Just six months after the major tunnel collapse at Rastatt in Germany, Nick Shirlaw writes to advance his comments regarding failure at the tailshields of EPBMs as the suspected cause of the fatal collapse in Foshan.

This is a rare cause of a major loss of ground over a pressurized TBM, writes Shirlaw who invites readers to add to the list of known incidents, suggesting that smaller and more numerous incidents tend to get quietly backfilled and forgotten and that even the bigger incidents tend to hit the headlines briefly, with only speculation as to causation. He asks, how can realistic risk assessments for pressurized TBM tunnelling be carried out if there is a fundamental lack of information on the frequency or cause of ground loss incidents?

See the full feedback contribution at the bottom of the article and with feedback contributions on the Rastatt collapse on the Feedback.

Add your contribution and thoughts to the discussion via our Feedback service

An inrush of water and mud through the tailseal of an EPB TBM working on the Foshan Metro Line 2 is said to have caused the devastating collapse of the heading, claiming the lives of 10 and with another still missing. Unofficial reports to TunnelTalk from contacts in China confirmed that it was inrush through the tailshield, rather than over excavation at the cutterhead, that undermined the segmental lining and led to the massive collapse, burying the TBM and its crew as a consequence.

The failure occurred at 8.40pm on the night of February 7 as the TBM was excavating the 6m diameter metro tunnel beneath the main traffic thoroughfare of Foshan city near Guangzhou in southeast China. The completed parallel running tunnel some 7m distant is unaffected by the 200m2 (30m wide x 6m deep) sinkhole over a second TBM drive. Contacts suggest that the same TBM may have excavated both running tunnels.

Nine workers in the crew were reported as surviving the incident. It is unknown if the dead and missing were all construction workers. Traffic blocks were implemented immediately to allow for rescue and recovery efforts. A reported 30,000m3 of concrete has backfilled the sinkhole and allowed traffic on the eight-lane highway to resume.

According to local newspaper and TV reports, authorities also shut off water, gas and electricity supplies near the collapse zone and report that Deputy Governor of Guangdong Province, Lin Shaochun, was among the first high officials to be at the scene.

One of the surviving workers told TV reports that he and his workmates had known something was wrong when they saw wet clay running in the tunnel. Seconds later, and after hearing a loud noise, the workers realized there was “big trouble” and started to shout warnings to run. Once on the surface, he said, it was realized that only workers near the working shaft had managed to escape. Among the missing, he said, was an assistant project manager.

Other fatal collapses have been experienced on projects that quantify the rapid expansion of metro systems in China and while China has made considerable progress in improving industrial safety, fatalities in the country's construction and tunnelling industries is still high and higher than global standards. Official figures are reported as recording 38,000 fatalities in workplace accidents in 2017 with an explosion at a high-speed rail tunnel construction site in the southwest province of Guizhou in May 2017 claiming the lives of 12 workers.

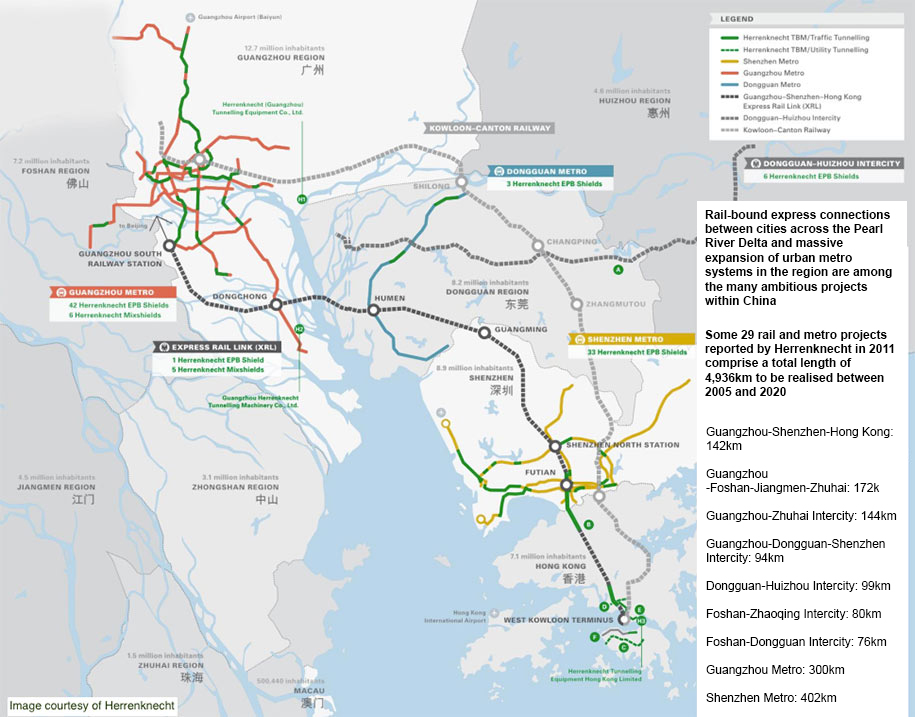

How fatalities and accidents are recorded, and how these compare with fatalities and accidents per kilometre of the astonishing lengths of tunnelling excavated in China per year, compared to other countries of the world, and across all tunnel excavation purposes, is a set of research yet to be made available. It is known that some cities build 50km or more of new metro lines within one year. By 2020, there will be some 6,000km of metro in operation in China. In the Pearl Delta alone, and for metro and intercity rail systems alone, TBM tunnelling and excavation for stations, shafts, cross-passages and crossover structures is a continuous rolling programme with many projects and contracts and tens of TBMs operating and progressing simultaneously.

TunnelTalk visited one of the first cut-and-cover metro line construction projects in Guangzhou city in 1990. Since then hundreds of kilometres of metro and rail tunnel systems have been excavated in the region.

The earliest TBMs to operate on these systems were supplied and imported from the international TBM manufacturers of the time, including Robbins and Herreneknecht. In more recent times, Chinese manufacturers have established their manufacturing capabilities and knowhow and are increasingly suppling to national projects and have the intent of supplying international projects.

In 2007, Robbins reported that the China Communication Construction Corporation, 2nd Navigation Engineering Bureau contractor (CCCC), selected two 6.3m diameter Robbins EPBMs for the twin 2.6km long rail tunnels on its Lot 12 contract for the 32km Guang-Fo line running between Guangzhou and Foshan. A further 14 TBMs from different manufacturers worked on the other 11 lots of the project.

The geology on the alignment, which included passage under the Huadi River, was reported by Robbins as a complex layered profile ranging from highly weathered to slightly weathered granite, coarse sand, and silt. Some 70% of the tunnel horizon was through a mixed face, with soft soils above spring line and the bottom half in rock of at least 50 MPa UCS. The remaining 30% consisted of flowing sand with high water content. EPB operating pressures were up to 4 bar.

The two Robbins TBMs launched in December 2008 and January 2009 respectively and brokethrough after seven months of boring. A best month advance of 377m was claimed as higher than any of the 16 TBMs that worked on the project.

In 2011, Herrenknecht reported that it had delivered 48 TBMs to the Guangzhou Metro project (Fig 1) with a further 33 on the Shenzhen Metro. At the time these projects were part of the on-going expansion of metro and rail connections between the major conurbations of the Pearl River Delta which include the islands of Hong Kong and Macau.

您当前的位置 : 浙江在线 > 时政新闻 > 国内综合 正文

广东佛山地铁工地塌陷事故遇难者增至10人

2018年02月09日 08:29:55 来源:中国新闻网 记者 程景伟

中新网佛山2月9日电(记者 程景伟)据广东省佛山市政府新闻办公室8日晚最新通报,截至2月8日晚7时05分,救援人员先后从佛山地铁2号线工地塌陷处再救出两名被困人员,但经现场诊断均已无生命体征。至此,事故中死亡人数增至10人,另有一人失联。

目前,现场指挥部仍在继续增强应急救援力量,调集专业队伍,科学实施应急救援方案,尽最大努力搜救被困人员。

现场指挥部已安排专门力量,对事故现场地表及附近建筑物沉降进行监测,并组织地质、地铁、道路交通等相关专家,现场调查论证透水来源等技术原因,研究确定应急处置方案,组织开展安全评估并切实抓好落实,全力防止次生灾害发生。

目前,结合上级安全生产督导要求,佛山市已组织开展安全生产大检查,彻底排查和消除事故隐患。救援善后工作仍在紧张进行中。

标签:佛山市;现场指挥部;地铁;新闻办公室;救援人员;生命体征 责任编辑:蒋敏华

Zhejiang Online News Guangdong Foshan subway construction site collapse accident toll to 10 China news reporter Cheng King Wai

Foshan February 9: According to the Guangdong Foshan Municipal Government Information Office on the evening of August 8, the latest update reports rescue personnel from the Foshan Metro Line 2 construction site collapse that two trapped people were recovered, but the onsite diagnosis had no vital signs. At this point, the accident death toll is 10 with another missing.

At present, the on-site command continues to mobilize the professional team to enhance emergency response efforts, implementation emergency relief programs and make the greatest efforts to rescue trapped people.

On-site command has engaged a special teams of geological, subway, road traffic and other experts to both the accident site and to buildings near the surface subsidence to monitor and manage on-site investigations and verifications of other sources of technical issues. The study has identified an emergency recovery program and the Organization for Security Assessment has effectively implement the program to do its best to prevent secondary disasters.

At present, and combined with superior safety supervision requirements, the Foshan city has organized large production safety checks to isolate and eliminate the risk.

Rescue work is still tense.

Tailshield failure as source of fatal TBM collapse in Foshan, China

Feedback from: Nick Shirlaw, Golder Associates

Just six months after the major tunnel collapse at Rastatt in Germany, TunnelTalk carries news of another major failure, at Foshan in China. Sadly, the Foshan failure has resulted in multiple fatalities.

After the Rastatt failure, I noted that the ascribed cause, of failure of the tunnel lining behind the Rastatt TBM, was very rare. However, there had been a (very) few other instances of the failure of segmental tunnel linings over the prior 18 years.

The failure at Foshan is ascribed in the article to a failure of the tail seals of an EPB TBM. Again, this is a rare cause of a major loss of ground over a pressurized TBM. I know of only two other cases over the last 18 years:

1. The failure at the Langstaff Road Trunk Sewer tunnel in Toronto, Canada in 2008, which was covered in a TunnelTalk article by P Wallis in 2009

2. A loss of ground due to failure at the tail seals over one of the EPB drives for the Singapore Deep Tunnel Sewer system(1) in February 2003. Although there was a significant loss of ground, there was no injury, nor a sinkhole. Above the tunnel was the approach ramp in Singapore to the underpass where Farrer Road passes under Holland Road. The U shaped reinforced concrete approach structure settled by 48mm as a result of the loss of ground. The incident was referred to in Shirlaw and Boone (2005).

There may have been other incidents of failure at the tail seals of which I am not aware. It would be useful if TunnelTalk readers could add to the list given above.

It is my opinion that a relatively small proportion of losses of ground over pressurized TBMs are recorded in available documentation and in professional/trade journals or newspapers. Inevitably the biggest ones are covered by the general media (as is the Foshan collapse).

TunnelTalk is doing a sterling job of making the tunnelling community aware of many of these major incidents. However, the smaller, and, in my experience much more numerous, incidents tend to get quietly backfilled and forgotten.

Even the bigger incidents tend to hit the headlines briefly, with only speculation as to causation. It is rare to get good forensic information at a later date. How can realistic risk assessments for pressurized TBM tunnelling be carried out if there is a fundamental lack of information on the frequency or cause of ground loss incidents?

Sincerely,

Nick Shirlaw,

Golder Associates

|

|

|

|

|