Monitoring machine braking for safety 24 May 2018

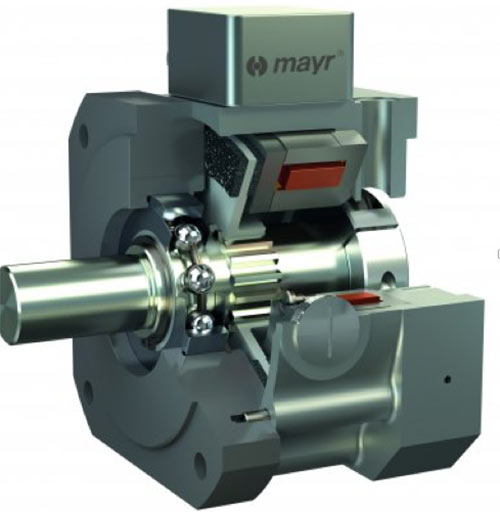

To monitor safety and allow smooth deceleration of machines, Mayr has developed a co-ordinated friction braking system which also increases machine productivity and offers predictions for maintenance requirements. The system connects to the internet for constant monitoring.

The new ROBA brake checker and ROBA torqcontrol monitor facilitate the smooth deceleration of machines and devices. The brake checker operates without sensors as it analyses current and voltage and recognizes the movement of the armature disk to determine the condition of the brake. It can deduce temperature, wear and tensile force reserve, ie whether the magnet still has sufficient force to attract the armature disk.

When the tensile force reserve is reached the ROBA brake checker emits a warning signal, but with reserve time to spare before the brake needs replacing. The ROBA brake checker is also available in an AC voltage version, and a further version of the device will in future have the capacity to supply the new brake too.

Where braking needs to be gentle and controlled, Mayr supplies the ROBA torqcontrol module to apply torque control. It can change the level of braking torque by controlling current and voltage so that devices and machines can be evenly and gently decelerated.

ROBA-SBCplus offers both brake checking and safe control in one package. Developed in collaboration with Pilz, and used especially for situations where passengers are carried and safety and comfort are key, the ROBA-SBCplus module operates with wear-free electronic semi-conductors, and so achieves practically unlimited switching frequency and switching reliability.

The ROBA-SBCplus brake control unit is type-certified by TÜV Süd (Technical Inspectorate, Southern Germany) and can be used up to the highest Performance Level PLe and Safety Integrity Level (SIL) 3.

References

- New couplings for drive constellations – TunnelTalk, August 2017

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.