Next generation synthetic fibre range from EPC 27 Oct 2015

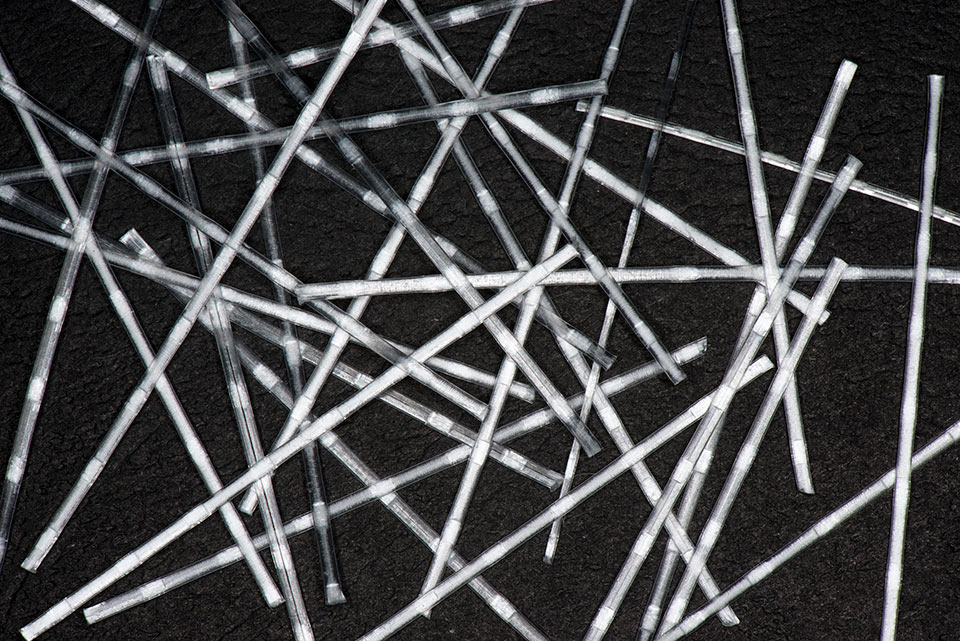

Elasto Plastic Concrete (EPC) introduces its latest generation of high-strength synthetic fibre reinforcement products: EPC DucTil.

The company’s own testing enables it to lay claim to the highest tensile strength and Young’s Modulus of any macro synthetic fibre ever produced to date. EPC DucTil also features the newly developed Flexuous Embossing, designed by EPC to improve bond behaviour.

“Over the past four years we have critiqued every aspect of fibre design and combined this with 15 years of real world experience to create a new standard for macro synthetic fibre reinforcement, our EPC DucTil fibre range,” said Matthew Clements, EPC’s Chief Executive Officer.

EPC Ductil fibre has a tensile strength of 700 MPa, the highest ever seen in macro synthetic fibre reinforcement, and a Young’s Modulus 50% higher than EPC’s existing BarChip fibre range and nearly three times that of other synthetic fibres on the market. It also features the all-new Flexuous Embossing, designed to improve bond with the cement matrix.

These features combine to give EPC DucTil exceptional performance, with the company’s own testing results demonstrating an overall ductility improvement of as much as 20%. This performance increase has been gained through an improvement in material quality and design quality and not through increased dosage or fibre length, and at no expense to workability.

Since the first EPC fibre was launched in Australia in 2000, EPC’s Future Fibre R&D Program has increased fibre performance by more than 300% while simultaneously decreasing dose rates and hence costs by nearly 70%. EPC DucTil continues this trend.

“The exciting new EPC DucTil range has opened whole new fields of possibilities for our synthetic fibres,” said EPC Chief Engineer Ralf Winterberg. “Our design engineers now have the right tools at hand to address vital issues in civil engineering, such as crack width control, fatigue resistance and seismic behavior.”

With the new EPC DucTil fibre range, Elasto Plastic Concrete continues to prove it is one of the world’s leading sources of knowledge for macro synthetic fibre reinforcement.

EPC’s BarChip synthetic fibre has seen the company grow from a small operation in Australia into a global enterprise with an extensive network of offices and distribution partners. The company has been a leading player in the field of synthetic fibre technology in both the mining and civil tunnelling sectors.

In Australia alone, more than 1,000km of primary ground support systems employing concrete and shotcrete have been reinforced with BarChip structural synthetic fibres, and BarChip fibres are currently being sprayed or cast into concrete for at least 20 different tunnel projects around world.

Previous civil underground projects include the Caltrans Devil’s Slide twin bore road tunnel in California, the St Helena Tunnel in New South Wales, Australia, and the North Strathfield Rail Underpass in Sydney, the Caldecott Fourth Bore, USA, and the Hindhead road tunnel in the UK, among many others.

References

- Steel fibre expert Ralf Winterberg joins EPC – TunnelTalk Career Moves, Sept 2014

- Pushing progress at Devil’s Slide – TunnelCast, February 2010

- Devil’s Slide opening ceremony – TunnelCast, March 2013

- Caldecott Fourth Bore topheading complete – TunnelCast, November 2011

- Hindhead road tunnel opens in UK – TunnelTalk, July 2011

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.