Hard rock TBM development in China 02 Apr 2020

Transfer of water from the Songhua River into central Jilin Province is centred on a 635km long water diversion conveyance scheme, the longest water delivery project in the history of Jilin Province.

One of the longest elements of the water transfer project is the 19.8km long x 8m diameter tunnel from the Fengman Reservoir to the left bank of the Wende River. Excavation of the tunnel through hard rock was completed using an open gripper TBM manufactured and supplied by CRCHI to the China Railway 18th Bureau Group Company as the tunnel contractor.

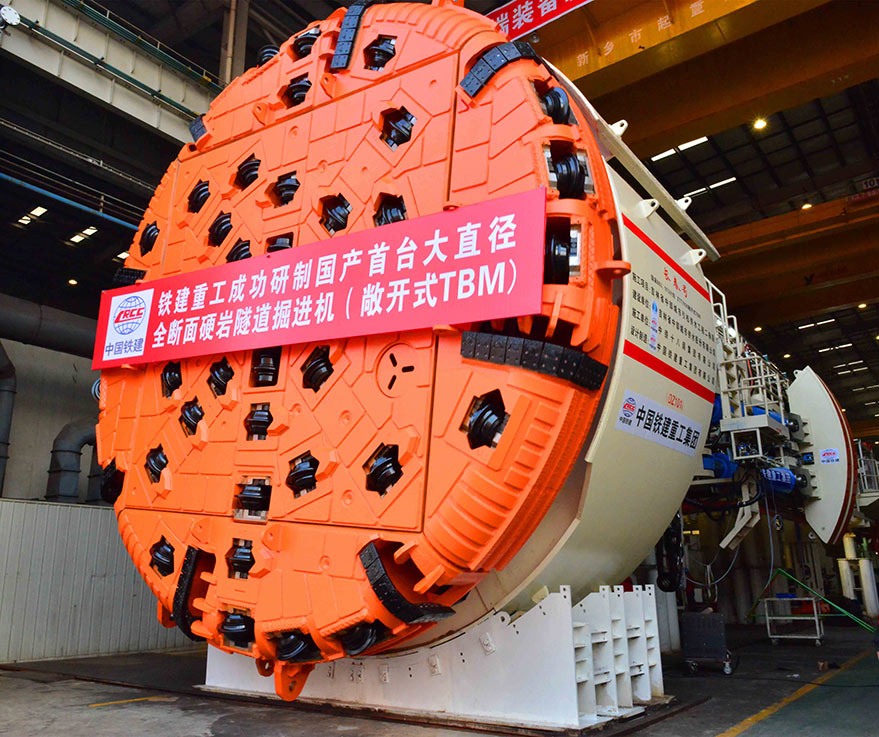

The 8m diameter CRCHI TBM is the first open gripper TBM manufactured by a Chinese manufacturer in China. The supply contract was signed with CRCHI in June of 2014 and CRCHI is leader of a research project, of which this TBM is part, into large-diameter TBM machine engineering under the National High Technology Research and Development programme of China (the 863 Programme) investigating key technologies and the application of large-diameter hard-rock TBMs.

As part of the research project a study was established to investigate the mechanism of disc cutter wear. It was based on combining simulation analysis and engineering practice with an array of wire grid and resistor sensors to monitor cutter wear. From the research project new ways of detecting cutter wear have been created and new ways of designing drive systems subjected to strong vibration have been mastered.

Problems in correcting TBM alignment were also addressed through simulation analysis. The impact of vibration on alignment was eliminated with innovative technology. It was verified that inclinator data can be preprocessed by wavelet synthesized filtering algorithms. Measurement accuracy of TBM alignment control was effectively proven.

The TBM took seven months to design and manufacture and one month to transport to the job site. After two months in assembly and commissioning, the machine was launched in March 2015.

| Table 1. 2015 monthly advance rates | |

| July | 550.0m |

| August | 558.0m |

| September | 509.0m |

| October | 736.5m |

| November | 851.0m |

| December | 1,209.8m |

The tunnel was completed in two drives, the first of 8,298m and the second of 11,499m, with each on a gentle gradient of 1:4,300 and a maximum overburden of 537m. There was mainly tuff and granite rock along the excavation with compressive strength ranging from 74MPa to 169MPa in the initial survey. It was up to a maximum of more than 200MPa in actual measurement. Some 32.8% of the alignment was in Class II rock, 56% in Class III and 11.2% in Classes IV and V.

With an installed power of 5,000kW, the TBM achieved a maximum advance rate of 120mm/min.

A maximum daily advance of 86.5m was achieved by the TBM during excavation, setting a new record in China. Monthly advance reached more than 920m in May and June 2015 when boring through rock Class III.

From July of 2015, the TBM started to excavate harder rocks with compressive strengths of more than 200MPa. It also encountered fracture zones (Table 1).

With total advance of 6,865m in six months, and an average monthly advance of 725m, the TBM has set a new record in China.

References

- Testing deep level excavation and operation in China – TunnelTalk, January 2020

- Shanghai examines underground developments – TunnelTalk, November 2011

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.