Cost comparison for Femarnbelt link options

Nov 2010

Shani Wallis, TunnelTalk

- The numbers are in and the tunnel option has it by a nose!

- As large as the numbers are for the scope of the project, a cable-stayed bridge across the Femarn Bælt for a fixed connection between Denmark and Germany comes in at DKK 38.5 billion (about US$7 billion) while the estimate for an immersed tube across the 20km strait is DKK 37.9 billion.

-

Fig 1. Femern Fixed Link

- The estimates are in 2008 prices and compare concept options for a four-lane highway and two-track railway connection across the sea. After signing a treaty agreeing the fixed link concept in September 2008, two teams in the Danish owner organisation, Femern A/S, have been developing the conceptual designs and cost estimates of the cable-stayed bridge and immersed tube tunnel alternatives.

- A bridge has been considered the less expensive option through the process and therefore the favoured leader. Announcement of the cost estimates last week by the political parties behind the fixed link project in Denmark however produced a surprise result with the immersed tube revealing a lower estimate than the bridge. Conference presentations by leading engineers associated with the immersed tube option (at the Strait Crossings Symposium in Trondheim Norway in June 2009; at the ITA World Tunnel Congress in Vancouver in May 2010; and at the TunnelDesign & Construction Europe Conference in Zurich, October 2010) had hoped for a close run thing with the bridge coming in just below the tunnel.

- The outcome of the rival bids however demonstrates a tighter run race than predicted. Initially the there was a price difference of more than 1 billion Euro between bridge and tunnel but the bridge has turned out more expensive than anticipated and the tunnel cheaper than projected. In a press release of the announcement, Danish Minister for Transport Hans Chr. Schmidt stated that, "the cost of the two solutions is, generally speaking, the same. The repayment schedule for a bridge is 29 years and for an immersed tunnel 30 years. This confirms the project's sound financial basis."

- The result illustrates also the tremendous work achieved by the tunnel team in exploring new techniques and concepts to reduce the cost of building, operating and maintaining an undersea link and the way in which attitudes and techniques for reducing polluting substances into the atmosphere have changed and advanced.

- At the Zurich conference late last month, Susanne Kalmar Pedersen, Senior Project Director Tunnel Department of Rambøll and for the Rambøll-Arup-TEC Joint Venture selected by Femern A/S to design the tunnel alternative, described several cost saving developments, many of which could not be revealed in detail ahead of the project's cost comparison announcement last week on Tuesday 2 November.

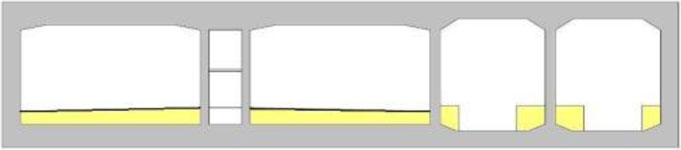

- One of the most significant savings was elimination of an intermediate man-made island design to accommodate a huge ventilation shaft and equipment installation. Projections of low traffic volumes in the initial years, together with significant and rapid technical advances in reducing toxic emissions by road vehicles have allowed the adoption of longitudinal ventilation in the long four-lane traffic tunnel. Instead of large ventilation buildings and ducts and the intermediate vent station island, ventilation fans will be installed in ceiling recesses at 400m intervals along the 20km link. This also optimizes the design of the tunnel's cross section eliminating the need for separate transverse or semi-transverse ventilation ducts. "The change also reduces the volume of concrete in the immersed tube elements by some 10%, which is a significant saving on a project of this scale," said Steen Lykke, Project Director Tunnel for Femern Bælt A/S.

-

Fig 4. One level cross section

- Several other cost and logistical advantages, as well as safety and operational benefits, developed by the experience of designing and constructing existing immersed tube projects around the world have been adopted and adapted for building the world's longest, largest, and deepest immersed tube and second longest road tunnel in the world after the 24km long Laerdal Tunnel in Norway. On the operational side of the tunnel project Lykke - who was director of the immersed tube section of the Øresund project between Denmark and Sweden and also worked on the Marmaray fixed link across the Bosphorus in Turkey - told TunnelTalk that there are several safety optimisation considerations. Among these he included cross passage doors into the parallel road and rail cells of the tunnel at 100m intervals; a maximum gradient of 1.25%, and a deluge water spraying system to provide rapid response to an in-tunnel fire.

- Following the good news that keeps the tunnel option firmly in the running as feasible and viable, the next anticipated announcement is selection of which concept to develop further. With strong support for the project from political parties in Denmark - from Venstre, Denmark's Liberal Party; the Conservative People's Party; the Social Democrats; the Danish People's Party; the Socialist People's Party; the Danish Social Liberal Party; and the Liberal Alliance - Lykke said that while no date had been given for that announcement, "it could be as early as January or February next year."

-

Innovations for the Fehmarnbelt tunnel option - TunnelTalk, May 2010

Femern Bælt fixed link options - TunnelTalk, June 2009 - Femern Bælt Fixed Link

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.