TBM excavation begins for Kuala Lumpur Line 2 15 Mar 2018

Building on the legacy of the Line 1 experience, the first of eight refurbished VDM (variable density TBMs) previously used on Line 1 was launched in early March to begin excavation of 13.5km of twin tube running tunnel for the Kuala Lumpur Klang Valley metro system in Malaysia. Excavation of the Bandar Malaysia North underground station box provides the working access and launch site for the first of 12 TBMs to link the 11 stations on the 13.5km underground section of the city’s second 52.2km long mass transit route.

Prime Minister Najib Razak of Malaysia (inset right) joined Transport Minister Datuk Seri Liow Tiong Lai (insert left) to launch the first of 12 TBMs to work on the KVMRT Line 2 underground route

Marking the official milestone, Prime Minister of Malaysia Datuk Seri Najib Razak pressed the button to launch the refurbished Herrenknecht VDM (variable density) TBM on its 1.4km drive towards the Chan Sow Lin underground station where it will be re-launched to complete the 1.275km drive to the Line 1 interchange Tun Razak Exchange underground station. Four TBMs arriving from both directions at Tun Razak Exchange station will be dismantled underground and removed either through Chan Sow Lin or Conlay Stations. The refurbished machine will be joined by other seven refurbished Line 1 TBMs – five refurbished DVMs and two refurbished EPBMs - and an additional four new Herrenknecht VDMs to complete the total 27km of segmentally lined underground route between the north and south transition portals in 16 separate drives (Fig 1). All twelve Herrenknecht TBMs are planned to be in operation by the end of 2018 with four of the machines relaunching in early 2019 for the final two, twin tube reaches (Table 1).

Continuing its association with the metro system, the same MMC-Gamuda construction JV that completed the underground section of the central underground section of Line, was awarded the MR15.47 billion ringgit (about US$4 billion) underground central section of Line 2 by MRT Corp, the Mass Rapid Transit Corporation, of the Malaysian Government, in March 2016. Retaining the eight Herrenkencht TBMs used on Line 1, gave the JV a competitive advantage over its rivals for the Line 2 contract. Refurbishment of the eight machines is said to have saved the MMC-Gamuda up to RM400 million or about 15% of what it would have cost to purchase new machines.

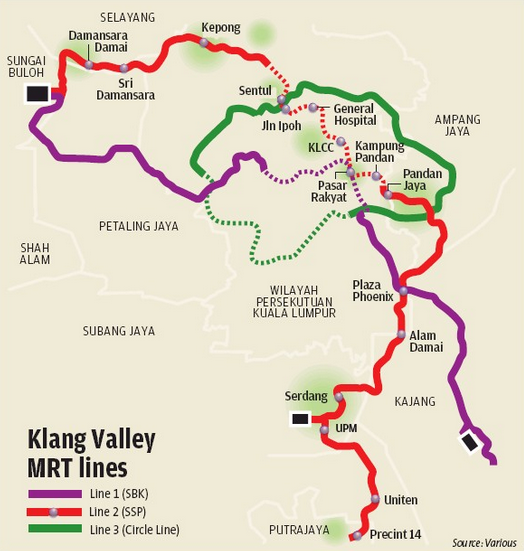

Fig 1. Line 2 in red, is 52.2km long with the central 13.5km and 11 of the 35 stations aligned underground

Refurbishment for reuse

In addition to being well maintained during their drives and with detailed records kept throughout their operation to monitor maintenance and provide useful information for the refurbishment process, preservation measures were applied to the Line 1 TBMs, before they were placed in long term storage ahead of refurbishment for use on Line 2. MMC-Gamuda then worked with Herrenkencht to complete a comprehensive rebuild of the machines for their Line 2 reuse.

In explaining the refurbishment completed, Gus Klados, Director, Tunnels for the JV for Line 2 and for the previous Line 1 project, emphasized the risk taken by MMC Gamuda “and the trust we had in our judgement, that these VDM machines - that existed only on the drawing board when we ordered six of them from Herrenknecht in 2012 - would work as hoped for in reality”. Operation of the machines in the karstic limestone geological conditions and the EPB clay deposits under the city of Kuala Lumpur certainly proved their worth with all of them completing their drives with no major technical difficulties or issues and with the concept now being applied on tunneling projects elsewhere in the world.

The refurbishment process included stripping, cleaning, refurbishment and replacement of worn parts, modification and upgrade of other components and progressed to factory acceptance tests. Each cutterhead was assessed separately and fully repaired as necessary. Two of the cutterheads that had suffered particular wear around the periphery were rebuilt with harder wearing Vautid blocks.

Main bearing assessment

The main drive sealing, rotary couplings, thrust and articulation cylinders were pressure tested to confirm their integrity and the erector bearings were inspected and found reusable except for on one machine which was replaced. The screw conveyors were checked for wear and rebuilt and protected with hard facing as necessary and all safety, hydraulic, electric, lubrication, grouting, and soil conditioning systems were checked and repaired as required.

The design life (L10) of the main bearing in each of the machines was calculated by Herrenknecht and bearing supplier SKF and the residual life of all was found to be more than sufficient to cater for their Line 2 applications. The remaining L10 life of all the bearings was found to be in excess of 300% of their projected operating hours for the Line 2 drives.

The bearing in one of the TBMs was replaced after it completed more than 4km on Line 1, launching from Cochrane station, boring through the Tun Razak Exchange and Bukit Bintang underground stations and continuing after being pulled through Merdeka Station to a final break through into Pasar Seni Station. The VDM was the first launched on Line 1 in June 2013 and the last to breakthrough in April 2015 and after working in the VDM mode through limestone at the start and in EPBM mode through the complex Kenny Hill Formation of multiple metamorphic deposits of clay, silt, sand, phillite and a section of 290MPa quartz on the alignment. On inspection, its main bearing showed signed of some soil contamination damage and was replaced with a new one.

| Table 1. Proposed schedule for launching two TBMs, one month apart, at each Tunnelling Unit (TU) working access site with four TBMs relaunching in 2019 after completing their initial Line 2 drives and dependent on station excavation progress to provide launch and working accesses |

“The life of the bearings was a subject of scrutiny by the client,” explained Klados, “and the analytic table of each was submitted with our tender for the contract.”

Rotary crusher sizer

The one item of modification was the operation of the rotary crusher and sizer component on the slurry circuit of the VDM machines (Fig 2). These crushers/sizer units sit above the slurrifier box and had proven to be a bottleneck in poor blocky ground conditions during Line 1 operations. Paul Trevisin, Senior Project Manager for MMC-Gamuda, explained that as part of its modification, “the configuration of the crusher drums and tools was redesigned to change the angle of inclination of the drums to lie more horizontally above the slurrifier box and reduce the tendency for stones to fall rapidly to the end of drums. The crusher tools were also changed to roadheader picks for a more aggressive jaw action.”

The modified crushers will allow the VDMs to pass through those challenging local karst conditions without being slowed by the blockages. “The four new VDMs ordered from Herrenknecht for Line 2 were equipped with the modified crushers,” explained Klados.

Other upgrades, described by TBM Manager Ng Kok Peng, involved modification of the flushing systems into the EPBM and VDM excavation chambers. “The two EPBMs had their rotary couplings changed to provide an extra passage to flush the central double cutter region of the cutterhead to prevent blockages and the central flushing ports into the excavation chamber of the VDMs were redirected to deliver further forward and prevent blockages around the double cutters during high-density excavation operation.”

The rotary crusher sizer above the slurrifier box in the DVM slurry system underwent improvement modification

“For two of the new VDMs machines we have had them fitted with dual manlocks to facilitate faster cutterhead interventions for tool changes,” said Klados. “This is expected to be necessary for working through the highly abrasive granite on the northern drives between Titiwangsa Sation and the north transition portal.”

With the first of the 12 TBMs now underway and its twin drive machine preparing for launch within the coming weeks, the concentrated effort to complete the underground section of the new Line 2 for the underground system is underway and towards a line opening deadline in 2022.

Circle Line procurement

As TBM tunnelling gets underway on the underground central section of the new KVMRT Line 2, news is reported that two consortia are shortlisted for construction of the third MRT3 Circle Line. Designed now as an all-underground route, the two consortia are the MMC-Gamuda JV and joined for MRT3 by George Kent company, and a consortium lead by the China Communications Construction Company (CCCC) which presented strong competition for the Line 2 underground construction contract.

The Malaysian Government approved construction of the MRT3 Circle Line in October 2017 and conducted initial industry briefings with four turnkey project contractors in November. The other two consortia are reported as the Sapura Group-TIEC-Samsung Corp consortium and the Pacific Construction-Mudajaya-JEC group. As part of their proposals, the MMC-Gamuda-GK and CCCC consortia will also be required to offer a financing package to contribute to funding the estimated RM 45 billion (US$11.5 billion) MRT3 project. The Circle Line is last of the three-line metro development proposed to the Government by MMC-Gamuda in 2010. Following this, the JV was engaged as the Project Delivery Partner to realize Line 1 of the masterplan.

References

- KVMRT to repeat Line 1 success for Line 2 – TunnelTalk, April 2016

- Final breakthrough ends KVMRT TBM tunnelling – TunnelTalk, April 2015

- Kuala Lumpur Line 1 starts full operation – TunnelTalk, July 2017

- High honour for metro director in Malaysia – TunnelTalk, September 2017

- Honours for an international tunneller – TunnelTalk, February 2017

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.