There was a sense of energy and urgency about the two-day symposium in Istanbul. Turkey is on a fast track to make up for lost time in developing metros and road tunnel infrastructure to tackle chronic urban congestion, particularly in Istanbul, and to improve connectivity across the country, address major irrigation and water conveyance needs and increase hydropower energy production.

In this rush to increase underground infrastructure Turkey is also pushing at the boundaries of possibility with successful construction of the immersed tube rail connection and the TBM double-deck bored highway tunnel under the Bosphorus and with plans for a super-diameter TBM bored tunnel under the Bosphorus for a single-tube, triple-deck highway plus metro rail undersea connection that continues to divide opinion as to its feasibility.

While TBM tunnelling, particularly for soft-ground urban metro excavations, is a topic of concentrated attention at the moment, Turkey has a longer and more confident experience of open-face NATM or sequential excavation operations. It was admitted that if the ground has good standup properties, open-face excavation is the preferred and less expensive option on shorter drives than TBM applications. But that is changing rapidly as the many civil contractors in Turkey gaining TBM experience on projects both in Turkey and on a growing portfolio of overseas projects.

It was said that up to 50 or more companies register interest for tunnel contract procurement processes with these reduced to about 20 to present bids and reduced further to final negotiation rivals. Big names in the tunnel construction sector, including Yapi Merkezi, Gülermak, Dogus, Nurol, Kalyon and Kolin working on major projects in Turkey as well as overseas in India, Dubai, Doha, Riyadh, Tanzania, Morocco, Algeria, Ethiopia, Bulgaria and Warsaw, among others in the CIS former soviet countries, the Gulf region, and North Africa.

A paper presented by engineers from Iran described the operation of NFM TBMs to complete the first underpass of the Karun River for the Tehran Metro while another from South Korea focused on the influence on stability of a critical underground junction for a double-deck NATM-excavation highway tunnel.

In the equipment and materials supply chains, major suppliers have their own local company distributors while others are one of many international suppliers represented by large local agent companies. Others are creating joint ventures with international European and North American suppliers and Turkey is an attractive market also for Iran and other countries, which have developed their own supply industries to survive international trade sanctions.

Included among the exhibitors were chemical engineering companies BASF, CEDEX from Iran, Shell, and the Euclid EGE joint venture of Turkey, each of which supply greases, hydraulic fluids and chemical based grouting agents to the underground construction industry; WJ Groundwater of the UK, experts in the control of groundwater ingress and seepage; Ampcontrol of Australia, suppliers of power transformers and generators to the tunnelling industry worldwide; Forta, suppliers of synthetic fibre; Bekaert Maccaferri Underground Solutions, suppliers of steel and synthetic fibres; and Asrin, manufacturers and suppliers of segment lining accessories among many others.

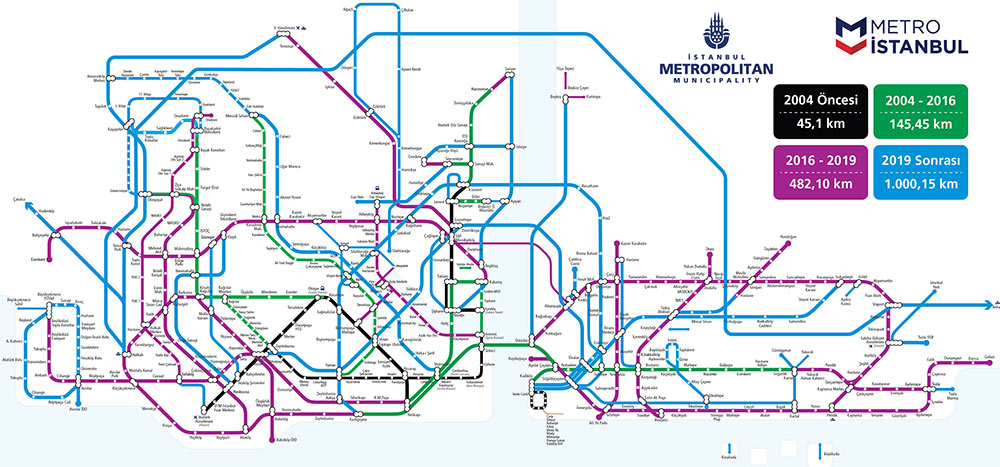

Metro accounts for the highest demand of underground construction in Turkey with new lines and extensions progressing and planned in Istanbul, Ankara and in Izmir. The most aggressive programme for metro development is in Istanbul where up to 20 or more TBMs will be operating in the city during 2018 on running tunnels for new lines and existing line extensions. The investment program is being carried out by the Istanbul Municipality Directorate of Rail System Projects.

To manage ambitious metro developments, Metro adopted 4D BIM systems to control the various aspects of construction including time. In a presentation, Ms Nurcan Kalkan and Abdelaziz Sevgin of Metro Istanbul and head of Nika Consulting, Mehmet Akif Ibrahimoglu, explained how BIM is avoiding ambiguities in contact documents, reducing the need for design revisions, assisting more accurate estimating of quantities and costs, and assisting time programming to schedule more efficiently and finish earlier.

Other papers discussed:

The application and operation of TBMs was also high on the technical session agenda. With the experience of so many different TBMs in the Istanbul metro, there was an interesting paper on the experience of the large diameter Herrenknecht TBM that excavated the Eurasia double-deck highway tunnel under the Bosphorus and another that compared the operation of three different makes of metro size TBMs on the same contract and through the same ground and with the open ratio of the EPB cutterheads as the principle difference. The large open ratio of 37% proved most effective, operating at 2-3 time less torque and consuming less energy although the need to control the larger openings with grizzly bars was emphasized.

Two symposium papers presented out-of-box proposals.

The first by Professor Ms Nuray Tokgöz of Istanbul University proposed the use of sea water as a conditioning agent in EPBM operations and the use in addition of ultrasound energy application on fine-grained clayey sedimentary deposits conditioned with sea water. It was said that this combination would prove effective and more environmentally acceptable than the chemical based conditioners currently used in EPB tunnelling.

A second paper reviewed a novel method of using microwave energy to assist the drilling and cutting of hard rock. Not a new idea, as explained by Professor Sair Kahraman of Hacettepe University of Ankara, but one that has been studied since the 1980s with results confirming that exposure to microwave radiation, samples exhibited a reduced UCS of 50% and up to 80% in samples of basalt. He reported that an experiment by Hassani et al in 2016 melted the center of a sample of rock when exposed to 120sec of microwave energy at 3kW. Many other studies have investigated to use of microwave treatment of the rock which is said to be effective to a depth of about 5cm and while in 2011 Hassani and Nekoovaght prepared the design of a microwave assisted TBM cutterhead and in 2013, Wang et al designed a microwave assisted drill bit, none have as yet manufactured a MWA (microwave assisted) prototype. Such a prototype is a research project by Kahraman and his colleagues and research student teams.

Robbins machines were the first TBMs in Turkey back in the 1960s and 1970s, with Lovat supplying the first TBMS for urban metro tunnelling for the Ankara Metro in the 1980s and Herrenknecht then making a significant contribution to TBM projects through the following 30 years.

Today new suppliers are making their mark in Turkey. Terratec and the Chinese supplies Lovsuns, which owns the Lovat intellectual property and operates from its former headquarters in Toronto; CRCHI, the TBM manufacturing division of China’s CRCC group; and CREG of China, which owns the Wirth intellectual property, all have several TBMs on order for Istanbul Metro contracts and with many more machines required in the short term of planned metro expansion. All were represented in the TunnelTurkey event exhibition.

As well as three current metro line extension projects, Istanbul is building a new international airport to the north of the city and a metro airport link of 38km of twin running tunnels and requiring 10 TBMs, is being developed for construction over the coming years by the appointed GYH (Kalyon-Kolin-Cengiz) design-build construction consortium.

As one TBM manufacturer representative in Turkey explained, it is the bottom line price that concludes a TBM sale and another admitted that where a metro TBM could demand a cost of more than €6.5 million 10 or 12 years ago, today they are being bought for less than €4 million at about €3.6-€3.8 million per machine. Another representative said that it is then the terms of the letters of credit between the banks of the manufacturer and the customer that adds to the competitive edge and in the long run, faultless service that ensure repeat and continued business. “Meeting commitments on delivery, performance and service through assemble and operation ensure customer loyalty.”

In the water industry, demand for TBMs is also high with particular challenges facing several current TBM water conveyance tunnel projects. Squeezing ground, fractured and blocky fault zone conditions, high volume and high pressure water ingress rates and kastic voids are all protential difficulties faced by long distance water tunnels and there are several TBMs stuck or defeated by such conditions in Turkey.

Feasibility of combining road and rail, in a single large diameter TBM bore, under the seabed of the Bosphorus for Istanbul divides opinion and will require “all engineering groups to come together and discuss it in combination with civil society groups” as opposed to allowing development of the project by a private concession proposal was the implication.

Another challenge causing particular concern natural gas infiltration. TBMs and entire tunnelling operations must be refitted or replaced with explosion proof machines and equipment to restart some drives and to tackle new projects.

Much of the symposium energy at the symposium was generate by the group of young civil engineering and mining university students who attended the two-day event. Their interest in the topics discussed and enthusiasm to be part of the specialized underground development industry represented an assurance that Turkey will have the talent and resources to fulfill its underground infrastructure aspirations.

In fostering those aspirations and continuing the association of the underground tunnelling industry in Turkey with the international community, the Turkish Tunnelling Society (TTS) is in a period of transformation to become a wider, more encompassing society of professionals. Hosted originally by the Ministry of Roads, the Society is expanding to welcome and include professionals in the metro, railway and water supply industries and ensure that discussions and meetings are applicable to all sectors of the industry.

It was an engaging, productive and very enjoyable event and many thanks are extended to the TTS for hosting the attendance by TunnelTalk. The next staging of the symposium is set for September 2018 and again in Istanbul.

|

|

|

|

|