Hiroshima heavyweight for hard rock in Japan 11 Oct 2018

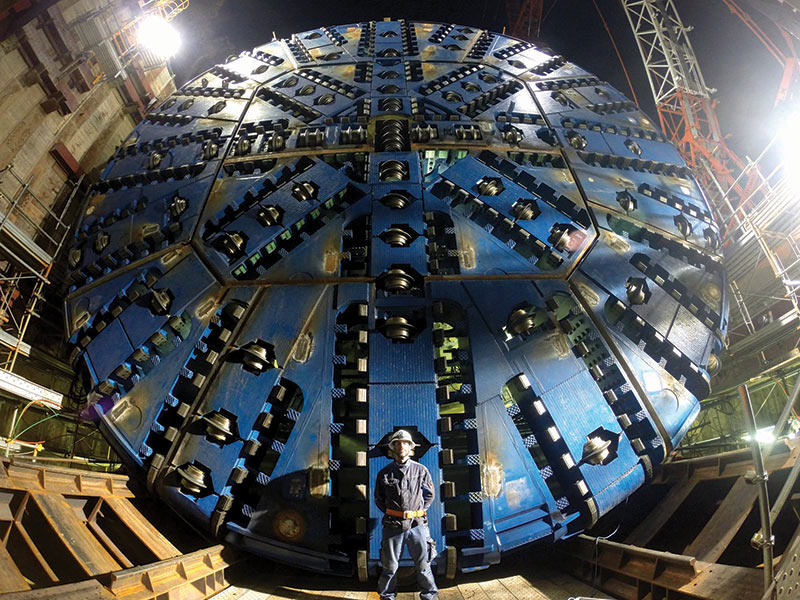

A Robbins mega-sized slurry machine, measuring 13.7m (44.8ft) in diameter, has made its first cut into hard rock

in Japan.

The massive machine is the country’s first foreign-made large diameter Slurry TBM to excavate hard rock in Japan. “There is a lot of hard rock in Hiroshima,” said Ryota Akai, Deputy Project Manager for the Obayashi-Tasei-Kosei JV, “and Robbins has a lot of experience boring hard rock.” The machine is expected to encounter granite with rock strengths up to 130 MPa (19,000 psi) UCS.

The epic launch on September 18, 2018, at an urban jobsite was made possible by Onsite First Time Assembly (OFTA) of the TBM in Japan for the Hiroshima Expressway Line 5 project. The contractor had a strict timeline of eight months to adhere to when it came to machine assembly. “This deadline was very important. After assembling the TBM, I think OFTA was appropriate for this project,” said Ryota Akai, Deputy Project Manager for the Obayashi JV.

Due to the project location there were also restrictions on delivering the TBM. In order to meet controlled transportation limits within the city, the TBM had to be divided into small transportable weights and sizes, then assembled in a small jobsite measuring just 30m (100ft) wide x 60m (200ft) long. The 2,400 metric tonne (2,650 US tonne) machine will bore 1.4km (0.9 miles) of the 1.8km (1.1 mile) long tunnel that, once completed, will significantly improve traffic conditions in Hiroshima.

Those involved in the project are excited to see what effect the use of this machine will have on how slurry TBMs are used in the future. “The development of this TBM is a milestone,” said Kiyomi Sasaki, General Manager of Robbins Japan, “it will lead to new tunnel applications worldwide.”

The design of the slurry machine is robust in anticipation of potentially abrasive rock conditions and water pressures up to 13 bars. “The Robbins machine is very tough, and the weight very heavy. The cutterhead material and structure are both very tough. It will not break in hard rock,” said Akai.

In preparation for the conditions, the machine was designed for 20-bar water pressure. The robust cutterhead was fitted with 20-inch and 17-inch diameter pressure compensating cutters, which utilise a patented design to effectively operate under high pressure. The joint venture intends to change the disc cutters an estimated 10 times during the bore as part of the machine’s maintenance.

Throughout the assembly and launch process the joint venture crew worked with Robbins supervisors who assisted and provided guidance. “Robbins crews have a lot of experience; they help us every day despite the language barriers. I appreciate it,” said Akai.

The new Expressway Line 5 tunnel will directly connect Hiroshima’s urban area with a major national highway network and is expected to improve access to Hiroshima Airport. Tunnel completion is planned for 2020.

References

- Twin Crossover TBMs prepare for Mumbai Metro drives – TunnelTalk, July 2018

- Rebuilt main beam for water diversion in Chicago – TunnelTalk, March 2018

- Mixed ground TBM ready for Mumbai Metro – TunnelTalk, September 2017

- Robbins TBM equipped for high pressure water control – TunnelTalk, August 2017

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.