Current and planned tunnelling activity in India

Jul 2008

By Shani Wallis, Editor

- Next to China, India is one of the fastest growing markets for tunnel construction over the coming years. The country has major needs for tunnelled infrastructure to improve and expand urban water supply and sewerage, bring on line more of its vast hydropower potential in the Himalayas, improve road and railway connections across the country, and realise ambitious programmes for building and expanding mass rapid transit systems.

- The economic wealth of India has increased dramatically over the recent boom in globalization. Its ability to invest in public works has increased substantially. The country has a well-established and experienced base of national tunnelling contractors and state rail, hydro and water supply authorities have experience in managing and procuring major tunnelling projects. Foreign expertise is invited for BOOT concession projects, for specialized tunnel design, construction and project management know-how, and for procurement of state-of-the- art equipment and materials supply. Opportunities for international consultants, machine manufacturers and suppliers are present and expanding.

-

Fig 1. Phases I (red lines) and II (green lines) of the Delhi Metro and its airport metro rail link (blue line)

-

Delhi mass transit

Delhi is the centre of greatest tunnelling activity at present. As well as working on an extensive 121km Phase II expansion of its metro system (green lines on Fig 1), the city is constructing the 19km long metro rail express link to connect the airport with the city centre at the Rajiv Chowk underground station at Connaught Place in the business district, through to the main New Delhi Railway Station (blue line on Fig 1). The estimated Rs 3,800cr (approx US$900 million) airport metro express line (AMEL) and much of the Phase II metro extensions are planned to be in operation by July 2010 when the city hosts the international Commonwealth Games. - Extensive sections of both lines are underground. The plan is for 14 TBMs, along with lengths of NATM excavation, sections of cut-and-cover work, and stretches of elevated guideway construction progressing concurrently during 2008 and 2009.

- Earlier this year, the Delhi Metro Rail Corporation (DMRC), a joint stock company between the National Government of India and of the State Government of New Delhi and charged with procuring both projects, awarded a 30-year BOOT concession to build, own, and operate the airport link project to the Reliance Energy- CAF Consortium. Reliance Energy, formally Bombay Suburban Electric Supply (BSES), is part of the Reliance- Anil Dhirubhai Ambani Group, one of India's largest conglomerates, and CAF is Spain's leading rolling stock manufacturer. In turn, the concession has awarded a contract to engineer and manage procurement, installation, testing and commissioning of all the electrical and mechanical systems to Hong Kong's MRT (Mass Rapid Transit) Corp. For the project, DMRC is taking general advisory services from a joint venture comprising Pacific Consultants International of Japan, Japan Railway Technical Services, Tonichi Engineering of Japan, India's RITES rail authority and Parsons Brinckerhoff.

- Three underground contracts are awarded on the 22.7km long airport link. One for the 3.7km of twin-tube bored tunnels from New Delhi Railway Station to Shivaji and two underground stations, is awarded to the international joint venture of Alpine Mayreder (Austria), Hindustan Construction Co, HCC (India), and Samsung (Korea). The JV will use two Herrenknecht EPB TBMs on the contract. Under a second contract, Alpine Mayreder with HCC, will design and construction the next 2.6km of the line as a 10m diameter single-tube, double-track NATM tunnel. The third contract is for a total 2.5km stretch of 1.7km twin tube TBM bored tunnel and 800m of open cut work into the Airport. It is awarded to the Shanghai Urban Construction Corp (China) in JV with Laren & Toubro, L&T, (India). Another two Herrenknecht EPBMs are to work on the contract.

-

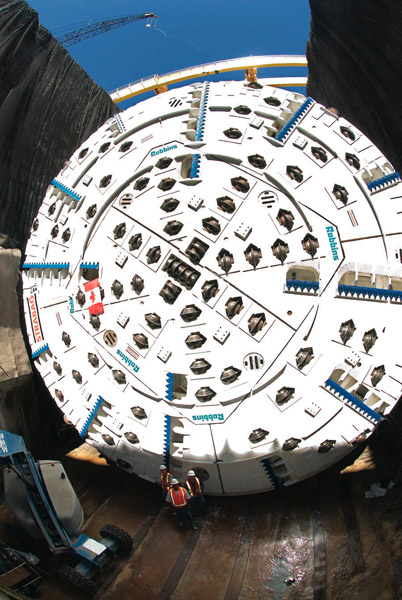

The Robbins/MHI machines feature a 55% cutterhead opening ratio for a smooth flow of muck and reduced clogging

- The first TBM breakthrough for Phase II Metro extension occurred on 31st May 2008. The Herrenknecht machine broke through at Hauz Khas after completing a 1,450m run from the Malviya Nagar shaft on the extension between Central Secretariat Station and Huda City Centre Station in Haryana State. The TBM was used previously on the first section of bored tunnels on Phase I in the centre of the city. The same JV, led by Dywidag International, is using the TBM on the Phase II project and on 19th June, the second reused Herrenknecht TBM completed the parallel running tunnel to breakthrough at Hauz Khas.

- On an adjacent contract, to the north, the joint venture of Continental Engineering Corporation (CEC Taiwan) and Soma Enterprise Ltd (India) has launched two Robbins EPB machines to work from the cut-and- cover station at Jor Bagh to complete a 2km long section of twin tube running tunnels between the Green Park and Udyog Bhawan Stations. The two 6.5m diameter Robbins EPB machines were built at Robbins facilities in China, from components designed and manufactured, in cooperation with MHI (Mitsubishi Heavy Industries), in Japan, China and USA. The Robbins TBMs are fitted with different types of tungsten carbide cutting tools and a 55% cutterhead opening ratio allows a smooth flow of muck to avoid clogging while excavating sandy silt, silty sand and gravels. The TBMs are working under ground water pressures of up to 3 bar. All the TBM bored tunnels are lined with bolted and gasketed precast concrete segments.

- In the opposite direction, the JV will use two Herrenknecht TBMs to complete the 5.3km long section. Another four Herrenknecht EPB machines are to be delivered later this year to the Ital Thai Developments/ITD CEM JV for its Phase II Delhi Metro contract. In spring 2008, Herrenknecht opened a new assembly plant in Chennai on India's eastern coast. The 3,000m2 facility will include an assembly hall, production plant for the manufacture of cutter disks and a storage warehouse for spare parts. The plant will service the eight EPB shields the company is delivering to the Delhi Metro for construction of some 18km of new metro running tunnels as well as future orders for Herrenknecht TBMs in India.

- Having completed Phase I of the system (comprising 65.11km of route length with 13km underground) and with Phase II for 121.8km and 79 stations in construction, there are plans for Phases III (112km) and IV (108.5km) to be completed by 2015 and 2020 respectively. The network will then span more than 413 route kilometres. Extensions of the lines deeper into neighbouring states are then possible for the distant future.

-

Other metro plans

There are also plans for metro systems in other cities in India including Agra, Ahmedabad, Chennai, Kochi, Hyderabad, and Chandigarh. In Mumbai, the Reliance Anil Dhirubhai Ambani Group is already implementing the first 12km from Versova to Ghatkopar in association with Mumbai Metropolitan Region Development Authority (MMRDA) and work has started also on the first line of a metro system in Bangalore. Kolkata, home of the first metro in India, is currently in talks with the Japan Bank of International Cooperation (JBIC) to fund construction of the first 9km of a proposed 19km east-west extension under the River Hooghly in bored tunnels to Howrah as a follow on to its first 16.5km north-south line. -

Central irrigation and water supply project

One of the largest tunnelling projects in the country is the Alimineti Madhava Reddy (AMR) project to bring water from the existing Srisailam Reservoir to the dry arid plains of the Nalgonda District of Andhra Pradesh. Central to the project is a 43.5km tunnel that is to be driven from each portal towards a mid-alignment junction by two 10m diameter double shield Robbins TBMs.

-

On site construction of the 10m diameter Robbins double shield TBM for the 43.5km long AMR water project tunnel in Andhra Pradesh

-

Cutterhead turning celebrations

- Under the largest ever single TBM order, signed in May 2006, project contractor Jaiprakash Associates Ltd, contracted Robbins to supply the two 10m diameter TBMs and all related equipment, including conveyors, spares and cutters, and teams of key personnel for the approximate five-year contract.

- In March this year, the project recorded a first major milestone with the cutterhead turning ceremony for the first of the two machines. Onsite assembly, rather than pre-assembly in a manufacturing facility, and as proven on previous projects, saved substantial time and money to the contract. Crews worked 24 hours a day to accomplish assembly within the aggressive four months schedule. The second Robbins machine will be assembled onsite later in 2008 and launched from the opposite end, at the inlet portal. After excavation, a drill+blast chamber will be used for removal of each TBM and back-up.

- Both machines feature back-loading 20in cutters for longer cutter life through the zones of hard quartzite of up to 450 MPa in UCS, layered and separated with shale for about 50% the drive with the remainder passing through granite of 160 to 190 MPa. The double shield machines will erect a precast concrete segmental lining as they progress. The entire project is expected to take about 60 months to complete, and should be operational by December 2012.

- Robbins is to supply two more TBMs to different water supply tunnels in the same area. The next is another 10m diameter double shield machine for the Pula Subbaiah Veligonda project that will again tap the Srisailam Reservoir on its right bank and bring irrigation water to different parts of Andhra Pradesh state. On-site assembly of the machine is scheduled to start early next year (2009). On a parallel drive for the same Veligonda project, a smaller 8m diameter double shield machine from Herrenknecht is excavating a 18.8km long heading through hard rock beneath a protected nature reserve. In addition to the TBM, Herrenknecht supplied the segment lining production facility and technical on-site support.

-

The fourth Robbins TBM to the area is confirmed in recent days and delivery of components for on-site assembly is yet to be announced. The new tunnel will also tap the vast Srisailam Reservoir as part of the Sleemanabad Carrier Canal project in the Narmado Valley in Andhra Pradesh.

http://www.therobbinscompany.com

-

Hydropower country: The Dhauliganga Valley in the Himalayas

-

Hydro power development in the Himalayas

Of many hydropower projects underway in India, those awarded most recently include the Tapovan-Vishnugad plant in the Chamoli district of Uttaranchal state in the southern Himalayas. Excavation of the 11.3km long x 5.4m diameter drill+blast headrace tunnel is awarded to the Alpine Meyreder/Hindustan Construction Company (HCC) Joint Venture for a contract value of EUR 79 million. The run-of-the-river project, fed by a barrage on the Dhauliganga tributary of the Alaknanda River, also includes an underground powerhouse, to accommodate four 130MW Francis turbines, two pressure shafts, four penstocks and a short tailrace tunnel. - HCC is also awarded Lot - IV of the Teesta Hydro Electro Power Project Stage - VI by M/s Lanco Infra Tech Ltd. The contract includes construction of an underground powerhouse cavern for four 130MW Francis turbines, an underground transformer cavern, two 16m diameter x 60m high surge shafts, four 5.4m diameter pressure shaft, two 570m long tailrace tunnels and two 6.5km long headrace tunnels. The project, for the National Hydroelectric Power Corporation of the Indian Government http://www.nhpcindia.com, is located at Tarkhola near Rangpo in district South Sikkim. It is to be completed in 44 months.

- Other hydropower projects with World Bank financial support in India include the 412MW Rampur project downstream from the Nathpa Jhakri installation on the River Satluj in Himachal Pradesh, and the 444MW run-of-river Vishnugad Pipalkoti scheme on the River Alaknanda in Uttarakhand. The Rampur Project is in the project appraisal stage and the Vishnugad-Pipalkoti project, in the same watershed as the Tapovan-Vishnugad project on which Alpine Meyreder/HCC are working, is in the early stages of preparation.