Brightwater update

Aug 2008

Shani Wallis, Editor

-

Two of the four soft ground TBMs on the Brightwater Project north of Seattle are well into their strides, a third is launched, and the fourth is due to arrive this month for assembly in July and launch in August.

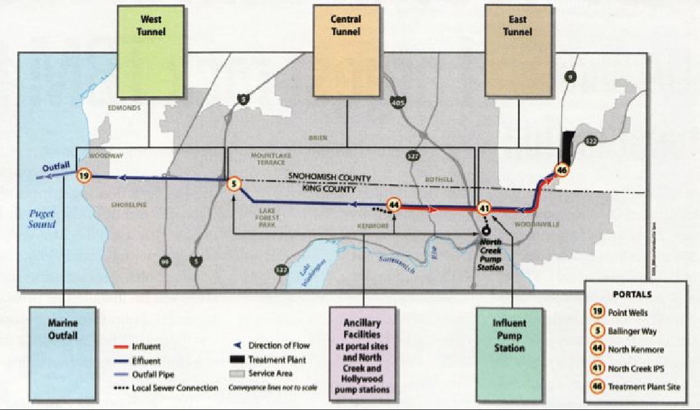

- The first TBM launched, a Lovat EPBM for the Kenny/Shea/Traylor JV's East Tunnel contract, is 5,400ft (1,645m) into its single 14,050ft (4.28km) long x 19ft 3in (5.9m) o.d. heading.

-

Fig 1. Plan of the project’s three tunnel contracts

- The first of two 17.4ft (5.3m) diameter Herrenknecht slurry Mixshields working on the Central Tunnel contract for the Vinci/Parsons RCI/Frontier-Kemper JV is 2,500ft (762m) into its 11,600ft (3.5km) east drive to the Kenny/Shea/Traylor influent structure working shaft at North Creek after launching in early August 2007. The second machine, working in the opposite direction from the 55ft i.d. x 90ft deep (16.8m x 27.5m) North Kenmore shaft, is just 100 rings or 500ft (152m) into the 20,100ft (6.2km) west drive to the Ballinger Way shaft.

- The fourth machine for the project, due to arrive at the end of this month (June) is another new 15ft 5in (4.7m) diameter Lovat EPBM to be used by the Jay Dee/Coluccio/Taisei JV to complete the 21,100ft (6.4km) West Tunnel contract. It will progress the Point Wells site of the ocean outfall pipeline on Puget Sound (to be built by a different contract under a different contract) east towards the Ballinger Way shaft.

- All four TBMs are working through waterbearing glacial geology the most complex being on the Central Tunnel where the alignment is 40-475ft (12-144m) below ground level and potential working pressures for the Mixshields are more than 7 bar. Montgomery Watson Harza/Jacobs Associates (MWH/JA) with geotechnical engineer Camp Dresser McKee (CDM) are tunnel designers of the design-bid-build contracts for the County's Wastewater Treatment Division of the Department of Natural Resources and Parks. To cope with the anticipated conditions, the contracts specified soft ground EPB or slurry tunneling as well as through-the-tailseal annular grouting.

- Progress, according to Leon Maday, Country Project Representative on the East Tunnel, is having its "ups and downs. There are no major incidents to report and there has been no problems with meeting boulders or other obstructions. TBM 1 on the East Tunnel has recorded rates of 540ft (165m) in a week of two 10h shifts/day, six days/week and is averaging 350ft/week but is about three months behind planned progress. The two Mixshields have had a tough time mining in zones of high clay content with rates constrained at times by the separation plant. Last week, which was a short four-day week, the leading Mixshield recorded an advance of 240ft (73m) working three 8h shift/day. The JV however, gained some time on anticipated launch of the second machine from the same central working shaft. The machine for the West Tunnel will arrive shortly but is about two months behind the planned schedule. All is prepared, however for its launch in August."

- At the same time, the 205ft deep x 21ft i.d. Ballinger Way shaft (62.5m x 6.5m) is progressing as a ground freezing operation by subcontractor Moretrench. "The freeze has been applied very well," said Maday, "and excavation is advancing at about one ring or 5ft/day installing a primary lining of steel ribs and lagging. This is grouted up as they go to control a zone of contaminated soil and the shaft will be lined with a final in-situ lining."

- Precast concrete segments for all three tunnel contracts are being produced and supplied by CSI-Hanson at a custom built facility in Tacoma about 45 miles south of the project. All are steel-fiber reinforced segments with six bolted, dowelled and gasketed segments in each 5ft long x 10-13in thick ring (1.5m x 250-325mm). Hatch Mott MacDonald designed the linings and CSI segment lining consultants John Hart and Len Worden are directing the casting operations.

-

NAT 2008 conference references:

Establishing geotechnical baseline values for deep soft ground tunnels:

Tuesday, June 10, 8.30am, Track III

Jet grout ground modification for the Brightwater conveyance system:

Wednesday, June 11, 8.30, Track 1