TBM u-turn at Filder for Stuttgart-Ulm rail link 06 Sep 2018

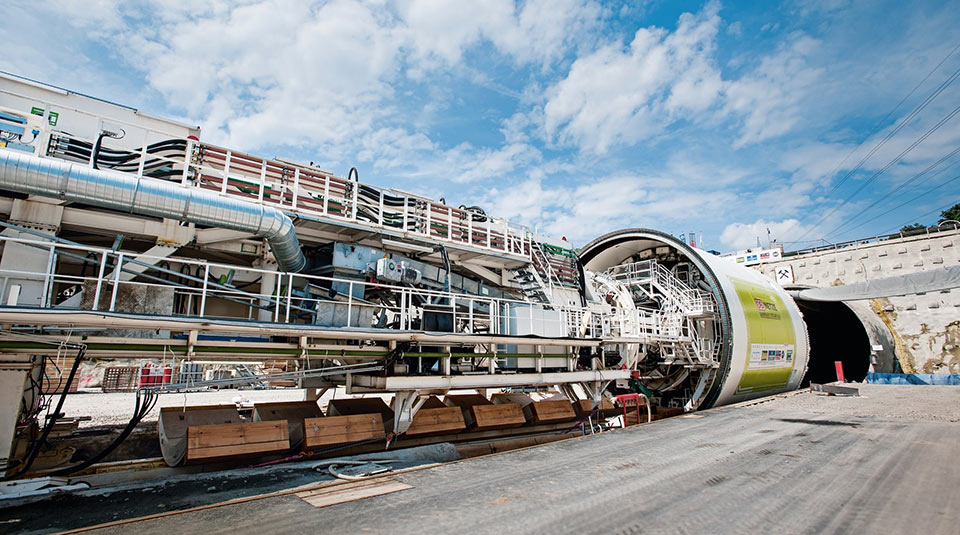

After successfully completing its third drive for the western tube of the 9.5km long twin tube Filder Tunnel on the Stuttgart-Ulm railway line in Germany, the 10.8m diameter Herrenknecht multi mode TBM is being disassembled underground and turned around to start the 3.4km final drive of the eastern tube.

The 120m long, 2,000 tonne TBM will be turned in a special cavern created by the crew for contract joint venture Porr, Hinteregger & Sohne, Ostu-Stettin and Swietelsky before starting work on the eastern tube this autumn, 2018.

"Such an about-turn underground with a TBM of this size is an example of the technical feats being achieved during the construction work on the Filder Tunnel," said Martin Herrenknecht, owner and CEO of the TBM manufacturing company.

The tunnel section is located in heterogeneous rock strata and overcomes a total height difference of 155m with a slope of up to 2.5%. Due to the complex project requirements, initially no mechanized tunnelling was planned for the Filder Tunnel but client Deutsche Bahn was persuaded of the advantages of mechanized tunnelling over a large part of the route using a convertible multi-mode machine.

In the upper section of the Filder Tunnel the TBM worked in EPB mode with screw conveyor muck removal and in the lower section in open single-shield mode with belt conveyor discharge. In the geological transition zone material was removed using diggers and loosening blasting.

The Filder Tunnel is the longest on the new railway line between Stuttgart and Ulm, which will link the new central railway station with the Filder Plain. As a result of the railway project, travel times between Stuttgart and Ulm will be almost halved. Around ten million passengers per year will benefit from the scheme.

A Herrenknecht 10.8m diameter TBM is currently working on the Albvorland Tunnel and a Herrenknecht 11.3m diameter machine recently completed the 8.8km long Bossler Tunnel.

References

- Milestone advance on Stuttgart-Ulm rail links – TunnelTalk, July 2018

- Great strides at Stuttgart-Ulm rail scheme – TunnelTalk, April 2017

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.