East Side Access soft ground tunnels awarded

Oct 2009

Paula Wallis, TunnelTalk

-

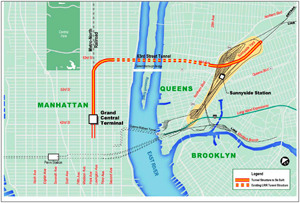

Fig 1. East Side Access alignment

- Traylor Bros will lead the tunnelling operations for the Granite/Traylor/Frontier JV after being awarded the soft ground tunnels for the $7.2 billion East Side Access project in New York City. (Fig 1).

- The soft ground bored tunnels in the Queens area of the project is the second large tunneling contract to connect the Long Island Railroad (LIRR) commuter lines in Queens to Grand Central Station on the east side of Manhattan.

- Project owner MTA (the Metropolitan Transportation Authority), awarded the contract on September 28 following a negotiated procurement process with a select list of bidders. The contract comprises four 19.5ft (5.85m) i.d. tunnels for a total length of 10,500ft (3,200m), plus reception pits for three tunnels and three shafts for emergency access and ventilation.

- The contract will also include elements of the Northern Boulevard underpass contract that has been split into different sections following termination of the initial contract. Completion of the slurry wall around a 760ft (230m) long open-cut excavation with the semi-circular TBM launch wall on the west end has been incorporated into the Queens Tunnel contract. The 120ft (36.5m) long NATM underpass of Northern Boulevard to connect the existing open-cut shaft that provides access to the Manhatten drives through the existing 63rd Street immersed tube crossing of the East River, will be bid in the near future. Underpass of the multi-transport corridor, that comprises both elevated and underground subway lines and the four lane surface road, is designed with ground freezing providing pre-excavation support.

-

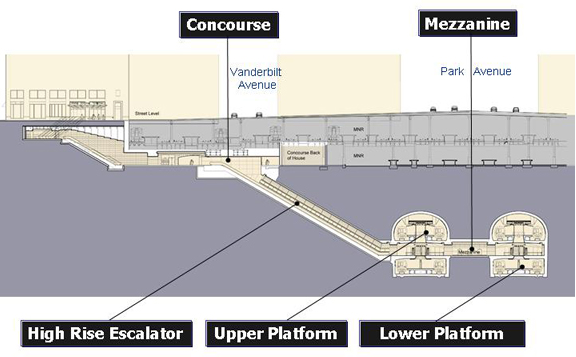

Fig 2. Detail of the Queens tunnels

- The Queens segment of the project pose several technical challenges, including difficult ground conditions, fast moving trains running over the alignment and the first use of slurry technology in New York City. The alignment is almost entirely in soft ground. The water table is at the surface in the Sunnyside Yard and about 15ft (4.5m) below the surface in Harold Interlocking. With the added element of random cobbles and boulders, the geology calls for tunnelling through mixed face construction.

- Traylor Bros has confirmed the purchase of two Herrenknecht slurry Mixshields for the excavation of the four drives that will connect the LIRR tracks to the 63rd Street East River tunnel and into the new hard rock tunnels and massive new underground station caverns under Grand Central Terminal both of which are currently under construction by the Dragadoes/Judlau JV.

- As the first use of slurry TBMs in New York City, the machines will be designed to bore through rock, mixed face and dense glacial till. They will be equipped also with a compressed air chamber for entry into the plenum for cutterhead inspections and for removal of unchartered manmade obstructions that are likely to be encountered on the drives under the rail yards.

-

Manhattan tunnels alignment

- The design calls for a one-pass, gasketed, doweled and bolted, 12in (300mm) precast concrete liner, heavily reinforced to withstand the considerable train loads in the areas of shallow ground cover.

- The relatively shallow tunnels will run under Harold interlocking, the busiest railroad interlocking in the United States, and under Amtrak's Sunnyside Yard.

- With the alignments running under multiple tracks of the rail yards and under the existing main line that carries trains moving at more than 60 miles an hour, ground settlement will be monitored in real time with an extensive automatic and manual monitoring system.

- Soil and groundwater loads will place the 82ft wide x 60ft deep (25m x 18.2m) semi-circular slurry launch wall in compression, creating a horizontal arching effect that will maintain stability with minimal reinforcement. A 35ft wide ground treatment zone is required behind the launch wall to prevent ingress of sand and water as the TBM makes its initial cut. According to project designer Parsons Brinckerhoff, the working site is the largest launch shaft in the world followed by the large circular launch shaft for six TBM drives on the French side of the Channel Tunnel project in the 1980-90s.

- To support the two Herrenknecht Mixshields, Traylor has ordered a separation plant from MS of France.

-

New LIRR station

- Meanwhile excavation continues on the Manhattan side of the project where the Dragados/Judlau JV holds the $434 million Manhattan tunnels contract and the $734 million contract for the excavation of two large station caverns using roadheaders and drill+blast. The two caverns lie 140ft (43m) below Grand Central Terminal and will accommodate four platforms in a two above two configuration in each cavern plus a mezzanine level. For the running tunnels the JV is using two 22ft (6.7m) diameter rock TBMs - a double shield SELI TBM and a Robbins main beam gripper TBM. Altogether the TMBs will bore two approach tunnels starting at the bulkheads of the existing 63rd Street Subway tunnel at Second Avenue, and continuing under Park Avenue where they branch off to bore four tunnels under Manhattan and branch again to excavate eight tunnels into the new station platform caverns under Grand Central Terminal and back to a four tunnel configuration for continuation to the storage yard under East 38th Street and Park Avenue.

- MTA confirms that the two TBMs have completed the two approach tunnel as well as the upper four drives into the top of two vast station caverns each of which will accommodate four station platforms. The Robbins machine has since begun its first of four lower drives while the SELI TMB is soon to begin its third drive.

- Trains carrying an expected 160,000 people daily are due to begin running through the completed project in 2014.

- East Side Access Optimization - TunnelTalk, Oct 2009

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.