-

Continuing the cast-in gasket discussions

Steve Casey, Sales & Technical Director of VIP Polymers, has responded to the feedback contribution from Peter Tiedemann of gasket supplier Dätwyler to this News Release by VIP and to the general discussion about the design and performance of cast-in sealing gaskets for tunnel lining segments as reported in the TunnelTECH article of May 2016.

Read what Casey has to say on our Feedback page and share your comments and experiences of researching, adopting or working with the techinique via our Feedback facility.

New technology to avoid segment cracking 02 Feb 2017

Cast-in gaskets for tunnel segment linings are gaining popularity in the industry with the increase in demand generated by owners, designers and contractors. The proviso for adopting the alternative to post application of the gaskets is that the cast-in method avoids causing cracks in the segments during ring-build installation as cracks in segmental linings are costly to repair and lead to project delays.

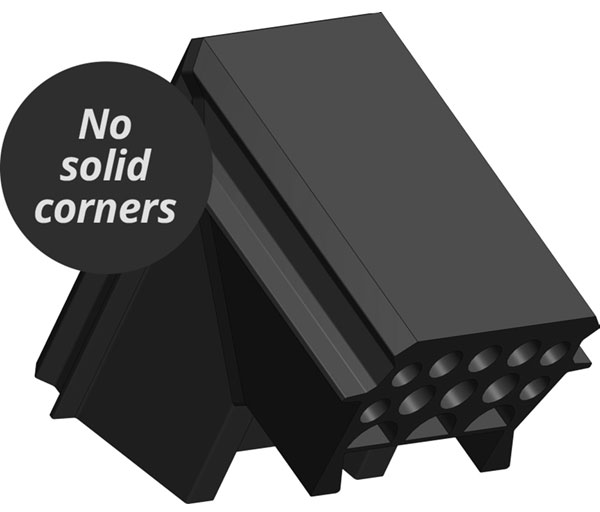

Paramount to the process of avoiding cracks and damage to segments with cast-in gaskets during construction is design and fabrication of the corners of the gaskets.

New technology developed by VIP Polymers of the UK reduces the risk of segment cracking with the ability to produce gasket corners to any angle.

Designing the gasket corners to obtuse, acute or 90 degree angles to match each segment corner, allows the gasket to compress evenly across the full gasket face and accommodate segment movement to reduce point loading at the corners.

VIP’s cast-in tunnel segment gaskets allow engineers to optimise their segment designs safe in the knowledge that there are high performance gaskets able to accommodate any segment corner angle.

In addition to the angle cutting machinery and jointing presses, VIP has commissioned a new gasket extrusion line and new in-line cutting technologies.

VIP Polymers is to promote its new cast-in gasket manufacturing processes at the Arabian Tunnelling Conference in Dubai during 20-21 February 2017. A review of currently available cast-in gasket systems and products was published in TunnelTalk in May 2016.

References

- Modern seals for segment lining integrity – TunnelTalk, May 2016

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.