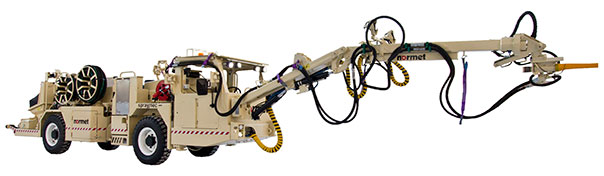

Normet introduces new equipment units 25 Nov 2014

Normet launches its new generation of underground construction and mining equipment in the MF- and LF-series at the Bauma China 2014 exhibition in Shanghai, China. The new offering sets a new standard for comfortable underground driving with unique axle suspension system and redesigned ergonomic cabins.

The new offering is ready for Industrial Internet, with machines able to register all data and transfer it for further analysis via WLAN. The new range will be rolled out during 2015, with several engine options to fulfil different exhaust emissions regulations around the world.

Normet sets a new standard for comfortable driving in underground mines and construction sites in both the 10 tonne and 16 tonne classes by introducing a hydraulic axle suspension system which is specially designed for underground hard-driving conditions. The suspension improves comfort levels for both operators and passengers travelling across the uneven ground that characterises underground construction sites, minimising fatigue and vibration levels. The suspension enhances vehicle handling at higher speed, reduces cycle time, and increases the productivity and efficiency of the vehicle. It also reduces vehicle wear and maintenance costs. Front axle suspension is available for all Utimec, Multimec, Variomec, Charmec, Spraymec and Himec product families in MF- and LF-series. Utimec MF- and LF- personnel (PER) transporters feature both front and rear axle suspension to provide the same comfort level for driver and the passengers in the transport compartment. The suspension system can also be easily retrofitted to older models.

The new FOPS and ROPS approved safety cab provides superior visibility and a comfortable compartment for the driver and passenger. Wide door openings, handrails and ideally positioned non-slip steps allow for easy entry and exit. Enclosed cabs have a noise level of <80 dB.

The new offering comes with a new electrical system and the second generation NorSmart control system. Traditional gauges have been replaced with the new Multi Information Display (MID) which provides all the necessary driving information including speed, fuel consumption, RPM and temperatures. NorSmart can record all vehicle data including speed, gear selected, use of brakes, engine and hydraulic oil temperatures, engine and gearbox oil pressures. All sprayed concrete and charging work process data is recorded on the Spraymec and Charmec range of products. The recorded data can be transferred for further analysis and supervisory checks via WLAN or by USB. Site specific Industrial Internet applications such as M2M and remote diagnostics can be arranged through NorSmart.

For Bauma China 2014 the Multimec MF100 cassette carrier with 10 tonne payload capacity is displayed as an example of the new offering. The Multimec system consists of a series of cassettes, each manufactured for a different purpose - material, concrete, fuel, lube, personnel transport, as well as service and scissor lift cassettes that all fit on the common carrier. The rugged load handling device means the carrier can switch cassettes in less than one minute.

References

- Normet reveals new range of spray robots – TunnelTalk, April 2014

- Normet adds D-Bolt to its range of services – TunnelTalk, February 2013

- Normet unveils its new charging concept – TunnelTalk, October 2012

- Normet completes full acquisition of TAM – TunnelTalk, June 2012

- Normet global expansion recognised – TunnelTalk, February 2012

- Normet acquires Esswerk Berg – TunnelTalk, August 2011

- Normet expands its Mexico operations – TunnelTalk, November 2011

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.