Contractors call for risky NY Harbor crossing

Sep 2009

Paula Wallis, TunnelTalk

- The 'Big Apple' is looking for qualified contractors willing to take on a high risk crossing under the New York harbor. The 1.75 mile crossing just north of the Verrazano Bridge, to replace the existing water siphons between Brooklyn and Staten Island, is considered one of the greatest tunneling challenges ever undertaken by the city.

- New York City Economic Development Corporation (NYCEDC) is inviting construction firms to submit a Statement of Qualifications (SOQ) for the project with a deadline of September 23, 2009.

-

1920's construction method

- A comprehensive harbor deepening program to accommodate the next generation of cargo mega ships calls for the replacement of two existing water lines with one deeper water pipe.

- The existing sihpons were laid in the early 1900's as part of massive engineer feat to deliver water from the Catskill Mountains in upstate New York to the five boroughs of New York City, The project included 18 miles of hard rock tunnels some 200ft to 750ft below the streets. The two water siphons crossing the Narrows, between Brooklyn and Staten Island were laid in trenches on the bottom of the harbor.

- In her 1937 book, 'Mighty engineering feats: clear and concise descriptions of ten of the of the greatest American engineering feats', Harriet Salt described the construction as, each line "made up of twelve foot lengths connected by flexible joints, was laid from a barge to which a curved bridge was attached and submerged to the trench. As each section of the flexible line was joined on the barge, the bridge supported it and lowered it to the trench, the dredge boat and the barge moving forward as the pipes were added to the line." (Fig 1)

- Some 90 years later their replacement design calls for a 12ft (3.66) TBM excavated diameter followed by pre-cast segmental concrete lining. Conventional steel reinforcement will be used in anticipation of low horizontal in-situ stresses and resulting bending movements in the lining.

-

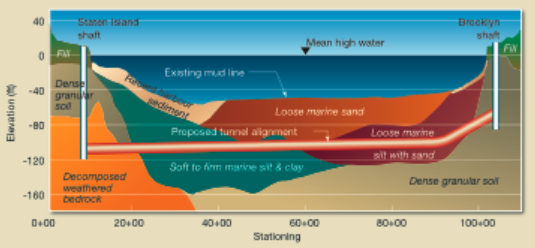

Fig 2. Aligment geology

-

A 6ft diameter, welded steel pipe within the tunnel will serve as a backup water supply line when the existing Richmond Tunnel is taken out of service. The design also calls for a 8ft diameter welded steel riser pipe in each of the two shafts, extensive land piping with pipe sizes ranging from 20in-72in diameter welded steel water mains and 10in-36in diameter sewers, and a new Chlorination Station. The new siphon is designed for a maximum flow rate of 570million leters per day (150 MGD).

- The TBM will be launched from the Staten Island shaft that will be approximately 115ft deep with an internal diameter of 28ft (8.5m). The Brooklyn side shaft will be roughly 80ft deep with an internal diameter of 24ft (7.3m).

- The CDM/HMM VJ has been engaged to provide engineering services to the NYCEDC who is managing the project on behalf of the New York City Department of Environmental Protection (NYCDEP), owner of the siphons.

- Marine borings show a significant variation in both clay and sand with full hydrostatic conditions along the 9,460ft alignment (Fig 2). Ground conditions, plus the limited cover in the channel demand a closed faced TBM. The type hasn’t been specified and will likely be left for the contractor to determine.