Progress on Mumbai Metro Line 3 06 Sep 2018

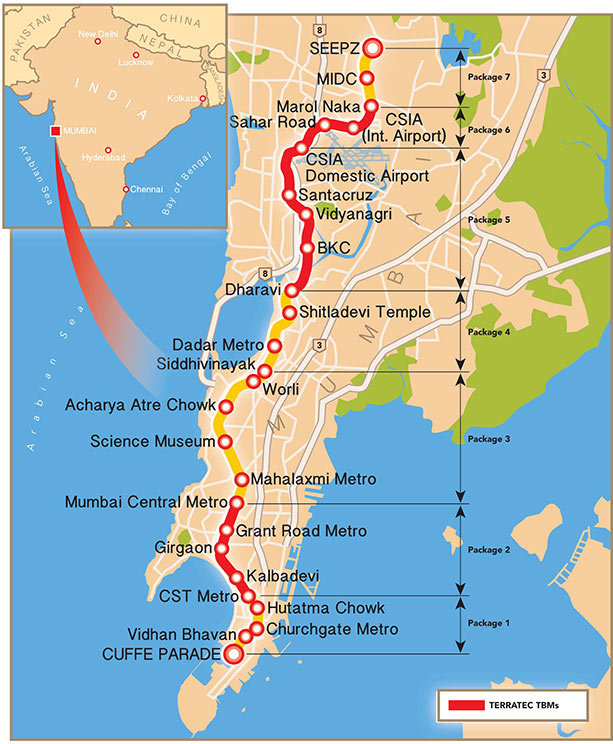

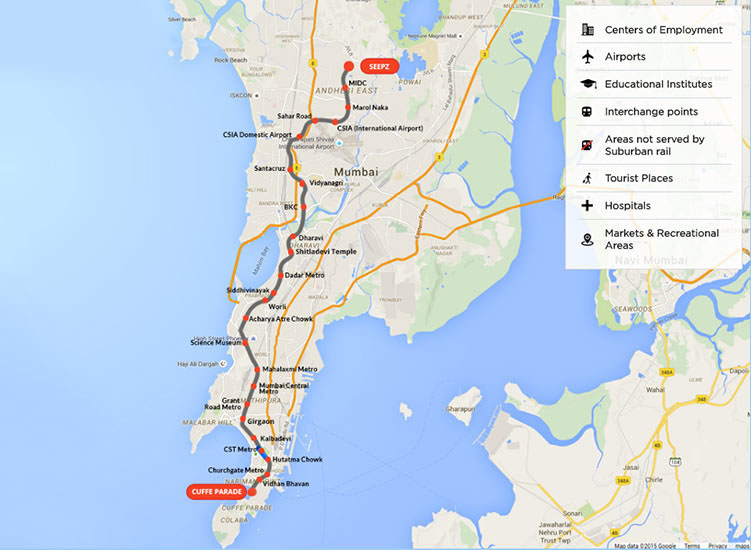

Work is progressing well in Mumbai, India, with 17 TBMs either in operation or preparing to launch for excavation of the 33km long, twin tube all underground metro Line 3. In August 2018, Terratec assembled the fifth of its seven TBMs to work on the project. The 6.68m diameter dual mode hard rock TBM will join the other four Terratec machines already working on the project. The first four have achieved advance rates of up to 15m/day and 91m/week during the early stages of their drives on contracts 2 and 5. The new machine will work on Contract UGC-06 and progress from the CSIA International Airport shaft.

The two 6.68m diameter dual-mode hard rock TBMs are being used by the HCC Hindustan Construction Company / Moscow Metrostroy JV awarded Contract 2 of Line 3 by the MMRCL Mumbai Metro Rail Corporation in July 2016. Both machines are excavating the 14km long twin tunnels from the Chhatrapati Shivaji Terminal (CST) TBM launch shaft and are currently excavating towards the Mumbai Central Station receiving shaft (Fig.1).

The other three new Terratec dual-mode hard rock TBMs are being used by the J. Kumar – China Railway No. 3 Engineering Group JV for the excavation of sections on the line’s 4.94km contract 5 (Dharavi Station – CSIA Domestic Airport TBM receiving shaft) and the 4.45km contract 6 (CSIA Domestic Airport – Marol Naka TBM receiving shaft), which were also awarded last July.

In addition to the hard rock TBMs, Terratec has supplied two re-manufactured 6.61m diameter mixed rock EPBMs, which will also be deployed by the J. Kumar – China Railway No. 3 Engineering Group JV in Mumbai. These TBMs were recently used on Delhi Metro new Pink Line and have since undergone extensive refurbishment in order to fulfil a section of highly weathered ground on contract 5.

“We have again selected Terratec as a project partner after using four Terratec TBMs on our Delhi Metro contracts (CC20 & CC24), where we completed our tunnelling operations on time and without any issues. We believe our goals of safe and timely tunnelling will once again be achieved using Terratec technlogy,” said Urin Wanbanterng, UGC-06 Construction Manager.

Terratec is the lead TBM supplier on the Mumbai project with a 41% market share.

References

- Buzz words to concentrate efforts in 2018 – TunnelTalk, January 2018

- TBM orders for Mumbai Metro Line 3 – TunnelTalk, February 2017

First deliveries to Mumbai with more to follow 31 Aug 2017

The first two of seven Terratec TBMs to be engaged on excavation of the new fully underground Metro Line 3 for the city of Mumbai is on its way to India following successful factory acceptance tests earlier this month.

The first of these is the first of two new 6.68m diameter dual-mode hard rock TBMs that will be deployed by the HCC (Hindustan Construction Company) / Moscow Metrostroy JV to build the 4.049km twin tunnels on the UGC-02 contract from Chhatrapati Shivaji Terminal Station to Mumbai Central Station (Fig 1).

The two machines launch later this year from a working shaft at the Chhatrapati Shivaji Terminal and progress towards Kalbadevi Station and onward to a reception shaft at the Mumbai Central Station for a total of four tunnel drives over the course of the project.

A second machine delivered this month was the first of three new 6.68m diameter Terratec dual-mode hard rock TBMs ordered by the J. Kumar – China Railway No. 3 Engineering Group JV for excavation of the 4.94km twin tunnels of the UGC-05 contract from Dharavi Station to the CSIA T1 TBM reception shaft and for the 4.45km twin tube of the UGC-06 contract from the CSIA T1 Station to the Marol Naka reception shaft.

The versatile single shield Terratec TBMs are equipped to operate in either open or closed mode in the predominantly fresh and slightly to moderately weathered basalt and breccia that are anticipated on the tunnels of these contracts, which were awarded by the Mumbai Metro Rail Corporation Ltd (MMRCL) to the two joint ventures in July last year (2016). The robust hard rock cutterheads are mounted with heavy duty 17in disc cutters, which are interchangeable with ripper tools and feature large bucket openings that provide a 10% opening ratio.

The machines also feature 2,000kW electric variable frequency drives that allow the cutterheads to cut efficiently in harder rock zones at maximum rotation speeds of 7rev/min and deliver a torque of 8,000kNm to cope with more fractured zones of ground along the alignment, as well as active shield articulation and built-in two component annular backfill grouting systems.

In addition to the new TBMs, last month Terratec also completed the successful factory acceptance testing of two re-manufactured 6.61m diameter mixed/rock EPB machines that will also be deployed by the J. Kumar – China Railway No. 3 Engineering Group JV on the Mumbai Metro Line 3 project. These TBMs were recently used on the new Pink Line of the Delhi Metro and have undergone extensive refurbishment to fulfil a section of highly weathered ground on contract UGC-05 in Mumbai.

When complete, the much anticipated Line 3 of the Mumbai Metro will be the first underground metro line in the city. The 33.5km-long line with 26 underground stations and one at-grade station, will connect Cuffe Parade business district in the far south to the Santacruz Electronics Export Processing Zone (SEEPZ) in the north-central (Fig 1).

Construction of the line is divided into seven tunnel-and-station packages awarded to five different contracting joint ventures in 2016. These five contractors will deploy a total of seventeen TBMs with Terratec being the lead TBM supplier on the project with a 37% market share.

References

- TBM orders for Mumbai Metro Line 3 – TunnelTalk, February 2017

- India, a reluctant powerhouse – TunnelTalk, December 2016

- Delhi Metro Phase III completes TBM excavation – TunnelTalk, February 2017

- Main beam TBM makes great time on water tunnel in Mumbai – TunnelTalk, February 2014

- Delhi Metro Phase III completes TBM excavation – TunnelTalk, October 2012

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.