Hawaii TBM faces steep curve radius challenge 15 July 2015

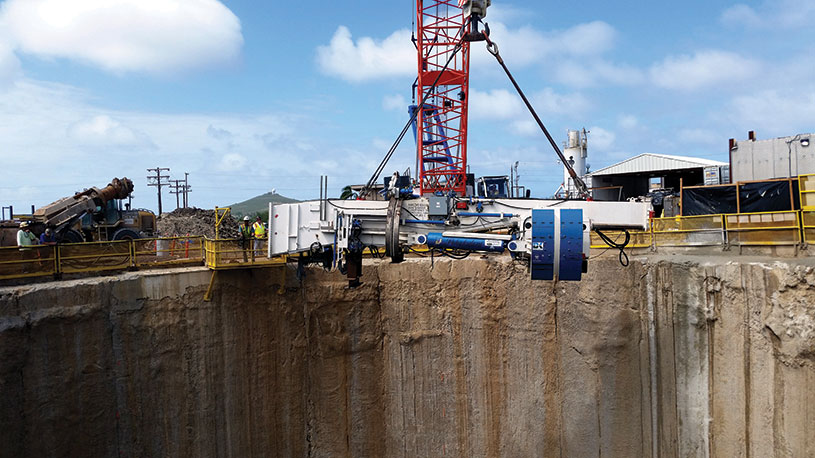

A Robbins 4m Main Beam TBM is making steady progress following launch in the spring for excavation of Hawaii’s longest tunnel.

The rock TBM started its 4.6km drive for a new sewer tunnel in Kaneohe, Honolulu, from a 23m deep starter tunnel. Contractor Southland/Mole JV is building the Kaneohe-Kailua Wastewater Conveyance Tunnel for the City and Council of Honolulu, with the aim of eliminating overflows during rain events. The tunnel contract is priced at US$173 million.

During the tunnel design phase, it was decided that the tunnel route should travel inland and deeper underground in order to bypass one of the few residential areas along the alignment.

Designers introduced an isolated 150m curve radius into the tunnel alignment that required the TBM to be designed with a unique back-up system. There will also be unusual operational procedures that come into play when crews come to navigate the tunnel curve. These will require the machine to be operated using half strokes rather than a full TBM stroke.

The curve is not the only unusual aspect of the tunnel. A tunnel of this scale has not been built in the Hawaiian islands before, and everything from the logistics of the tunnel operation to pre-grouting sections ahead of the TBM for groundwater control are new to Aloha State.

“There has not been a TBM of this size in the Hawaiian islands or a tunnel of this length,” said Tim Winn, Director of Southland. “The tunnel is being driven from an active Water Treatment Plant (WTP), and space is at a premium. There are also simultaneous contracts being performed at various locations that are outside the scope of our work.”

Winn added: “Robbins Field Service has been extremely valuable during assembly and commissioning of the TBM.”

As of June 2015, the TBM had excavated more than 300m and is currently advancing at a rate of 12–15m/day through a geology comprising basalt rock. Tunnel support is by rock bolts, steel arches, wire mesh and ring beams as necessary.

The TBM is scheduled to break through into the reception shaft at the Kaneohe Wastewater Pre-Treatment Facility in 8–10 months time.

The deep tunnel option was not the first design considered for the project: preliminary plans called for a smaller tunnel traveling under Kaneohe Bay. However, the deep tunnel option prevailed as a result of fears about excavation under the environmentally sensitive bay area.

“A number of factors were considered in making the decision to build a deep tunnel along the current alignment path, including reliability, construction costs, life cycle costs, environmental impacts, constructability and qualified contractor availability,” said Richard Harada of project consultant Wilson Okamoto Corporation.

References

- NTP and bid result for Hawaiian sewer tunnel – TunnelTalk, January 2014

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.