It was standing room only in the aisles in Salzburg in early October when the annual Colloquium hosted also the Eurock event of the ISRM (International Society of Rock Mechanics). Together, numbers at the annual Salzburg gathering swelled to more than 1,200 with more than 100 company booths in the sold out exhibition set across three floors of the congress centre and more than 90 papers presented across two simultaneous sessions.

With the addition of the ISRM interest, the more usual focus on underground civil engineering of the Salzburg Geocolloquium took on a different feel, with presentations taking engineers deep into underground mining operations and high onto mountain slope stabilizations.

Proceedings opened on Wednesday (7 October) with a series of seven workshops. TunnelTalk, attending as a regular representative of the media at the event over the years, joined the workshop that discussed Contractual Models. Convened by Wolfgang Wiesner of Porr Bau GmbH, and Patrick Hehenberger of Geneva, Switzerland, who has an MSc in Construction Law & Dispute Resolution from King’s College, London, the workshop discussed a broad range of topics. These included the challenges in preparing the tender documents and evaluation of bids for a contract lot on the realigned Semmering Base Tunnel in Austria and the strained relationship between Austrian procurement law and tunnel construction contracts, to a review of various types of new contracting models being adopted in different parts of the world.

There was much interest in the concept of Early Contractor Involvement as developed by the UK. Unfortunately the UK representative invited to expand on the topic at the workshop was unable to attend but an appendix in the workshop’s printed proceedings of support material includes details of the concept as adopted by the HS2 (high speed rail) project procurement team in the UK. A variation on the theme is the Optimised Contractor Involvement procurement process which was implemented for award of the substantial TBM running tunnel and station cavern contracts for the Crossrail project in London.

Geotechnical baseline reports (GBRs), a particular development of the underground construction industry in the United States, and their application within tunnelling contracts were also discussed and an extract of the Suggested Guidelines as prepared by a committee chaired by Randall Essex and published by the CI (US Construction Institute) of the ASCE (American Society of Civil Engineers), was included in the workshop proceedings. A recent Discussion Forum article on TunnelTalk by Tim Smirnoff of HDR in the USA highlights many of the points discussed in the workshop about the establishment of the actual baseline for any project and how specific a client ought to be in writing the baseline criteria.

The extensive work of the ITA (International Tunnelling and Underground Space Association) and its Working Groups on contracts and contractual procedures was also included in the workshop proceedings and discussions. Reproduced papers included a copy of the Working Group 3 ITA contractual framework checklist for subsurface construction contracts, the Working Group 19 Guidelines on contractual aspects of conventional tunnelling and an introduction to the work of Task Group 10, in collaboration with FIDIC, on development of a New Form of Contract for Tunnelling and Underground Works.

One of the most engaging presentations was by Hehenberger who described the real project disaster of a short cut-and-cover tunnelling project gone dramatically wrong. The disputed issues were tracked through a costly and drawn-out court battle, leading to an unusually insightful judgement of all the facts by the presiding judge, and ending with the fallout of the situation. As it stands currently, the £30 million project, on a 24 month construction programme, is running almost two years late and the contractor (on the losing side of the judgement) is considering its leave to appeal and the client is caught behind the cons of terminating the contract. Alternatives to the court system to resolve contractual disputes were then discussed and Hehenberger, who has sat on many a dispute board, concluded that “dispute boards, and arbitration, are no luxury but are best practice, for good reason”.

Contributing to the discussion about claim resolution a presentation by the Strabag Department of Contract Management that studied three large projects and illustrated that a large portion of claims reflect a small proportion of the total project claim amount and that conversely, only a small number of claims amount to the largest amount of total claim sum (Fig 1). To improving difficult contractual situations, the presenters suggested, somewhat controversially, that contractual deviation management could include a whole change of procedure in mid-contract, if necessary, from a remeasurement model to a cost-plus-fee model, as occurred for the Strabag contract for the Niagara water tunnel project in Canada.

A recurring theme through the full conference and among mining as well as civil engineering professionals and presenters, was the connection between rock mechanics, geomechanics (not many soil mechanics in the group) and its mechanical excavation using full-face TBMs. There is no doubt that new generation TBMs and their potential for rapid excavation grab the attention, and while the world’s hand full of TBM manufacturers are confident in the ability of added innovations to improve performance of TBMs, there was a general opinion among project owners and some contractors that more research of existing TBM methods in general is needed to provide a firm foundation on which new ideas and developments can be built.

In their presentation, for example, the members of the Strabag Contract Management, accepted that “we are in an era of high speed technical development” and that “knowledge stems from the permanent interaction between research and practice” but that, as a result of the “typical S-curve between universities and committees establishing standards and them being implemented in practice”, a wider knowledge gap exists for rapidly developing mechanised tunnelling within the development time scale of major projects than in the same period for the more well established drill+blast conventional tunnelling (Fig 2). To reduce this gap, they attest, “various experts must be engaged during the project implementation to complete research on boundary conditions” and that this has “an impact on the agreed contractual terms and construction process” through the project.

In the opening keynote presentation of the technical sessions on Thursday morning, Prof Wulf Schubert of Graz University and President of the Austrian Society of Geomechanics, also warned of the over expectation of TBM performance in light of the need for more research into the application of mechanical excavation in different rock types and conditions. Much discussion then followed in the Q&A sessions, at the booths of the TBM manufacturers, in the corridors of the exhibition and congress halls, and over the coffee and lunch breaks, about the advantage of double shield TBMs in competent rock conditions. Does the double-shield concept guarantee high production through their ability to mine and line simultaneously? Or is the concept a necessary basis of a machine that can cope with both hard rock as well as softer, less stable, conditions while at the same time providing a one-pass initial or final lining?

To collect the information, provide material for research studies and present findings to answer these questions, there are many current double-shield TBM projects in the world today, one of the largest and one of the newest being in Austria itself with three double-shield TBMs (two Wirth and one Herrenknecht) working on the long Koralm high-speed railway tunnel project between Graz and Klagenfurt and two new Robbins double shield TBMs bringing the US company’s long standing pedigree for hard rock TBM tunnelling expertise back to the European Alpine region for excavation of the 22km long GKI hydro-scheme headrace near the mountain town of Pfunds, above Innsbruck and in the neighbourhood of the Brenner Base Tunnel, which has itself used double-shield TBMs for exploratory tunnels and is sure to engage more TBMs for the main tunnel bores.

TunnelTalk made a technical visit to the GKI project in Pfunds with Robbins and to the Koralm project as part of the post conference technical tour and will report more on both shortly.

Two other major double shield TBM operations currently in the world are:

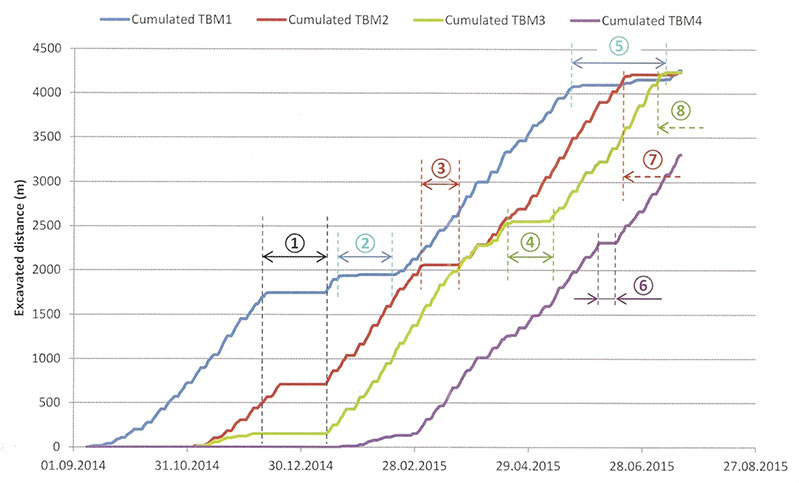

Thomas Camus, Manager of R&D at NFM Technologies, gave the last presentation of the entire proceedings on the application of the four NFM double shield TBMs on the North West rail project in Sydney. For a double shield operation, progress appeared to be below optimum, but, as Camus explained, there were many causes for interruption of excavation progress. Where double shield rates of 850m as a 30 day maximum, and near 800m as monthly averages, were recorded for the two double shield TBMs that worked on the Legacy Way highway tunnel project in Brisbane the four Sydney TBMs are being held up by the highly abrasive Hawkesbury Sandstone though which 60% of the twin tube tunnels are aligned and by the three shifts/day five days/week production schedule with maintenance only on the two weekend days each week (Fig 3). The Sydney TBMs are reported to have been working continuously in double shield mode since being launched but cutter consumption through the sandstone is predicted at between 350-690m3/disc, depending on design and supplier.

For research institutions, there is a wealth of opportunity for study and development in the field of TBM tunnelling covering not only the metallurgy and operation of disc cutters and TBM fabrication and equipment but also in the study of geomechanics and the process and ability of TBM systems to excavate rock types and conditions, as well as the ongoing exploration of contract management and development. The details of these studies will no doubt find opportunity to present results and findings at future sessions of the Salzburg Geocolloquium.

After another productive and always enjoyable conference in Salzburg, TunnelTalk sends a warm Glückauf to the organisers and everyone we met and the plan to meet again next year in October.

|

|

|

|

|