Second TBM breakthrough into the station box at Frederiksberg Allé on Monday afternoon (9 March) marks the latest achievement for the Salini/Seli/Maire Tecnimont JV as excavation of the 15.5km of twin running tunnels for Copenhagen’s Cityringen Metro line approaches one-third completion.

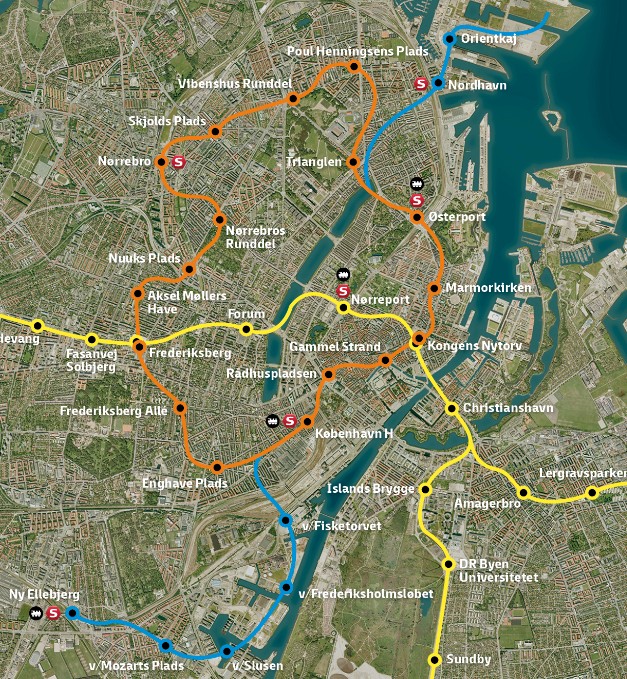

For the contractor, scheduling and logistical flexibility in its working relationship with metro operator and project owner Metroselskabet has been a key factor in driving the project towards a 2019 opening. Initial project scope – which included construction of a crossover cavern under the lakes at Øster Søgade in anticipation of TBM break in of the separate Nordhavn (North Harbour) extension [awarded in 2014 for a contract price of €310 million to the Hochtief/Züblin JV] – is now extended to facilitate advance construction of the future underground connection structure with the planned Sydhavn (South Harbour) extension (Figure 1).

Metroselskabet’s Cityringen Project Director, Guy Taylor, told TunnelTalk: “We decided in 2014 to increase Cityringen project scope by taking a southern extension project on (Sydhavn).” The new extension will begin half way between the ramp that brings the running tunnels up to grade near what will be the control centre and maintenance yard to the south, and the Sønder Boulevard bifurcation shaft where the maintenance spur breaks into the main ring.

“At this location – in Havnholmen – we are in the process of building another bifurcation chamber that will mean the tunnels can turn off the route towards the depot and continue heading in a southerly direction towards a large area of the city that is due for redevelopment (Sydhavn),” said Taylor. The contractor is currently in the process of constructing the diaphragm walls for that structure.

“A decision was made to add to the Cityringen tunnelling contract scope so that in the future, when we complete the Sydhavn project, we just need to break into this box to complete the connection. That is going to be many years from now, but we are building this advance structure to prevent interrupting the operational railway in the future.

“We finalised agreement with the contractor to extend the contract scope in the middle of last year (2014), shortly after funding approval to facilitate the Sydhavn extension was granted by the government,” explained Taylor. Final Parliamentary approval for the project, however, was not actually granted until earlier this year. Coincidentally this was in the same week as the headline-grabbing double breakthrough of TBMs Minerva and Eva into Copenhagen’s main Central Station (January 2015) at the end of their 1,335m drives from the launch ramp at Otto Busses via the Sønder Boulevard shaft – one of only three shafts servicing all of Cityringen’s TBM operations.

Excavation of the additional bifurcation shaft at Havnholmen forced a late rethink of the whole TBM drive strategy even as the four Seli/Kawasaki EPBMs selected to complete the running tunnels were already in the ground.

“The new shaft affects the remaining logistics of the project and we have had to change the TBM sequencing in consideration of this,” said Taylor. Under the original plan TBMs Minerva and Eva were due to be dismantled after completing their drives into Copenhagen Central, then transported the short distance back to the Sønder Boulevard working shaft for reassembly, followed by short clockwise drives through to Frederiksberg Allé (Fig 2).

Under the new schedule, and following breakthrough at Copenhagen Central in January (2015), the machines are currently being dismantled and transported across the city to the Nørrebroparken shaft for clockwise excavation of the northern section through to the Oster Søgade shaft (Fig 3). Instead, TBMs Nora and Tria, which were due to end their anticlockwise drives at Frederiksberg Allé, are being driven all the way through to the Sønder Boulevard shaft from where they will be transported to Oster Søgade for the final clockwise drives through to Copenhagen Central on the eastern side of the ring.

As of this week TBM Tria had broken through the headwall into Frederiksberg Alle, where routine maintenance will now be performed, while her sister machine is slightly ahead having advanced 200m towards the next station at Enghave Plads. These drives are expected to be completed by May/June (2015), and in the meantime TBMs Eva and Minerva will be reassembled in the Nørrebroparken shaft ready to begin their excavation of the northern section of the ring once Tria and Nora complete their drives.

“By amalgamating the two tunnelling drives in the south into a single operation we can get the new shaft built without interrupting the main project logistics and sequencing,” said Taylor. “Eva and Minerva won’t be relaunched until Tria and Nora have completed their drives into the shaft at Sønder Boulevard because we won’t service four machines from the same working shaft [Nørrebroparken]. Had we not made these changes to the schedule it would have meant occupying the tunnelling worksite at Sønder Boulevard for up to a year, which could have meant unnecessary project delays.”

Excavation is by four 5.78m diameter Seli EPBMs manufactured at the company’s workshops in Aprilia, Italy. Through a licensing agreement, Kawasaki of Japan has designed and supplied the drive unit and screw conveyor components to fit with the Seli cutterhead, shield and backup design and fabrication.

Since launch from Nørrebroparken in August 2013 TBMs Tria and Nora have achieved breakthroughs into five station zones for a total distance of 3,400m. Tunnel Manager Simon Taylor said: “We now have a very high level of confidence in the machines, and have achieved progress rates of up to 20 rings/day (28m) – considerably better rates than was programmed for. The TBMs have proved more than able to deliver the average tunnelling rate of 10 rings/day that we needed for the project – we can keep up with that and improve upon it.”

As expected, geological conditions have been predominantly competent limestone, although more challenging and highly fractured conditions are being experienced during approaches to, and on break out of, the station zones. The machines are designed to withstand 9 bar working pressures in anticipation of maximum 4.5 bar operating pressure commensurate with an alignment that runs under a high water table.

“We knew from previous experience excavating the first phase of the metro that the limestone in itself doesn’t give particularly high cutting tool wear,” said Simon Taylor. “There are some flint bands in the limestone that can give you some impact wear, but generally speaking the limestone isn’t too compressed. However, up into the fractured limestone and mixed face conditions with the glacial tills, we are experiencing higher levels of abrasive wear. This is experienced most noticeably in the approach to, and just after leaving the stations, but this is to be expected because the TBM drives have to climb up [from the limestone band] to the stations, otherwise these would have to be very deep. It’s a geometric constraint.”

So far average hydrostatic pressure has been recorded at 3 bar, although at the lowest elevations (40m deep) pressures of up to 4 bar have been recorded. Maintenance stops in each of the station zones, and between relatively short individual drive lengths averaging 700m long, are programmed for a duration of 2-3 weeks. This allows ample time for full inspections of the cutterhead and shield, and routine replacement of all the cutting tools.

“We are effectively starting each drive with a brand new cutterhead, and the short drive lengths along the alignment reduce the risk of having to perform maintenance between stations,” said Simon Taylor.

However, 30 interventions have been necessary outside the station zones. Eleven of these have been carried out in hyperbaric conditions in a general pressure range of 1.5 bar to a maximum 2 bar. The remaining 19 have been completed in free air conditions. “To give you an example, we had just left the station in Frederiksberg when maintenance became necessary. The clay till there had a very good stand up time so we managed to complete the work in atmospheric pressure,” said Simon Taylor.

Cityringen station design is for compatibility with the short three car train system that operates on already-existing lines of the Copenhagen Metro, meaning that the 17 station boxes, all excavated from the surface, can be relatively compact at 20m wide x 60m long.

Construction has been carefully timed to fit in with the three main phases of TBM operations so that the station boxes on the west and south of the ring are complete down to the base slab. Excavation of the stations to the north of the ring between the Nørrebroparken and Oster Søgade shafts is well under way in anticipation of the start of TBM operations in this zone from July (2015). The eastern section of the alignment between Oster Søgade and Copenhagen Central will be the last to be completed and here all the diaphragm walls have been constructed but top down excavation of the boxes has only just begun.

Project Director Guy Taylor explained the “hybrid” construction method being utilised for excavation of the boxes. “We do a secant pile perimeter wall, cast a permanent roof slab and then excavate using temporary struts and props to a base which is then cast. We then come back up doing a permanent in situ concrete lining and laying intermediate strutting slabs as we go, removing the temporary steel struts. So it’s a hybrid construction method– it’s got the permanent base slab, the permanent top slab, and in between the two, during construction, you have temporary steel props.”

Not included in current contract scope is excavation of the numerous pedestrian tunnels and escalators that will be required for the two Phase I metro interchange stations at Frederiksberg and Kongens Nytorv; as well as the pedestrian connections between the new metro stations at Copenhagen Central, Nørrebro and Østerport and their respective mainline surface level stations. “We are in the process of doing a design and procuring all this pedestrian access tunnel work through a separate contractor,” explained Guy Taylor.

“This work requires interfacing with so many stakeholders and rail operators and we wanted to retain overall design control. To let this work as part of the main turnkey design-build contract package would have been problematic because there were too many unknowns. We wanted to complete detailed engineering design and utility relocations at our leisure.” A contractor is expected to be appointed in time for delivery during the fitting out and M&E stages of the main Cityringen running tunnels.

Concrete segmental lining for the running tunnels is of a universal 5+1 design, with a ring width of 1.4m. Segments are manufactured by Mobil Baustoffe at a casting yard in Sassnitz in neighbouring Germany. Average production rate is 140 rings/week, with the segments being transported to Copenhagen on a weekly schedule by cargo ship on a roll-on/roll-off system. The units are stored at a site in Norhavn in the north of the city, for onward transportation to the relevant TBM servicing shafts. At the storage facility a stockpile of 5,400 rings is currently being maintained.

As tunnelling in the east and south draws to a close, valuable lessons have been learned in readiness for what are expected to be more challenging geological conditions to the north of the ring.

“We have done the easy bit of the tunnelling so far. There are some challenges from the summer onwards when we move to the north and expect to find much more of the mixed face conditions, so the learning curve so far has been useful in terms of gaining an understanding of the machines’ performance and control of the characteristics and behaviour of the ground.”

That the contractor has chosen to excavate the “easier” ground first is a deliberate strategy to gradually build up machine experience.

Originally Cityringen was planned as two separate contracts – one for the more geologically challenging northern sections and a separate one for the easier southern ones, with the dividing line between contracts being drawn across Frederiksberg and Øster Søgade. This might well have resulted in different machine selection for the northern alignment, said Taylor, but in the event letting the whole project as a single contract gave the winning contractor JV a greater degree of mining flexibility. “The contractor to some extent has had the opportunity to tunnel to suit his needs because the tunnel boundaries did not have to respect contract boundaries.”

As part of that initial bidding process – during which some of the contractor teams volunteered a combined price for both packages – it became clear through the evaluation stage that letting the contract as a single tunnelling package would make economic as well as logistical sense. So far this has proved a more than wise decision.

TunnelTalk will continue to report on project developments and milestones as and when they occur.

|

|

|

|

|