Soil grouting alternative to ordinary cement 10 Oct 2019

With the development of urban construction, there are many foundation excavations required in soft soils. The supporting structure of a foundation excavation should have the dual function of retaining soil and controlling groundwater. The common forms of a surrounding structure in soft soils include a composite soil nailing wall, a support wall of soil mixing piles, and a slab support system using the soil mixing wall system.

These types of surrounding structures generally require a wall of soil mixing piles or rotary jet grouting piles to stop water and retain soil. When soil mixing piles or rotary jet grouting piles constructed using ordinary Portland cement are constructed according to quality and maintenance standard, they can generally meet the requirements. However, the following problems exist in the construction of cement-soil mixing piles:

- For saturated silty clay with a high water content, the strength of the mixing pile or rotary jet grouting pile is often lower than that of the design requirements.

- For silty soil and sandy soil, the impermeability of the wall of soil mixing piles or rotary jet grouting piles is poor.

- The structure is less durable in corrosive environments, especially in chloride sulfate contaminated environments.

- The poor hydration of ordinary cement results in an inconsistent formation of hydration products. This weak distribution, non-compact soil micro-structure, combined with insufficient strength leads to doubling of the quantity of soil mixing injection required.

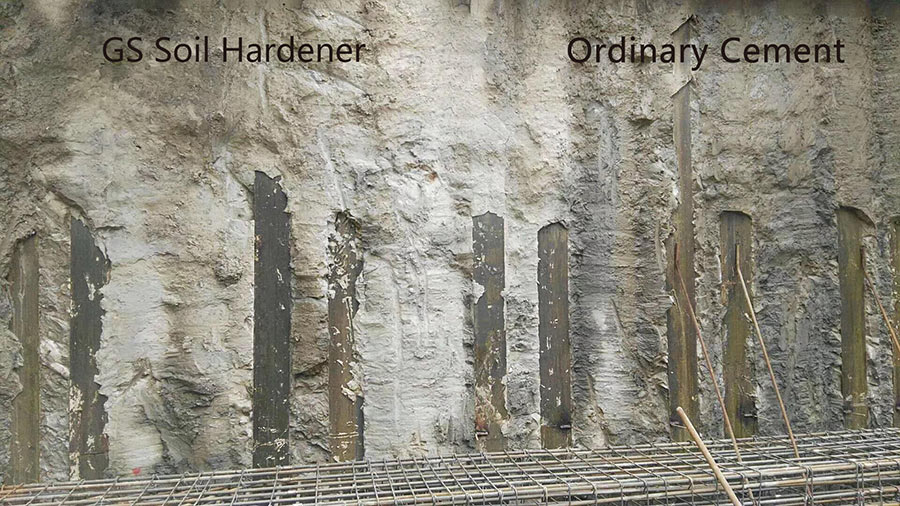

Practice has proven that the use of GS Soil Hardener can significantly improve the strength of soft foundation soils. It is a high-performance cementitious material suitable for soil mixing piles, rotary jet grouting piles and high-pressure grout injection operations that can replace ordinary cement completely. Application of GS Soil Hardener effectively improves the safety of foundation excavation engineering, the bearing capacity and durability of roadbed engineering, and improves the impermeability of waterproofing grout curtains.

Introduced in 2016, the new powder product has exhibited the following performance advantages.

- Easy constructability: The fineness of GS Soil Hardener powder and the fluidity of the slurry mortar it creates when mixed are similar to those of cement. Soil mixing piles with sufficient strength and permeability can be formed by mixing the GS mortar with soil.

- Anti-seepage effectiveness: The permeability coefficient of soil reinforced with GS Soil Hardener is less, by about a magnitude of one, to soil reinforced with P.O42.5 cement grout. This will be sufficient for engineering projects with higher anti-seepage requirements.

- Highly economical: The cost of GS Soil Hardener is no higher than that of P.O42.5 cement, yet the strength of reinforcement is higher than that of cement-soil mixing when the content of GS Soil Hardener is the same as that of cement.

- Higher strength at both early and final curing stage: The unconfined compressive strength of GS Soil Hardener reinforcement can exceed 50-100% that of cement-soil consolidation at the same curing stage. As a result, less maintenance is required for curing and there are time savings in the construction process.

- Social and environmental benefits: In GS Soil Hardener, the total amount of recycling of industrial waste or creation of by-products, such as smelting and power, is more than 70%. By making full use of slag as an industrial waste resource, the environment can be protected.

- Versatile applicability: It can be applied in a wide range of saturated soils including marine sedimentary soil, coastal silt, silty clay, sandy silt, mucky soil, and other soil types, and can be widely used in foundation treatment, foundation excavation support, building cushion, for water seepage resistance, and for water control in mines and underground excavations.

Product technology

Based on the characteristics of soil and the requirement of engineering performance, GS Soil Hardener adopts the industrial waste slag plus composite admixture as the basic technical feature to improve the shortcomings of soil consolidated with cement. The shortcomings include poor hydration, insufficient Ca2+, difficulty in continuous distribution of hydration products and insufficient durability to develop new soil hardness. When using GS Soil Hardener, the time and space distribution of hydration products occur orderly, which is conducive to the formation of the most compact of consolidated soil structures.

Research results show that when using cement to reinforce saturated muddy clay with high water content, the hydration products of cement are mainly calcium silicate hydrate and not many calcium vanadium stones. Therefore, it is difficult to effectively reduce the free water content in muddy clay, resulting in low strength of cement reinforced soil. Compound additives in GS Soil Hardener have double effects of sulfate and alkali activation, which can stimulate the activity of waste slag fully. Cementitious materials generate calcium vanadium stones with high crystalline water in soil by converting free water into crystalline water and filling the pores in soil. At the same time, hydrated calcium silicate with cementation is constantly produced. The strength of reinforced soil is therefore greatly improved.

GS soil hardening agent is based on soil characteristics and engineering performance requirements, combined with floor materials, industrial waste and composite admixture as the basic technical route.

Main use and applications

GS Soil Hardener can be widely used for soil mixing piles, rotary jet grouting piles for foundation excavation supporting structures, soft soil foundation reinforcement, cushion materials for building floor construction, soil stabilisation for roadbeds and for foundation reinforcement. From 2016 to 2018, A total of 28 GS Soil Hardener demonstrations or pile test projects were completed. These include applications on the Wenzhou sewage treatment plant project, the foundation excavation for the Baolong City Square shopping mall project in Shanghai and the Shanghai Dayuecheng deep foundation. With sales exceeding 100,000 ton,the application scope covers gravity fill dams, soil mixing wall construction, and jet grouting pile reinforcement among many others.

Customers include general contractors and professional construction enterprises including the Wuhan Surveying-Geotechnical Foundation Co, the Shanghai Construction Group, the China Construction Eighth Engineering Division Corp, the China Construction Industrial & Energy Engineering Group, the China Baowu Group, Strong Foundation, Jiangxi Geological Construction Co and Shanghai Geological Construction Co.

The GS Soil Hardener product is produced by the start-up company Baofang Material Technology which is devoted to the research, development, production and marketing of new materials.

For more details email Shan Weiliang or telephone +86 1391 634 9583.

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.