Shani Wallis, Editor

- Design and construction management of nearly 50,000ft (15km) of new sewer tunnels under the historic city center of Charleston, South Carolina has received the 2009 Engineering Excellence Honor Award from the State’s division of the American Council of Engineering Companies (ACEC).

- The accolade is presented to consultants Black & Veatch and local consulting partner Hussey, Gay, Bell & DeYoung, Inc (HGBD) who in association designed and managed construction of the multi-phased, $123 million tunneling scheme.

-

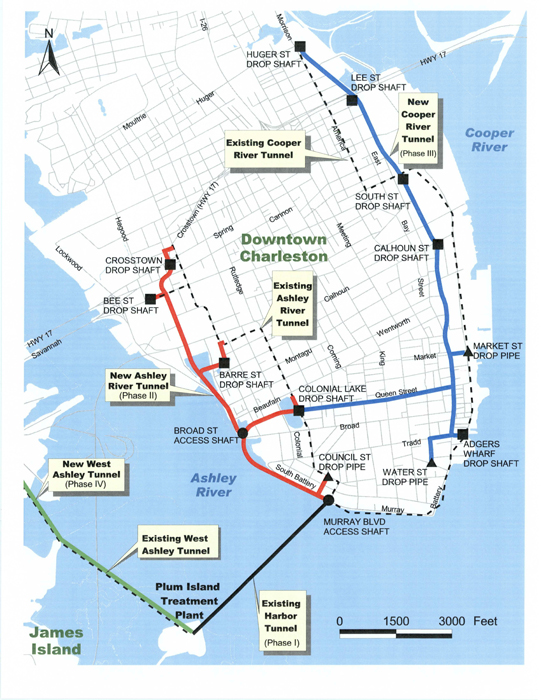

Plan of the new sewer collectors

- Under construction for nearly four years, the project is the backbone of Charleston’s wastewater collection system. It is South Carolina’s largest ever sewer infrastructure project and the largest ever capital works program implemented by Charleston Water System, the city’s water and sewer public utility.

- “This project became our highest priority,” said Mark Cline, Charleston Water System’s Capital Projects Officer. “Routine inspections in the 1990s discovered severe deterioration of the carrier pipe and several partial tunnel collapses in the system that was built in the 1960s/1970s. Hydrogen sulfide and sulfuric acid generated by restricted ventilation of the system had attacked the precast concrete carrier pipe and the steel ribs of the ribs and lagging support of the tunnel, which had been left open for future inspections. Realizing that further collapse was possible, we moved quickly to implement a total replacement rather than a rehabilitation program of the collector system, and we couldn’t have chosen a more competent project team and contractor to complete the project in such a timely and professional fashion.”

-

Wet caisson shaft sinking

- ACEC awards are evaluated on originality; future value to the engineering profession; perception by the public; social, economic and sustainable development considerations; complexity; and successful fulfillment of the client/owner’s needs, including schedule and budget. In all cases, the team associated with the sewer replacement project excelled. Successful incorporation of the extensive tunnel system into culturally and historically significant urban areas presented special challenges for project design and construction management. Essential program elements, included property acquisition, construction work sites, neighborhood impacts, vibration and settlement monitoring of historic structures, environmental assessments, permitting, cultural/historical approvals, geologic constraints and seismic considerations. All had to be managed and controlled effectively and with expertise.

-

Project data

The award-winning program centers on a network of three tunnel packages designed to convey wastewater from the full service area to the Plum Island Wastewater Treatment Plant across the Ashley River. Ranging in diameter from 5ft to 8ft (1.5m to 2.4m) and constructed at up to 120ft (36m) deep, the system comprises the 12,000ft (3.6km) tunnel under the Ashley River; the 18,000ft (5.5km) Cooper River tunnel that includes another under river crossing, and the 19,000ft (5.8km) Daniel Island extension.

-

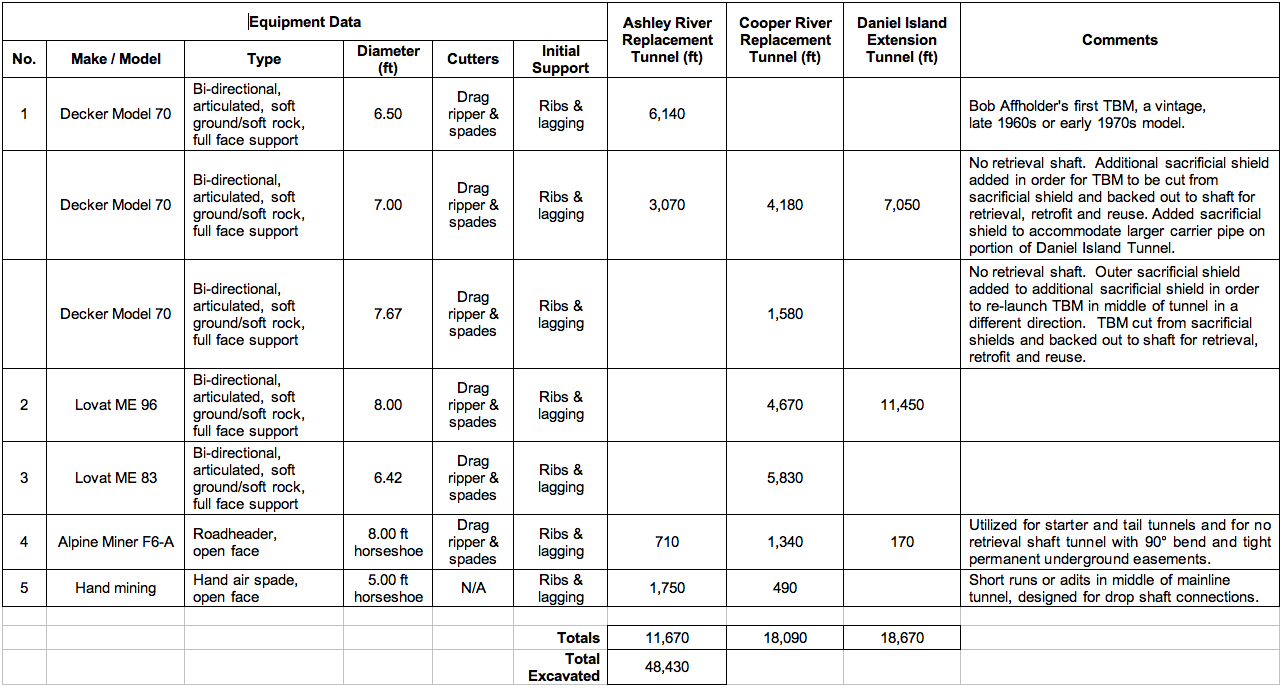

Table 1. Summary of the contracts signed with Affholder to excavate and complete the new sewer tunnel project

- All of the tunnels and their associated shafts and civil works were completed by Affholder Inc, the lowest bidder of three separate contracts totaling $90.5 million (Table 1). Each of the first two competitive bid contracts were awarded very close to the Engineer’s Estimate and the third was awarded as a fast-track negotiated contract after the client issued a invitation of expressions of interest.

- All tunnel and shaft excavations are through the two main geologic deposits beneath Charleston. The upper 40-60ft deep deposit is of estuarine and marine soils referred to as surficial deposits or ‘pluff’ mud, which has a high moisture content, low strength and a soft to very soft consistency. Underneath is the Cooper Marl, a 250ft thick calcareous cemented, finely granular material that has no distinguishable stratifications, beddings, or joints and is an ideal tunnel medium, strong enough to stand up on its own yet soft enough to be easily excavated.

- Affholder used a range of different methods to suit the geological conditions from hand-mined headings and roadheaders in the Cooper Marl to open-faced and closed face EPBM TBMs as necessary when working in the surficial deposits and mixed ground conditions (Table 2). Steel ribs and wood lagging served as the initial lining of all the tunnels with 20in to 54in Hobas pipe back-filled into the tunnels to provide the corrosive resistant carrier pipeline.

- To protect against settlement due to ground loss and groundwater depletion in the surficial soils beneath the city’s historical heritage, all large-diameter shafts were specified as wet caisson structures. Once socketed into the Marl and dewatered, shaft excavations were taken to depth with steel ribs and hard wood lagging. A final concrete lining with an epoxy coating protects the shafts from the corrosive wastewater environment. Micrtounneling with a 39in-diameter RVS 350AS Soltau slurry-based microtunneller, was used effectively to connect the near-surface gravity lines to the new drop shafts of the new deep level collectors.

- To work in the particular geological conditions under Charleston and on the particular design needs of the project, Affholder was required to apply innovative means and methods. Among these was development of an oversized skin for its tunnelling shields that allowed the machines to be cut out of the skin and remove back through the smaller diameter of the supported tunnel on three of the eight TBM tunnel drives. On the shaft sinking work, Affholder’s implementation of a braking system to control the sinking rate to address a concern that some of the caissons might not stop sinking into the weak soils after each lift was added.

-

Tunneling through the Cooper Marl

- On the management side, the client secured bonds to fully fund the full capital investment program and held a contingency on the contracts that allowed for prompt payment of change orders and agreed claims for time and money compensations as they arose. The client was also persuaded to engage a DRB (disputes resolution board). The other major plus for this project is that when the inevitable problems arose (and there were several), the Owner (City of Charleston Commissioners of Public Works), Engineer (Black & Veatch with HGBD a local engineering company) and Affholder all worked together to resolve problems. There were claims on the project but no disputes and the DRB commended the entire team for their efforts.

- According to David Egger, Global Practice Leader for tunneling for Black & Veatch’s water business, the program’s success can be attributed to an exceptional relationship among Charleston Water System, Black & Veatch, HGBD and Affolder as they combined their expertise for the community’s benefit. Local residents and millions of tourists each year will benefit from the infrastructure improvements.

- “Risk management and anticipation of concerns before problems could manifest was an ongoing discussion among the owner, engineer and contractor management team from planning through startup operations,” said Egger. “The sum of this team produced results that were much greater than any of the parts, which makes this an example of engineering and construction at its best.”

-

Installation of a drop pipe

- Unfortunately, the success of its work in Charleston did not save Affholder from being closed in early 2007 by its 100% parent company Insituform, that decided to focus more aggressively on its core business of sewer rehabilitation and eliminate its exposure to the contracting industry.

- In the meantime, the new network of sewer tunnel collectors was commissioned in 2008 and all flow has been diverted away from the old system and into the new replacement system. The tunnels of the old system remain open and a program is being planned to secure these old structures and remove any future risk of further tunnel deterioration or collapse.

- For the completed replacement sewer program and its design and construction management companies, the project is eligible, as one of six finalists in South Carolina’s ACEC awards competition, to compete for the national ACEC awards. Local firm HGBD offers civil, water, wastewater, transportation, environmental, geotechnical, and structural engineering as well as architecture and support services for planning and design for a wide array of projects. Black & Veatch is a leading global engineering, consulting and construction company specializing in infrastructure development across a broad line of service expertise. With $3.2 billion in revenue, the employee-owned company has more than 100 offices worldwide and has completed projects in more than 100 countries on six continents.

Ross Webb, Consultant and Project Manager for Affholder on the Charleston contracts

Mar 9, 2009

The project in Charleston was one of the best from any measure. The success of any project, especially when difficult ground or other conditions are encountered, is due to the people who are building it. That group of people includes those working for the contractor, owner and engineer. Unfortunately, it's rare to find every one of those positions filled with top notch folks as they were in Charleston.

Affholder grew from a profitable small tunnel contractor to a large tunnel contractor in three years and then lost most of its senior management over the next two years as profitability declined. Insituform, the publicly traded parent company, had pushed for growth but didn't want the growing pains that came with such a rapid expansion. Even though Affholder was showing strong signs of recovery in 2007 the decision was made to cut risk and liquidate. Interestingly the Insituform executives who made that decision were also gone within two years. But by then it was too late for Affholder. It was sad to lay off employees who had been like family, many with twenty-plus years of service. The tunnel industry is such that quality folks, such as those, are quickly rehired. Hopefully they can carry some of the old Affholder "can do" spirit to their next jobs.