Slurry TBMs ready to tackle New York ground

Mar 2011

Paula Wallis, TunnelTalk

- Two Herrenknecht slurry TBMs are poised to begin the short, but challenging soft ground tunnels on the $7.3 billion East Side Access project to bring Long Island Rail Road services into Grand Central Station in Manhattan, New York.

-

Mixshields ready to launch - Tess above, Molina below

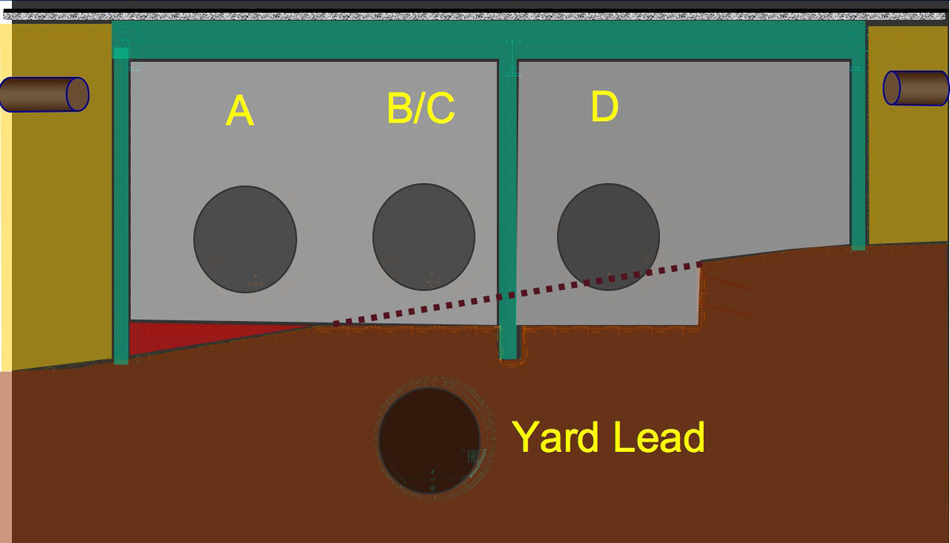

- Officials dedicated the 22ft (6.7m) diameter machines, named Tess and Molina by local school children, last week (March 18). They are tasked with two drives each. Tess will bore the A tunnel, for in-bound trains to Manhattan, and the D tunnel for outbound trains and Molina will complete the Yard Lead drive, to take trains to and from the mid-day storage yard, and the B/C tunnel, which is a contra-flow tunnel for inbound trains in the morning and outbound in the evening (Fig 1).

- "TBM Molina is in the trench and it is connected up and electrical testing is underway towards an April 18 start," said Andy Thompson of Hatch Mott MacDonald and Program Manager for construction. "Molina will start with the Yard Lead tunnel, which is the longest drive at about 4,000ft (1,219m). When it reaches the reception pit, the shield will be retrieved and the trailing gear backed through the tunnel to start the B/C drive. Once completed, the machine will stay in place until surface track relocation allows sinking of a shaft to retrieve the cutterhead and finish the approach structure."

- The second machine is scheduled to launch six weeks after the first, and will drive the 1,900ft (579m) tunnel A first, followed by the D tunnel. The TBM will be launched in stages to navigate around the piles of an existing bridge that crosses the open cut construction.

- The identical slurry machines supplied by Herrenknecht will tackle the most challenging conditions of the entire East Side Access program. Their drives are mostly in soft ground, with mixed faces, boulders, and manmade obstacles, a high water table, low overburden, and the nation's busiest railroad interlocking junction overhead. The first machine has an additional component to manage. "The first 300ft (91m) of the Yard Lead drive is in rock," said Thompson. "A 100ft (30m) interface zone of mixed face conditions follows and the remaining 3,600ft (1097m) is in soft ground with boulders."

- This is one of only a handful of slurry machine projects to date in the United States and a first for New York and for the local union Sandhog workers. The other Herrenknecht Mixshield projects in the US include, the Pittsburgh North Shore Connector, the Portland CSO projects, and the Brightwater project in Seattle.

-

TBM cutterheads dressed with mono-block cutters

- Contractor G.T.F., a three-way joint venture comprising Granite Northeast, Traylor Bros, and Frontier-Kemper, won the contract in September 2009 with a bid of $730 million. "We worked to overcome the limited slurry experience by soliciting requests for proposals," said Thompson. "The team selected includes Traylor Bros as one of the contractors in the country with extensive soft groundTBM experience."

- Thompson said the TBMs are standard slurry machines, but that the JV with manufacturer Herrenknecht has over engineered them so as to reach safe havens located about every 1,000ft (304m) along the tunnel alignments and limit the need for compressed air interventions. "The cutterheads have a lot of hard facing and are fitted with mono-block cutters," said Thompson. "Boulders can often shatter a cutter ring and the whole disk is lost. The mono-block cutters, being a single casting, will prevent this."

- One of the three safe havens is where the three-tunnel emergency exit was located, where the A tunnel, as well as the Yard Lead and the B/C tunnels all meet. The emergency shaft was deleted from the plans, and the safe haven creation originally by jet grouting was replaced by a major ground-freezing project, conducted by freezing specialist subcontractor Moretrench. The machines will be driven into the block of frozen ground, where maintenance will be conducted in free air, and the ground freeze thawed after construction.

-

- The machine launch is about six weeks behind schedule, mainly due to the significant repair work by the contractor to fix the slurry walls around the open launch box structure. These were installed under a separate contract that was terminated for default. There has also been a design change of the launch box, said Thompson. "Instead of doing a huge amount of jet grouting outside the slurry wall, we decided to move the jet grouting inside the slurry wall, effectively building three concrete launch blocks within the slurry wall structure itself, into which the TBM's will be installed and pressurized before mining through the walls.These will remain as part of the permanent works," he said.

- Transition to the underground

- The Queens tunnels will link tracks on Long Island to the existing 63rd Street Tunnel under the East River, and to the East Side Access Manhattan tunnels and new terminal under Grand Central station.

- As the soft ground tunnel excavation begins under Amtrak's Sunnyside Yard, and Harold Interlocking in Queens, the hard rock drives in Manhattan are winding down. The double shield Seli machine has 1,700ft (518m) left to complete the second of its two drives, and is on schedule to finish by late May. The Robbins main beam gripper TBM wrapped up its second drive last May and contractor Dragados/Judlau JV is now in the process of removing the machine.

- Dragados/Judlau holds both the $434 million Manhattan tunnels contract and the $734 million contract for the two large station caverns, which are being excavated using roadheaders and drill+blast. According to Thompson, the station caverns contract is running somewhat behind schedule. "The top heading in the west bound cavern is complete but there is still some bench excavation to do at the south end. However the first 300ft of the north end in the same cavern has the mud slab in, the waterproofing membrane is applied and the formwork for casting the final lining is being installed for a first concrete pout in the coming days. With parallel caverns, a few cross passages have been opened up to bypass the concrete works and complete excavation in the south end. The eastbound cavern is about a month behind."

- Meanwhile, excavation on the last piece of the link is yet to start. The Northern Boulevard Underpass, to connect the Queens Tunnels to the existing 63rd St tunnel and the immersed tube under the East River is a NATM operation awarded to the Schiavone/Kiewit Jin February 2010.The small but complex operation it for excavation of a 120ft long by 64ft span (36m x 19.5m) NATM heading under the Northern Blouevard corridor which comprises a subway box, the highway at grade and an elevated subway structure. Ground freezing is being installed to support the excavation and the JV is currently excavating the core down within the existing slurry wall, putting in temporary bracing, drilling in the freeze and ground treatment pipes, and will be into excavation by the end of the year.

- The Queens Tunnels contract is scheduled to be complete by 2013. The overall project, which consists of more than 30 construction packages, is on schedule to be completed in 2016.

- East Side Access soft ground tunnels awarded - TunnelTalk, Oct 2009

East Side Access optimization - TunnelTalk, Oct 2009

|

|

|

|

|

Add your comment

- Thank you for taking the time to share your thoughts and comments. You share in the wider tunnelling community, so please keep your comments smart and civil. Don't attack other readers personally, and keep your language professional.