Both TBMs remain on hold in Perth 12 Apr 2018

Both TBMs working on the 8km long Forrestfield-Airport link in Perth, Western Australia remain on hold while investigation into two incidences of ground disturbance that created a 1m depression on the surface above the cutterhead of the leading TBM continue.

Fig 1. Details of the mulit-mode TBMs procured by the JV for the project

From the project’s media relations department

News from Perth from the client, is that both machines are under Perth Airport Estate property and came to a stop at 1,630m and 1,590m into their respective drives on 14 February and 28 March and after being launched by the Salini Impregilo-NRW JV in July and September 2017 respectively.

The TBMs were procured by the contracting JV from Herrenknecht and are described as multi-mode Mixshields capable of operating in EPB and slurry mode with material from the excavation chamber being delivered by the screw conveyor into a rotary crusher for break down into a mixture for transfer from the slurry box via the slurry transport circuit to the slurry treatment plant on the surface (Fig 1).

Both machines are confirmed as being launched from Forrestfield in the slurry mode and operating in the slurry mode for passing through the non-cohesive sand and gravel materials of the Ascot Formation funder Perth Airport. The EPM mode will be used through for clay and alluvial muds that are to be encountered as the drives pass under the Swan Review ahead of final breakthroughs at the Bayswater Junction transition ramp where services will join surface tracks for the link to Perth’s central railway station.

An independent TBM tunnelling expert and specialist advisers from Herrenknecht are working with the JV and the client’s project team to review tunnelling procedures and incorporate revised TBM operations to ensure secure progress through the complex geological conditions under the airport. The Ascot Formation was predicted during the project development stages as presenting challenging conditions.

The trailing TBM experienced no ground disturbance issues and dates for resuming advance is still as yet unknown after reports last week that it is anticipated within the coming weeks.

References

- Both TBM drives for Perth airport link on hold – TunnelTalk, April 2018

- Variable density TBMs ordered for Perth airport link – TunnelTalk, March 2017

Both TBM drives for Perth airport link on hold 05 Apr 2018

Both TBMs working on the 8km long Forrestfield-Airport link in Perth, Western Australia, are on hold. The trailing TBM in the parallel drive of the new rail link was stopped on 28 March as it came within 40m of the lead TBM which has been on hold since 14 February to investigate what has been described by project authorities as two incidences of ground disturbance.

The lead TBM had entered the airport precinct and was passing through the Ascot formation of non-cohesive granular material when two incidences of detected ground disturbance caused excavation to be suspended. According to information from the project owner, the disturbances were reported by project management staff to the contractor and took the form of surface depressions of about a metre deep in the vicinity of the cutterhead.

Both machines are multi-mode variable density TBMs and were specified by the client for the project

Photo supplied by WA Government

Although confirmed as distant from critical infrastructure and of no risk to the public, the incidences were cause for the lead TBM operation to be stopped by the contractor and for the airport and project owner authorities to suspend further advance until the occurrences had been thoroughly investigated.

An independent TBM tunnelling expert has been engaged and specialist advisers from the TBM manufacturer are on site to review tunnelling procedures and ensure any lessons to be learned are incorporated into operations.

The trailing TBM had not experienced the same ground disturbance issues but was stopped in accordance with widely-accepted best practice that two TBMs should not overtake each other or work in parallel or be halted side-by-side.

Owner of the project, the Public Transport Authority (PTA), together with the contractor, the Salini Impregilio-NRW JV, and the Perth Airport operator, are working together to allow full tunnelling operations to resume as soon as possible.

The two TBMs on the project are supplied by Herrenknecht and are of the variable density design. TunnelTalk reported when the TBMs were ordered in early 2017 that variable density machines (VD TBMs) were specified for the project by the owner PTA after seeing the technology in operation through complex ground conditions on the running tunnels of the Kuala Lumpur metro project in Malaysia.

The VD multi-mode TBM system was developed in Kuala Lumpur to operate in various combinations of EPB and slurry excavation techniques. Fitted with both slurry systems and to mix and feed a higher density bentonite slurry through the circuit, as well as an EPB screw conveyor and the availability to use a continuous conveyor to haul material through the tunnel in the EPB mode, was developed to cope with complex and variable geological conditions experiences on TBM tunnelling projects beneath Kuala Lumpur.

The higher density bentonite slurry provides a more secure cake of benonite face-support and helps prevent slurry loss from the excavation chamber of the pressurised TBM operation, using the slurry pipeline circuit to convey excavated material back to the slurry separation plant and recycling units on the surface. The technology further allows for ready conversion to EPB mode in more consolidated ground, with the excavated material passing through the screw conveyor and onto the continuous conveyor for transport to the surface for onward disposal.

In Perth, the two machines are described as multi-mode TBMs with variable-density technology and are required to operate in the slurry mode for reaches through sedimentary sands and granular materials expected on the alignment under the airport and in EPB mode through the rocky geology under the Swan River. The two machines were launched from the Forrestfield working site in July and September 2017 to advance under the airport to an underground station under the new central airport terminal and up to 26m deep under the Swan River towards a breakthrough at the transition ramp at Bayswater Junction (Fig 2). Segments are transported into the TBMs via wheel-bound mulit-service vehicles.

As well as successful operation of the VDM technology in Kuala Lumpur, a Herrenknecht VD machine was recently used successfully for a shallow metro drive over the top of the previously Mixshield excavated parallel tunnel on the Shatin Central Metro Line project in Hong Kong.

The two TBMs in Perth "have been specifically designed for the Forrestfield project by Herrenknecht,” said Public Transport Authority spokesman David Hynes. “Perth presents challenging geological conditions for tunnelling, with some elements of uncertainty to be expected in adapting the TBMs to varying ground conditions. The non-cohesive granular material of the Ascot Formation, through which the TBMs were tunnelling when the disturbances occurred, makes tunnelling more complex. This is the first time tunnelling has occurred in the Ascot Formation and it was always known that this would present challenges.”

TBM tunnelling is expected to resume in the coming weeks once a number of investigations into the incidences are complete. In the meantime, work continues on construction of the project’s Airport Central underground station and on the transition portal structure at Bayswater Junction to join existing surface rail tracks into the city's central railway station.

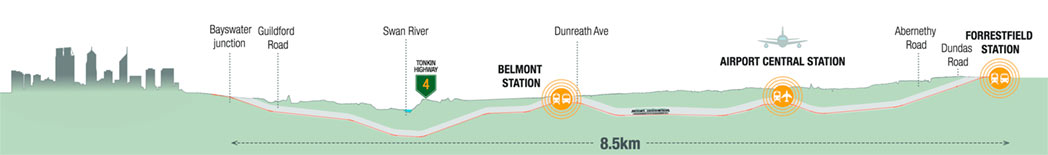

The AUS$1.86 billion Forrestfield-Airport Link will provide a new rail service from the city centre to the new airport terminal and on to eastern suburbs of Perth with new stations at Redcliffe, Airport Central and Forrestfield (Fig 1). The AUS$1.176 billion lump sum design-build construction contract, which includes a ten year maintenance period from once the project is complete in 2020, was awarded to the Salini Impregilo-NRW JV in April 2016. TBM tunnelling was schedule to take two years and be complete with breakthroughs at the Bayswater Junction transition ramp in April and June 2019.

References

- First VDM prepares for launch in Perth – TunnelTalk, July 2017

- Variable density TBMs ordered for Perth airport link – TunnelTalk, March 2017

- Perth Forrestfield–Airport link award – TunnelTalk, February 2016

- Variable density TBM on song in Hong Kong – TunnelTalk, March 2017

- New design TBM tames the Kuala Lumpur karst – TunnelTalk, January 2014

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.