Gotthard TBM safely across the Piora Mulda

Nov 2008

- It was considered the greatest geological risk to the feasibility and success of the St Gotthard baseline rail tunnel project through the Swiss Alps. Extreme squeezing ground, uncontrollable running sands, and water ingress under tremendous hydrostatic pressure were all predicted for passage through the feared Piora Mulda. It is therefore with relief that the project confirms safe passage of the first Herrenknecht gripper TBM through a geological feature that comprises fine non-cohesive sugar-like sands.

-

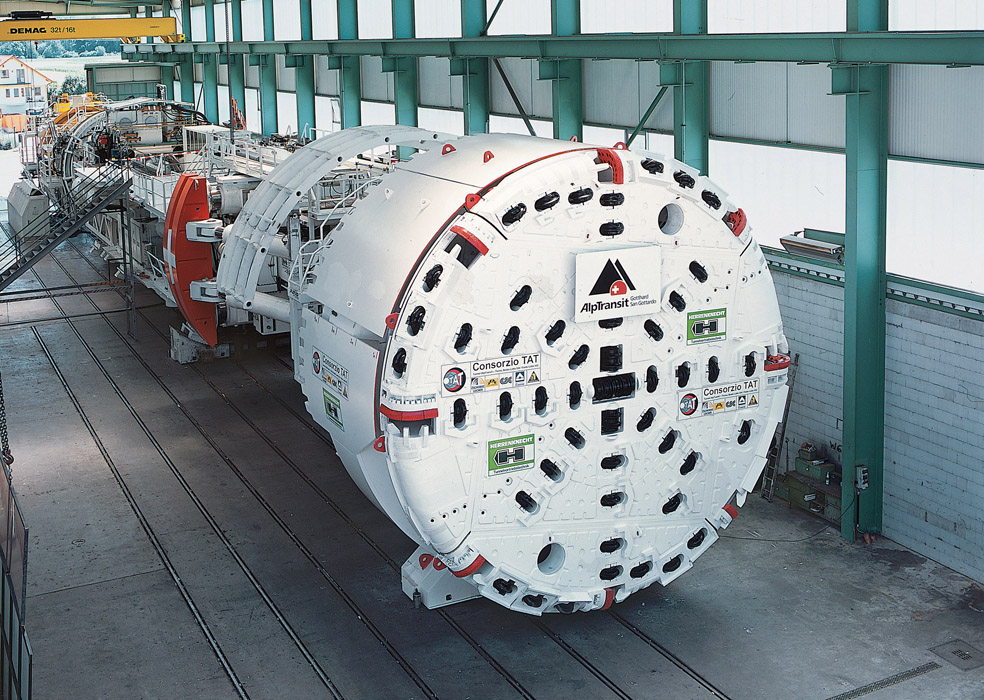

TBM S-210 ready for delivery in 2002

- Predictions of major problems through the estimated 150m long feature at the main tunnel alignment initiated one of the most extensive geological site investigations undertaken. The programme was completed during the 1990s and included a 5.5km long geological exploratory tunnel and from it, 19 deep gyro-controlled directional drilling bores to the main tunnel alignment some 350m below.

- Before entering the zone, the Herrenknecht gipper TBM S-210 in the east tube of the twin-tube tunnel was subjected to major overhaul and modification to ensure a successful crossing. The mechanical and electrical overhaul by contracting consortium TAT reduced the risk of TBM downtime on the planned non-stop TBM passage through the zone. "Even the regular maintenance shifts were skipped in order to prevent the risk of the TBM becoming jammed by rock deformations or ground squeezing," reported Heinz Ehrbar, Senior Tunnel and Rail Line Manager for the project's client organization, AlpTransit Gotthard AG.

- The TBM entered the Piora Mulda, under an overburden of 2,000m and in the very heart of the mountains on September 29, 2008. Its successful passage through was announced on Sunday, October 12, 2008. Rather than needing to rely on mitigation measures, tunnelling is reported to have progressed smoothly.

- Steel ribs of TH profiles were installed directly behind the cutter head on 1m centres and the rock surface was sealed with an immediate shotcrete layer. This was supplemented with subsequent layers of shotcrete to a total thickness of 300mm.

-

Steel arch and shotcrete support

- This support regime proved itself in practice. "We could not measure any deformations," explained Ehrbar.

- With success of the first TBM through the zone, its Herrenknecht twin in the parallel west tube (S-211) was about 1,400m behind (to end November 2008) and expected to arrive and start its run through the reach at the beginning of 2009. North of the geological feature, the machines, and their determined operating crews, have a further 7km of hard rock excavation under 2,000m+ overburden and with rock temperatures of up to 50°C to complete before they junction with the south headings of the drill+blast contract advanced from the 800m deep Sedrun access shaft by the Transco consortium.

- The two Faido TBMs (S-210 and S-211) are two of the total four machines working on the Gotthard Baseline project, all supplied by Herrenknecht. In the north, gripper machines S-421 and S-422 are being used by contractor Strabag and are some 3.2km and 1.9km respectively of the 7.4km long Erstfeld to Amsteg section. Strabag is contractor also of the 11.4km long Amsteg to Sedrun section and excavation of those twin tunnels was completed by the same two TBMs before moving on the Erstfeld section.

- According to AlpTransit Gotthard AG, tunnelling is moving forward as planned. By November 1, 2008, some 120.5 km, or 78.6%, of the total 153.3 km of tunnels, galleries and passages for the project had been excavated. During the month of October a total 2.1km of main tunnel excavation was advanced.

-

Fig 1. Gotthard Base Tunnel construction lots

- Previous Piora nightmares

Caution was a prudent move by managers and engineers working on the baseline tunnels from Faido ahead of meeting the Piora Mulda. During TBM excavation of the exploratory adit above, a probe drill on March 30, 1996 intersected the Piora Mulda for the first time. Within three hours, a water inrush under 150 bar pressure spewed some 1,400m3 of sugar-grained Dolomite through the 100mm diameter probe hole. The Wirth TBM used for the exploratory tunnel was recovered and the face was sealed off with an 8m thick concrete plug.- Subsequent laboratory analyses of cores retrieved by the exploratory tunnel's 19 inclined probe drillings revealed carbonate-sulfate trias or a rock with relatively good mechanical properties at the main tunnel alignment below. This was a significant omen for the project and one of the principal geological confirmations that allowed the project to go ahead. Fortunately, probe drillings ahead of the main running tunnel face in September also confirmed those earlier investigation results; the Piora Mulda dolomite at main tunnel level is hard, is non-aquiferous, and is suitable for mechanized tunnelling.

- There is still concern however for advance of the parallel heading, given earlier experience on the Amsteg section to the north. In June 2005 the trailing TBM of the two machines on that section for Strabag ran into a major fault zone and was stuck for a total five months. The complexity of the geology was illustrated in that the lead TBM passed through the same zone and not 40m parallel without a hint of the bad conditions that lay ahead of the approaching trailing TBM. Availability of the excavated parallel tunnel was a major advantage in the rescue operation of the stranded TBM.

- Despite various delays, and providing all progresses from here as planned, the official website of this most technologically demanding and politically complex engineering efforts of modern times, reports that all is on track to complete tunnel excavation by the first half of 2011 and for commercial train traffic through the mountain-base railway to start by the end of 2017.

- Elsewhere on the project, drill+blast of the north headings of the 6.8km Sedrun section from the deep access shaft by Transco ARGE is complete, while the twin drill+blast south headings are both struggling through what is referred to as an

- Previous Piora nightmares

-

Fig 2. Progress of Gotthard Base Tunnel

- 'interference zone'. Transco is a consortium of Implenia (CH), Frutiger (CH), Bilfinger Berger (D), and Pizzarotti, Bellinzona und Parma (I).

- From the south portal, final insitu concrete lining of the completed TBM excavated headings of the 16.6km Bodio section by the TAT consortium has recently finished. The final lining was installed using a 600m long self-propelling train of gantries, one in each tube, that re-profiled the tunnel cross section as necessary at the front; installed the waterproofing membranes, set the forms and cast the insitu concrete vault in the centre; and reinstalled the construction services' cables to the finished tunnel walls off the back.

- The long gantry trains, dubbed 'Wurms', were supplied to TAT by Bernold-Ceresola AG of Switzerland and Maschinen-und Stahlbau Dresden (MSD) of Germany, both part of the Herrenknecht Group. Both were designed to progress the final lining operation concurrent with advance of the TBMs and continuous operation of the muck-haulage and supply trains in the long 16.6km headings. The TAT consortium comprises Zschokke Locher (CH), Hochtief (D), Alpine Mayreder (A), CSC Impresa Construzioni (I), and Impregilo (I).

-

Ceneri breakthrough of Robbins TBM

- As a continuation of the Bodio section by TAT, the two Herrenknecht TBMs were overhauled at the contract's underground drill+blast multifunction station, and continued on into the Faido section. By November 1, the east TBM was well beyond the Piora Mulda zone, and the west TBM was advancing towards the geological syncline.

- Final lining and ancilliary construction work is progressing in the TBM excavated tunnels of the 11.4km Amsteg section by AGN Strabag while the same two TBMs were overhauled and were recently relaunched into the 7.4km Erstfeld section also for AGN Strabag.

- Ceneri Tunnel extension

Meanwhile on the project's associated 15.4km long Ceneri Tunnel, a milestone was celebrated on November 6th, 2008, when the 9.7m diameter Robbins TBM excavating the 2.4 km long Sigirino access adit broke through. The heading junctioned with installation caverns excavated by drill+blast at the alignment of the main baseline running tunnels.- The TBM was previously employed as one of four Robbins TBMs on the main headrace tunnel for the Kárahnjúkar hydropower project in Iceland and is the first TBM employed on the AlpTransit Project to be fitted with 19in disc cutters. The four machines on the Gotthard tunnel sections are fitted with 17in cutters. "Cutter performance has been the single most impressive result of this project," said Ferruccio Borroni, General Manager for Robbins Europa. Only about 30 cutter rings were changed in the last kilometer of boring, with the cutters excavating a combined 167,000m3 of hard rock. The geology consisted of competent schist, Swiss molasse, and Ceneri orthogneiss ranging from 30 to 130MPa (4,300 to 18,800psi) in UCS.

- The main beam TBM was procured for the Ceneri project by the Consorzio Monte Ceneri (CMC), a consortium of CSC, Lugano, Frutiger, Thun, Rothpletz, Lienhard + Cie, and Aarau. It was refurbished at a workshop near Milan and the cutterhead was also increased from its original 7.6m diameter to 9.7m. The 2.4km long adit was completed in approximately eight months having started in February 2008

-

Fig 3. Ceneri Base Tunnel and its progress

-

Funding

Currently, the most up to date estimates of the project's cost for AlpTransit Gotthard AG stand at CHF11.87 billion or about $US10 billion. This comprises CHF9.67 billion for the Gottard Baseline Tunnel and CHF2.2 billion for Ceneri. According to the project's official website, cost increases are credited to increased technical and financing charges and the long, 25-year implementation period, over which new developments in tunnelling standards and technology must be adopted and incorporated.

-

Robbins TBM from Kárahnjúkar to Ceneri

Express and high speed rail projects in Austria, North America and California - TunnelTalk -

Gotthard Baseline Tunnels Project

Herrenknecht

AlpTransit Lötschberg

Brenner baseline approach works in Austria Brenner Eisenbahn GmbH

Brenner Base Tunnel

High-speed rail link Lyon - Turin

California high-speed rail