Construction of great excavations

Aug 2001

Shani Wallis, TunnelTalk

-

Beams of subatomic particles have once again started travelling at light speed around the 27km long accelerator ring of the CERN laboratory's LHC machine in search of even smaller particles of matter. Restart of the machine this week (21 November 2009), ends 14 months of work to repair electrical faults in the circuitry of the electromagnets that accelerate the beam of particles around the tunnel, which caused the shut down following its inauguration in September 2008. As the scientists hail restart of the particle smasher as a barrier breakthrough in the field of nuclear physics, this is an opportunity as well to look back and celebrate the significant civil engineering achievements that are the underground structures that house the components of the new LHC machine. TunnelTalk made a visit to the project in August 2001 to report on the challenges presented to the civil engineers and how these were addressed and accommodated.

- By any definition and from any point of view, the scale of the underground caverns being excavated near Geneva at the particle physics center run by the Conseil Europeen pour la Recherche Nucleaire (CERN) - the European Organization for Nuclear Research - is extraordinary. Add to the extraordinary scale the problematic geological conditions, the purpose of the underground structures, and the requirements of the project owner, and the excavations become truly spectacular.

- CERN is in the process of retiring its 11-year-old Large Electron Positron (LEP) collider and replacing it with the Large Hadron Collider (LHC), which will be larger and havemore power. The superconductingmagnets that will accelerate and direct a beam of subatomic particles on their circular path around the newmachine will be fitted into the existing 27km long tunnelled ring, but new underground halls are required to house the detectors and the associated computer control rooms. The detectors for the LHC collisions aremuch larger andmore complex than the LEP detectors, which are now obsolete. Cavernsmore than twice as large as any now at the CERN facilities are needed to house thesemassivemachines. The caverns now under construction are up to 35m wide, 42m high, and 82m long - positively staggering in scale.

-

Massive detector machines require huge

new caverns - Researchers at the CERN particle physics center conduct experiments to determine the composition ofmatter and the forces that hold particles ofmatter together. Supercolliders accelerate such particles as electrons, positrons, protons, and neutrinos toward one another at speeds approaching that of light. Dipolemagnets are used to keep the particlesmoving in a circle - around the ring-shaped vacuum chamber that forms the bulk of the CERN structure - and quadrupolemagnets keep the particles packed closely together as they travel. Once the particles collide, the results - such as the creation of new types of particles not found in nature - are sensed and recorded with detectors.

- The applications for this research range from discovering the secrets of the big bang to improvingmedical imaging. In fact, the World Wide Web was originally developed to facilitate collaboration and the instantaneous sharing of information by scientists working in the field of high-energy physics at various universities and institutes throughout the world.

- At present the CERN facilities comprise a group of surface installations and a network of underground installations that cover a wide area straddling the Swiss-French border west of Geneva. The underground facilities house linear and circular accelerators. The largest of these are the two principal circular accelerators: the 9km tunnel ring of the Super Proton Synchrotron (SPS) preaccelerator and the 27km ring formed by a 4m diameter concrete-lined tunnel built in the 1980s for the LEP accelerator. Four large detectors were built into underground caverns on the 27km LEP accelerator. These caverns, as well as their adjacent service and computer control rooms, are linked to surface offices and workshops via access shafts. The underground location of the accelerators, built asmuch as 100m below ground, serves two purposes: first, there is sufficient space for building these complex structures, and second, any radiation generated by the accelerated particles and the experimental particle collisions is isolated.

- The construction program for the new facilities required for the LHC - which are being incorporated into the existing LEP and SPS rings - divides the work into three segments. And while the new superconductingmagnets will be installed in the existing LEP tunnel ring (saving an enormous amount of money), the huge caverns for the two newmassive LHC detectors - dubbed ATLAS, a toroidal LHC apparatus, and CMS, a compactmuon solenoid - are located at two new Points on the LEP ring. The ATLAS facilities, grouped into segment 1 of the construction program, are at Point 1 on the ring (Fig 1), and the facilities for the CMS detector, which will be built as part of segment 2, are at Point 5, which is on the opposite side of the ring. The work involved in segment 3 encompasses necessarymodifications to the existing structures on the LEP accelerator ring and provides new tunnel connections between the LEP ring and the SPS ring. Segment 3 was divided into two sections: 3A and 3B. The 3B contract is for the TI8 tunnel link between the smaller and the larger accelerator rings near Point 1 and all other necessarymodifications to existing structures; the 3A contract includes the TI2 link.

-

Fig 1. Design on the new elements to be built into the existing accelerator tunnel ring for the new

LHC machine - The decision to replace the LEP collider with the highpowered LHC wasmade in 1994, when the council representing the 20member states of the CERN organization committed itself to investing SFr3 billion (US$1.7 billion). With the commitment came the goals of decommissioning the LEPmachine by the end of 2000 and having the LHC operational by early 2006. The civil engineering work amounts to about SFr350million (US$197million), or about 12% of the full investment. In addition to incorporating the new structures into the existing underground structures, CERN physicists wanted the large caverns positioned as closely together as possible in order to limit the distance between the detectors and the data-collecting computers, said Timothy Watson, the Deputy Group Leader of CERN's in-house civil engineering group.The shafts have an average depth of 100m and range in diameter from 12m to 22m.

-

Shafts of 12m to 22m diameter are needed to access the new underground facilities

- The components of the massive detector machines and lengths of the new superconducting magnets will be lowered into the underground structures through the larger shafts. CERN physicists also identified the Points on the ring at which they wanted these massive caverns and shafts. The geology at CERN is far from ideal for such large excavations. The existing underground facilities lie in the sedimentary deposits of the Geneva Basin between the base of the Jura mountain range in Switzerland to the north of the Alps and Pre-Alps to the south in France. If these caverns were being built for any other facility and for any other purpose, they would be moved, realigned, and repositioned to ensure a location within the best possible geology. The space between adjacent caverns would certainly be increased to maximize stability and limit the influence of one excavation on the other. "Here at CERN we didn't have the luxury of either," Watson said. "We had to work to the cavern parameters required by the physicists and in the geology at the given Points on the existing accelerator ring."

- The existing underground structures lie in the sandstone and marl of the Tertiary molasse deposits of the Geneva Basin, which by accident rather than design are favorable for the tunnels and the smaller caverns of the LEP machine. When CERN was established in the 1950s, the geology and its suitability for large underground excavations were not of primary concern. Early experiments were conducted in shallow underground facilities excavated by cut-and-cover construction. The scale of the underground facilities that would become necessary with time was hardly imagined back then.

- Geneva was chosen for the CERN site in the early 1950s primarily because the Swiss government donated the land to establish the facility there. Geneva is centrally located within Europe and there is an international airport nearby. Also the nature of the organization during its formative years was such that placing the headquarters in a politically neutral country was deemed advisable. Under the current political climate, 13 of the 15 European Union countries, all but Luxembourg and Ireland are among CERN's 20member states, as are Bulgaria, the Czech Republic, Hungary, Norway, Poland, Slovakia, and Switzerland. Organizations such as universities, government departments, and science laboratories from companies that are not members of CERN may also use the nonprofit, noncommercial facility. The largest nonmember users of the facility are Russia and the United States. Nearly 600 physicists from each nation work at CERN at different times. CERN itself employs a staff of about 2,700: physicists, engineers, computer experts, and administrative personnel.

- CERN's budget is determined each year by the national governments of the member nations. It is then split into contributions from each government based on a percentage of each country's gross domestic product. CERN's annual budget at present is about SFr1 billion (US$560 million), and despite the proportional system of funding each member state has an equal voice on the decision-making council.

- Table 1. Design and construction groups engaged on the LHC civil works

| Construction Package | Design Enginners | Civil Contractor | Contract Values |

| Package 1 Point 1 - Atlas Machine installation caverns and access shafts. |

A joint venture of EDF - Electricité de France (France) and Knight Piésold (UK) |

A joint venture of Zschokke Locher (Switzerland) C Baresel (Germany) and Porr-Asdag Tunnelbau (Austria) |

Sfr 80 million (US$45.7 million) |

| Package 2 Point 5 - CMS Machine installation caverns and access shafts. |

A joint venture of Gibb (UK) Geoconsult (Austria) SGI (Switzerland) |

A joint venture of Dragados (Spain) Seli (Italy) |

Sfr 113 million (US$64.5 million) |

| Package 3 Associated Structures in Package 3A and the T18 connections tunnel of Package 3B |

A joint venture of Brown & Root (UK) Intecsa (Spain) Hydrotechnica Protuguesa (Portugal) |

Contract 3A - a joint venture of Taylor-Woodrow (UK) AMEC (UK) Spie-Batignolles (France) Contract 3B - a Swiss joint venture of Scrasa/Prader/Losinger |

Sfr 100 million (US$57 million) Sfr 23 million (US$13 million) |

- After completing the planning and preliminary design stages of the three construction segments, the CERN engineering team invited consulting engineers from the member nations to submit proposals for the detailed design contracts. "It is CERN's policy to source design, construction, and other services from member nations only," Watson says. CERN selected a design group for each segment in April 1996. Documents for the construction contracts were then released in March 1997. Thirteen international joint venture groups submitted bids for one or all three segments. Contracts were then awarded based on technical ability, experience, and price.

-

Fig 2. Design of the largest Atlas cavern complex

- According to Watson, the location of each facility on the existing accelerator ring represented a concession made by the physicists. "They would have liked to have had CMS at Point 1 and ATLAS at Point 5. We convinced them, however, that it would be better to place the largest caverns in the more geologically competent of the two locations." At Point 1, the upper layer of water-bearing Quaternary moraine is 5m to 10m deep compared with Point 5, where moraine extends for about 55m before interfacing with the more competent, practically impermeable molasse.

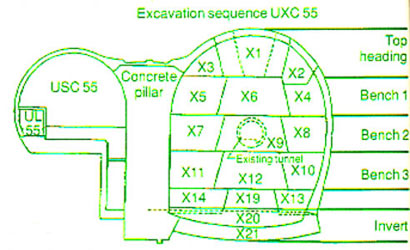

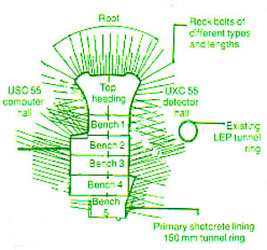

- The two caverns for ATLAS at Point 1 lie perpendicular to each other between 60m and 100m below the surface (Fig 2). The detector hall is in line with the LEP ring tunnel, the alignment passing through at about mid level. A heavily reinforced 2m thick concrete wall separates the service computer hall and the detector hall to provide the minimum distance for computer links and to protect physicists and personnel in the computer hall from radiation generated by the experiments.

- There are only a few caverns in the world with spans larger than that of the detector hall at ATLAS. One of them is the 60m wide freestanding span excavated in hard granite rock for the underground ice hockey cavern in Lillehammer, Norway. Another cavern of impressive proportions in sedimentary rock as weak as that found at CERN is the crossover chamber on the Eurotunnel railway beneath the English Channel. But at 22m, this span is considerably smaller than the ATLAS detector hall.

-

Comparison of Cern caverns with the UK channel Tunnel Crossover cavern

- Although the Molasse at Point 1 is relatively competent, it is highly heterogeneous, comprising continually variable sequences of marl and sandstone with unconfined compressive strengths ranging 3-50MPa. "Creating successfully huge open spaces in these conditions is a significant challenge," said Steven Heard, the Deputy Project Manager for the Segment 1 design and site supervision team. "A great deal of computer modeling, using two- and three-dimensional programs, was used during design to determine the most appropriate excavation sequence and construction method."

- Of principal concern are the stresses and displacements that will be created in the weak to medium-strength rock around the caverns as excavation progresses. For example, as excavation of the detector hall benches down, the surrounding rock tends to move toward the new excavation, thereby inducing stresses in the recently constructed linings. The earlier concrete-lined shafts, which are connected to the vault concrete, act as huge support dowels through the rock, and the concrete lining of the cavern vaults helps to reduce ground movements, Heard said. He pointed out, however, that "the predicted stresses and ground movements influenced the method and sequence of excavation significantly."

- As requested by CERN, work on the 21m span computer hall started first in order to have it completed 18 months before the larger (35m span) detector hall. As a consequence, once the existing shaft in the complex was lined with concrete, the 104m2 vault face of the full 338m2 cavern profile was excavated in two top headings and two subsequent bench excavations. To avoid deterioration of the ground characteristics when exposed to the atmosphere, all surfaces were covered with an initial layer of shotcrete within 12 hours of being excavated.

-

The ceiling of the 35m span ATLAS cavern 'hangs' from a system of ground anchors

- A geotextile waterproofing membrane is being installed behind the concrete lining for all of the underground work. The 600mm thick in situ concrete lining in the computer hall at ATLAS is also heavily reinforced with steel rebar, particularly at the end near the detector hall and in the adjoining wall.

- In addition to the membrane system, the designers have inserted a compressible layer between certain areas of the concrete lining and the primary rock support. Inserting the layer involves systematic rock bolting and layers of steel-fiber reinforced wet-mix shotcrete. This compressible layer, comprising 100mm thick sheets of material similar to polystyrene, will allow for stress relaxation movement in the surrounding rock without placing extra load on the lining. This will be particularly useful during the benched excavation of the adjoining detector cavern.

- The two shafts that provide access to the detector cavern are 20m and 14.5m in diameter. Once work had been completed on a slip-formed concrete lining, excavation of the huge (1,380m2) cavern started with a 375m2 vault section. Again this followed a sequence of top heading drifts and benches and took excavation of the 42m high x 56m long cavern down to the gantry crane corbel level. The reinforced-concrete corbel along each side of the cavern is now complete, and it is onto this that the lining of the vault is being cast.

-

Computer hall at the ATLAS facility

- According to Heard, the span of the larger cavern pushed the limits of construction in the sandstone and marl of the molasse. Sophisticated modeling indicated that even with a dense pattern of rock bolts and thick layers of steel-fiber reinforced shotcrete, the stability of the 35m wide vault, with its heavily reinforced in situ concrete lining, would be tested severely-particularly as the benches of the excavation progressed past the alignment of the excavated computer cavern, attached at right angles, and to a full 42m depth.

- To overcome these stability concerns, the engineering and construction team decided to 'hang' the vault on a system of ground anchors installed from galleries excavated laterally from the two access shafts, about 15m above the cavern roof. From these short stub tunnels, anchor holes were drilled and the tensioned ties threaded through them. Each anchor comprises a bundle of 13 steel cables. These are installed in a systematic pattern to give a total of 38 ground anchors across the 56m long vault. Each pretensioned anchor has a 225mg working capacity and acts in conjunction with the shaft lining to temporarily support the cavern vault lining. The anchors are tensioned from within the galleries above, and banks of geotechnical instruments installed around the cavern to monitor movement and increases in ground load, including extensometers and pressure cells, will indicate how the anchors will need to be managed with time. Only when the excavation is complete and the underground spaces are finished, with their heavily reinforced concrete walls extending to the underside of the crane corbel, will the tension ties be relaxed. All movement will gradually cease over time, and the ground stresses around the new structures will become stable and in balance once again.

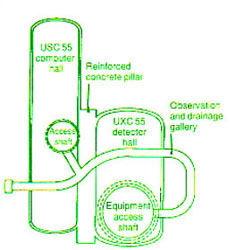

- A significant geological impact on the planned construction was encountered at Point 5 during excavation of the access shafts of the CMS facility. The design called for the use of ground freezing to support excavation of the shafts through the water-bearing moraine at the base of the Jura range. Unfortunately-and despite a program of grout injection prior to freezing in order to reduce the permeability of the moraine-the volume of groundwater was greater than anticipated. Of greater significance, the flow through the highly permeable material - particularly through the narrowing channels as the ground began to freeze - was also higher than expected.

-

Fig 3. CMS, Point 5

- As a result, the original freezing installation had to be augmented. Additional freeze pipes and grout holes were placed around the shaft circumference, and liquid nitrogen was introduced to boost the brine freezing systems. This secured a ring of frozen ground and allowed safe excavation of the shafts to the molasse interface.

- At Point 5, excavation of the caverns and shafts for the CMS machine is complicated once again by the sheer size of the caverns, their very limited distance apart, and the generally poor geological conditions. At this location, the upper waterbearing glacial moraine extends 55m and limits cover in the molasse above the caverns to about 20m. To cope with the stresses developed during excavation under these conditions, the cavern end walls are curved rather than straight to create an inherently more stable, circular profile on all sides (Fig 3). Despite this, computer modeling confirmed that excavation of the two caverns so close together could not be supported on such a narrow pillar of rock. "The solution, before any cavern excavation could begin, was to excavate this pillar zone and replace it with mass concrete," says Ken Cole, the engineer's on-site representative for the design and construction supervision team.

- The contractor excavated the full extent of the pillar before backfilling with concrete in 2m lifts. The walls and crown of the 7m thick, 31m high and 50m long pillar excavation are heavily supported with 8m long fiberglass and steel dowels and layers of 30N/mm2 steel-fiber-reinforced shotcrete. The wet mix shotcrete is dosed with 40kg/m3 of steel fiber and a nonalkali liquid accelerator is introduced to the sprayed concrete at the nozzle. A geotextile waterproofing membrane system is also being applied to selected surfaces in the pillar area before it is backfilled with concrete. The shotcrete and the membranes in the pillar excavation will be linked into the two adjacent cavern while rockbolts extending into the profile of the caverns will be cut out during excavation.

- Since the LEP machine was decommissioned in early 2001, tunnelling has progressed according to schedule. On contract 3A, excavation by roadheader of the 2.6km long x 3.8m o.d. T12 tunnel in both directions from the intermediate oval-shaped access shaft is complete and the in-situ concrete lining is in progress. On contract 3B, the Swiss construction joint venture has completed excavation of the 2.5km long TI8 tunnel using a 3.6m diameter Robbins TBM. Excavation at all other sites is by mechanical means - including roadheaders, excavators, and hydraulic hammers. Drilling and blasting are not necessary in the underlying soft to medium molasse or in the upper moraine, and care had to be taken at all times not to disturb or damage existing structures, particularly when the LEPmachine was still in operation.

Excavation, waterproofing membrane installation, and concrete lining of the new sections of accelerator

ring tunnel

- Two particular geological problems were experienced during excavation of the TI2 and TI8 tunnel structures. First there were isolated rockfalls as in situ stresses in the over consolidated molasse were released with excavation. In the smaller diameter tunnels these were not serious and caused no injuries but they did slow progress. Second, there was a swelling or heaving reaction of certain clays and marls when in contact with water introduced by the excavation process. Invert heave of as much as 300mm was subsequently reexcavated and leveled prior to being lined with concrete. Rockfalls were minimized with the installation of extra rock bolts in certain areas and with a thickening of the shotcrete primary support.

- Meanwhile, in new facilities on the surface, the components of the massive detector machines and the sections of the electromagnets to be installed in the tunnels and the set of complex, massive, and extremely impressive underground chambers are being assembled and prepared for installation. The project is on track to have all excavation completed by mid-2003 and the new LHC machine in operation by the due date of early 2006.

-

Underground triumph at CERN - TunnelTalk, Sep 2008

CERN

Gallery

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.