gravity from the intake to a pumping facility for lifting into the treatment plant (Fig 1). From the treatment plant water will flow through another part of the tunnel and into the city distribution network (Fig 2).

With the new infrastructure programmed to be completed and in operation by 1 January 2028, approval of the environmental and social impact statements, and of the estimated 85%-probability investment of NKr12.5 billion (about US$1.36 billion), is anticipated from the Oslo Municipality in November to permit invitation of tenders for the contracts soon after and a start of construction in 2020. The conveyance tunnel will be let as a single contract on a bill of quantities and according to the standard Norwegian NA 8405 form of contract.

Application of a TBM excavation and segmental lining is a repeat of the successful use of double shield TBMs and the precast segmental lining for the recent Follo Line twin tube railway project in Oslo. The two TBMs of about 4.5m-5m in diameter for the water project will work through complex rock geology at up to 350m below surface, and will encounter the potential for high volume, high pressure water ingress and rock instability. As on the Follo Line, extensive horizontal pre-excavation grouting and systematic probing will be part of the excavation process.

“Systematic pre-excavation grouting is expected for about 70% of the alignment,” said Johannessen, “particularly from the inlet for the east heading where anticipated water ingress must expect water head pressures of up to 35 bar. For this reason we have specified large capacity, high performance drilling and grout pumping equipment on the TBMs.”

For the segmental lining, two types have been designed, one with gaskets for a watertight lining for about 3km of the tunnel under dense urban areas at the treatment plant end of the project, to protect the natural groundwater regime and prevent any ingress contamination of the raw water conveyance, and a non-gasketed, draining lining for the remainder of the alignment to the intake. “Designing a gasket to withstand 35 bar ingress water pressure, we believe, has not been achieved so far,” said Johannessen, “and in any case, a watertight lining for the reaches under open country is not required. The systematic pre-excavation grouting through areas of high ingress will control potential ground water inflow to within environmental protection and operational regulations.”

Following the success of the Follo Line project, and the successful reintroduction of TBM excavation to Norway on other recent projects, there has been keen interest in the project from Norwegian and European TBM construction contractors. “The project team for the Municipality of Oslo invited TBM contractors for talks earlier this year,” said Project Manager Fredrikke Syversen, “and with no prequalification process, the interested contractors await release of tender documents by end of the first quarter of 2020 latest.” Both Syversen and Johannessen worked previously on the Follo Line project for the railway authority owner Bane Nor and bring their experience to the new water project.

Tunnelling works on the project are due to start by summer 2020 and are programmed to take approximately four years to complete.

References

- Tailor-made TBMs for Norwegian hard rock – TunnelTalk, February 2019

- All TBM boring complete for Follo Line – TunnelTalk, February 2019

- Pre-excavation grouting – a Nordic focus – TunnelTalk, June 2017

- Mechanised breakthrough inspires in Norway – TunnelTalk, January 2018

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.